introduction

The self-adhesive tape coating machine is a professional equipment used to coat self-adhesive tape on the surface of the tape. This type of machine is widely used in various industries such as packaging, printing, construction, etc. This article will provide an in-depth introduction to the technical principles, operation methods and maintenance of the self-adhesive roll coating machine.

1. Technical principles

Coating mechanism

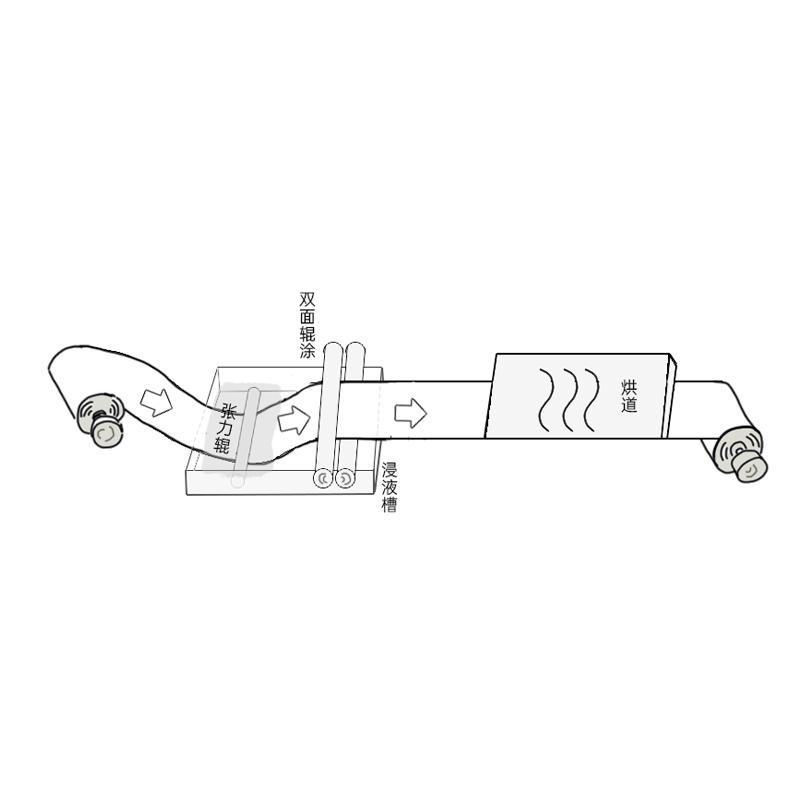

The core of the self-adhesive tape coating machine is its coating mechanism. The coating mechanism usually consists of a coating roller, a pressure roller, a coating knife and a control system. The coating roller is responsible for evenly coating the self-adhesive adhesive on the surface of the coil, while the pressure roller ensures appropriate contact pressure between the coil and the coating roller to ensure uniform coating. The coating knife is used to control the thickness of the coating layer.

Self-adhesive supply system

The self-adhesive supply system is responsible for delivering the self-adhesive to the coating mechanism. This typically includes self-adhesive tanks, pumps and piping systems. The pump is responsible for drawing the self-adhesive adhesive out of the tank and delivering it to the coating mechanism. The piping system ensures a steady and even flow of self-adhesive to the coating mechanism.

Control System

The control system is the brain of the entire coating machine. It is responsible for monitoring and adjusting various parameters of the coating mechanism to ensure the quality and stability of coating. The control system usually includes functions such as temperature control, speed control, and pressure control.

2. Operation method

Before operating the self-adhesive tape coating machine, some preparations are required. First, check that the self-adhesive storage tank has enough glue. Secondly, ensure that the coating mechanism and conveying system are in normal working condition.

According to the type and requirements of the coil to be coated, set the parameters of the coating machine, including coating speed, coating thickness, temperature, etc. The setting of these parameters directly affects the quality and effect of coating.

Follow the steps in the operating manual to start the coater step by step. First start the self-adhesive supply system to ensure that the self-adhesive can be smoothly delivered to the coating mechanism. Then start the coating mechanism and control system to ensure that all parts work in harmony.

During the coating process, operators need to closely monitor the operating status of the coating machine. Through the monitoring data of the control system, parameters can be adjusted in time to ensure the uniformity and stability of coating.

After coating is completed, gradually shut down all parts of the coating machine, including the coating mechanism, self-adhesive supply system and control system. Clean and maintain the coater to ensure it is in good condition the next time it is used.

3. Maintenance

Regular cleaning is key to keeping your coater running properly. Clean the self-adhesive residue on the surface of the coating mechanism, and clean the coating roller and pressure roller to ensure uniform coating. At the same time, clean the control system to prevent dust and dirt from affecting its normal operation.

Various parts of the coating machine require regular lubrication to reduce friction and wear and extend the service life of the machine. Be sure to use appropriate lubricants and perform lubrication maintenance as recommended in the operating manual.

Regularly check the electrical system of the coating machine to ensure the normal operation of cables, switches, sensors and other components. Repair or replace damaged parts to prevent electrical failure from causing damage to the coater.

Carry out regular comprehensive maintenance, including checking and calibrating various parameters of the coating machine and replacing wearing parts to ensure the stability and reliability of machine performance.

In order to ensure the safe operation of the coating machine, training of operators is essential. The training content includes the operating procedures, safety precautions, troubleshooting, etc. of the coating machine to improve the operators' skills and emergency response capabilities.

in conclusion

As an indispensable piece of equipment in modern industrial production, self-adhesive roll coating machines play a key role in improving production efficiency and product quality. Operators need to be proficient in the technical principles and operating methods of the coating machine, and perform equipment maintenance in strict accordance with the maintenance plan to ensure its long-term, stable and efficient operation. Through continuous technological innovation and equipment optimization, self-adhesive tape coating machines will continue to play an important role in various industries.