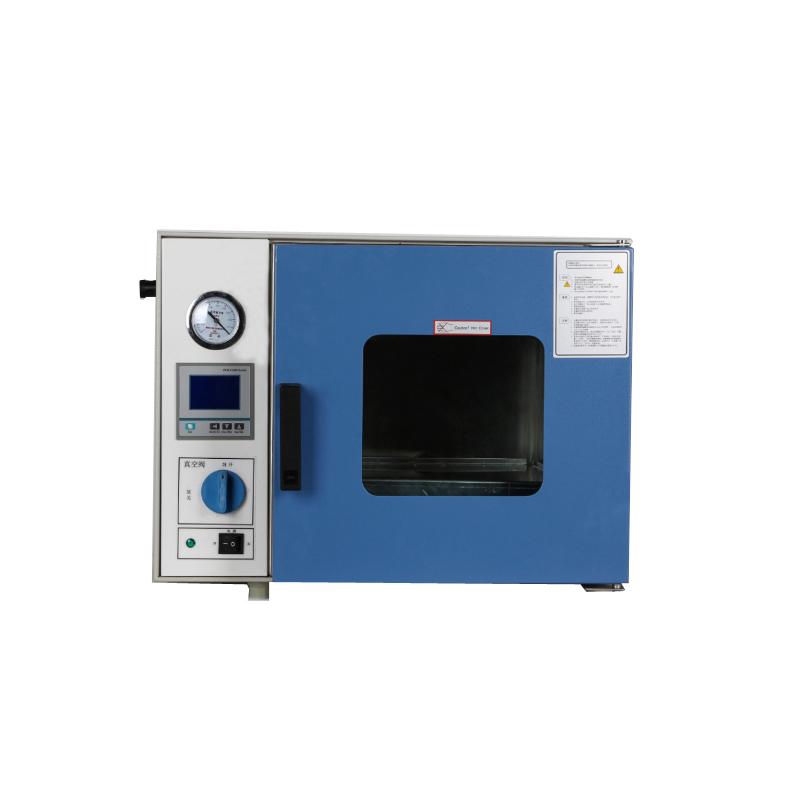

In fields such as scientific experiments, medical care, and pharmaceutical industries, drying samples is a very important step. As an efficient and precise drying equipment, the electric thermostatic vacuum Drying Oven is widely used in various fields to protect the quality and stability of samples. This article will deeply explore the principle, function, application scope and importance of electric thermostatic vacuum Drying Oven in experiments and production.

Fundamental

The electric thermostatic vacuum drying box has a built-in electric heater. The heat generated by the heater increases the air temperature in the box to the set drying temperature. The vacuum system can extract the air from the box to form a low-pressure environment and promote the evaporation of water on the surface of the sample. The electric thermostatic vacuum Drying Oven is equipped with a precise constant temperature control system, which can keep the temperature inside the oven stable near the set value according to the parameters set by the user.

Through the synergistic effect of electric heating and vacuum systems, the water on the sample surface can be evaporated quickly and efficiently. It has a precise constant temperature control system, which can keep the temperature inside the box stable at the set value and avoid affecting the drying effect of the sample due to temperature fluctuations. The vacuum system can extract the air from the box to create a low-pressure environment, which helps accelerate the evaporation of water on the sample surface and ensures drying effect. Equipped with multiple safety protection functions, such as over-temperature protection, over-voltage protection, etc., to ensure the safe operation of equipment and samples.

Application scope

Electric thermostatic vacuum Drying Ovens are widely used in various fields and are mainly used for drying various samples in laboratories, such as chemical reagents, biological samples, etc. Used for drying medical devices, pharmaceuticals, etc. to ensure product quality and stability. Used for drying processing in the pharmaceutical manufacturing process, such as drying tablets, capsules, etc. Used for drying in food processing, such as vegetables, fruits, etc. Used for drying electronic components to ensure stable product quality and performance.

Through precise temperature control and vacuum drying technology, the quality and stability of sample drying are guaranteed. The electric constant temperature vacuum Drying Oven can dry quickly and efficiently, improving work efficiency. By improving product quality and work efficiency, production costs are saved and economic benefits are improved. With the development of science and technology and the continuous changes in industrial needs, the electric constant temperature vacuum Drying Oven will be continuously updated and improved to meet the drying needs of various samples.

In general, as an efficient and precise drying equipment plays an irreplaceable role in protecting sample quality and improving work efficiency. With the continuous advancement of science and technology and the increasing industrial demand, its application prospects in various fields will be broader.