title:

In laboratories and small production environments, coaters are common equipment used to evenly coat liquid materials on a substrate or material surface. As two common coating machine models, wire rod type small coaters and blade type small coaters each have a series of advantages and characteristics. This article will conduct a detailed comparative analysis of these two coating machines so that readers can better understand their differences and applicable scenarios.

1. Overview of wire bar type small coating machine

The wire bar small coater is a device that uses wire bar coating technology to evenly coat liquid materials on the surface of the substrate. Its working principle is to evenly coat liquid material on the surface of the substrate through a wire rod to achieve automation and precise control of the coating process. Wire bar small coaters usually have smaller volumes and simple structures and are suitable for laboratories and small-scale production environments.

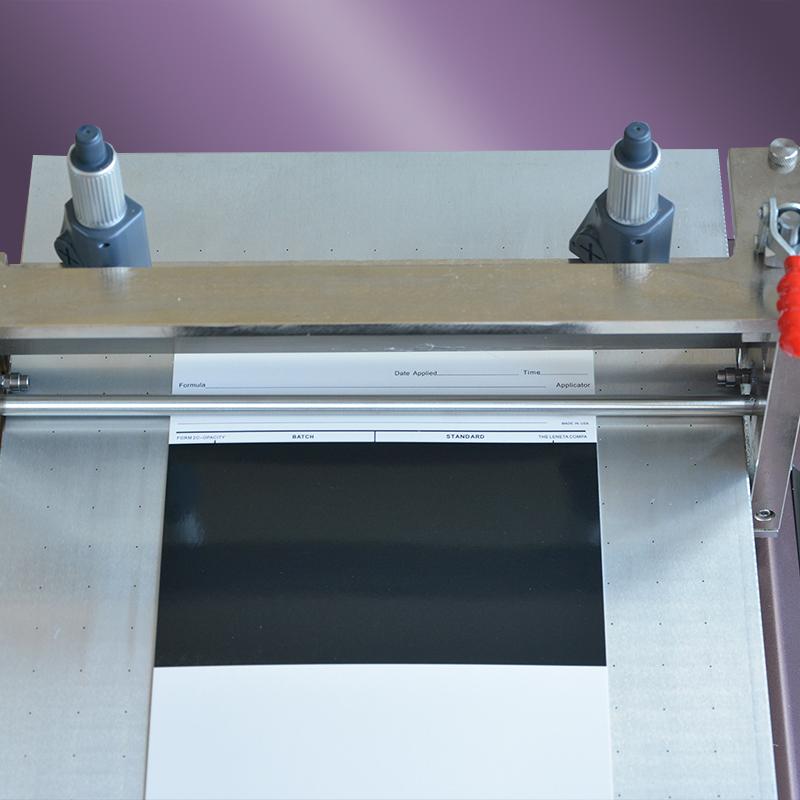

2. Overview of scraper type small coating machine

The small blade coater is a device that uses blade coating technology to evenly coat liquid materials on the surface of the substrate. Its working principle is to evenly coat the liquid material on the surface of the substrate through a scraper, and then use the scraper to scrape off the excess material to achieve precise control of the coating process and adjustment of the coating thickness. The scraper-type small coater has a relatively simple structure and is easy to operate. It is widely used in laboratories and small production lines.

3. Comparative analysis

The following will conduct a comparative analysis of the wire rod type small coater and the blade type small coater in terms of coating principles, coating effects, scope of application, etc.:

Coating principle:

The wire bar type small coater uses wire bar coating technology to evenly coat liquid materials on the surface of the substrate through the wire bar. The small blade coater uses blade coating technology to evenly coat the liquid material on the surface of the substrate through a blade and scrape off the excess material.

Coating effect:

The small wire Bar Coater has high coating uniformity and is suitable for scenes that require uniform coating thickness. The coating thickness of the scraper-type small coater has a wide adjustable range and is suitable for scenarios with different coating thickness requirements.

Scope of application:

The wire rod coater is suitable for scenarios where the viscosity of liquid materials is low and high precision coating uniformity is required, such as ultra-thin coatings, polymer material coatings, etc. The scraper coater is suitable for scenarios where liquid materials are relatively viscous and require adjustable coating thickness, such as hot melt adhesive coating, silicone coating, etc.

Operational complexity:

The wire rod coater is relatively simple to operate and does not require too much adjustment of the coating thickness. It is suitable for beginners and quick operation. The operation of the scraper coater is slightly complicated. The scraper angle and coating thickness need to be adjusted according to the coating requirements. It is suitable for users with certain operating experience.

4. Conclusion

Wire rod type small coaters and blade type small coaters each have their own advantages and disadvantages and are suitable for different coating needs and scenarios. The wire rod type small coater is suitable for scenes that require high coating uniformity. It is simple to operate and suitable for beginners and quick operations; while the scraper type small coater is suitable for scenes that require adjustable coating thickness, and the operation is relatively complicated. Suitable for users with certain operating experience. When selecting a coating machine, a reasonable selection should be made based on specific needs and coating requirements to improve the coating effect and production efficiency.