Glass fiber hot melt adhesive coating machine is an advanced material coating equipment, widely used in construction, automobile, aerospace and other fields. This article will deeply explore the technical principles, operating methods and technical requirements of this equipment, with a view to providing reference for related industries.

Part One: Technical Principles

1.1 Basic structure of glass fiber hot melt adhesive coating machine

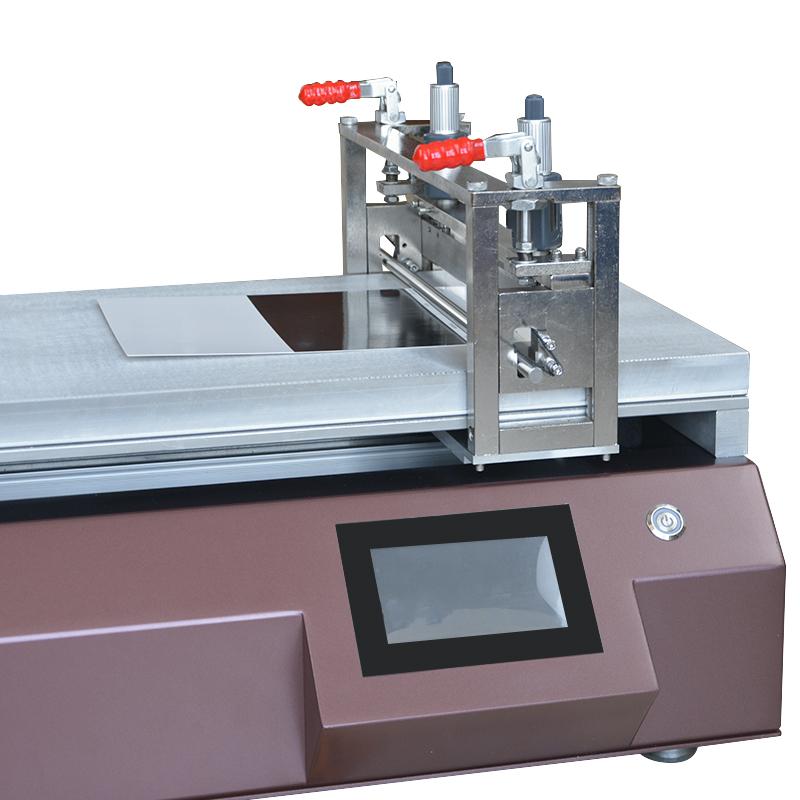

The glass fiber hot melt adhesive coating machine mainly includes an adhesive coating system, a melt adhesive supply system, a hot melt system and a control system. Among them, the glue coating system is responsible for evenly coating the melted hot melt glue on the fiberglass substrate, while the hot melt system ensures the uniformity and adhesion of the glue coating by controlling temperature and pressure.

1.2 Selection and performance requirements of hot melt adhesive

The choice of glass fiber hot melt adhesive directly affects the coating effect and product performance. Common hot melt adhesives include hot melt vinyl, polyurethane, etc., and their properties include viscosity, fluidity, curing time, etc. When selecting hot melt adhesive, you need to consider the characteristics of the base material and the use environment to ensure that the product after adhesive coating meets relevant standards and requirements.

1.3 Working principle of glass fiber hot melt adhesive coating machine

The working principle of the fiberglass hot melt adhesive coating machine is to heat the hot melt adhesive to a liquid state, and then evenly coat the hot melt adhesive on the glass fiber substrate through the coating system. In this process, the control system plays a key role in ensuring that the temperature, pressure and coating speed of the melt are within the appropriate range.

Part 2: How to do it

2.1 Equipment preparation

Before operating the fiberglass hot melt adhesive coating machine, you first need to prepare the equipment. Including checking the status of coating system, hot melt system and control system to ensure that the equipment is in normal working condition. At the same time, the hot melt adhesive is inspected to confirm that the type and quality of the melt adhesive meet the requirements.

2.2 Temperature and pressure regulation

After starting the equipment, the temperature and pressure of the hot melt system need to be adjusted. The appropriate temperature is set by the control system to ensure that the hot melt adhesive can reach a liquid state, and the pressure is adjusted to ensure that the melt adhesive can flow evenly during the coating process.

2.3 Coating speed control

Coating speed is one of the key factors affecting coating quality. The coating speed is adjusted through the control system to adapt to different substrates and coating requirements. During the coating process, attention needs to be paid to maintaining a stable coating speed to ensure a uniform thickness of the coating layer.

2.4 Cleaning and maintenance

Regular cleaning and maintenance are key to maintaining long-term stable operation of the fiberglass hot melt adhesive coating machine. Clean the coating system, hot melt system and nozzles to prevent residues from affecting the coating effect. At the same time, regularly check various parts of the equipment and promptly replace seriously worn parts to extend the service life of the equipment.

Part 3: Technical Requirements

3.1 Environmental requirements

The glass fiber hot melt adhesive coating machine needs to maintain a relatively stable ambient temperature and humidity during use to ensure the stability of the coating effect. In special circumstances, corresponding measures may need to be taken, such as installing constant temperature and humidity equipment.

3.2 Operator training

Personnel who operate glass fiber hot melt adhesive coating machines need to receive professional training and understand the basic principles, operating methods and maintenance points of the equipment. Master operating skills proficiently, improve the operator's adaptability, and ensure the normal operation of the equipment.

3.3 Quality control

During the production process, a complete quality control system needs to be established to detect and evaluate coated products. By establishing quality control standards, problems in production are discovered and corrected in a timely manner to ensure that coated products meet customer requirements.

Conclusion

As an advanced coating equipment, glass fiber hot melt adhesive coating machine has wide application prospects in construction, automobile, aerospace and other fields. By having an in-depth understanding of its technical principles, operating methods and technical requirements, we can better leverage its advantages, improve production efficiency, ensure product quality, and meet market demand. We hope that the introduction in this article can provide useful reference for related industries.