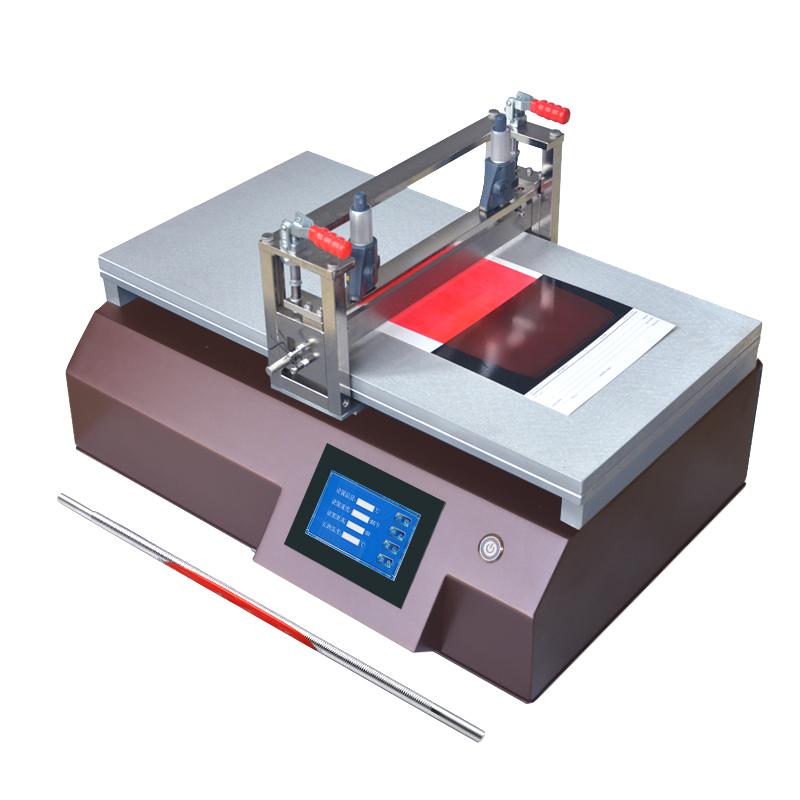

The wide application of phosphors has penetrated into various industries, from logos to decoration, and its unique fluorescent effect makes it popular in the market. However, in order to protect the durability and stability of phosphors on product surfaces, an effective coating method is required. As an efficient and precise coating equipment, the automatic film coating machine has shown great potential in the application of phosphors.

First, the automatic coating machine ensures uniform coating of phosphor through its precise control system. Uniform distribution of phosphor is critical to produce consistent fluorescence effects. Traditional coating methods may cause uneven spots or areas of phosphor on the product surface, affecting the appearance and quality of the product. The automatic coating machine can accurately control the spray volume and coverage of fluorescent powder according to the set parameters, ensuring that each product surface obtains a uniform fluorescent effect.

Secondly, the efficient production capacity of the automatic film coating machine is suitable for large-scale production environments. Where large quantities of phosphors need to be applied, traditional manual application methods can be inefficient and error-prone. The automatic film coating machine can achieve continuous and stable production, greatly improving production efficiency and reducing labor costs. This is especially important for companies that need to produce fluorescent products in large quantities.

In addition, automatic Film Applicators are able to maintain environmental friendliness during the coating process. It can minimize the waste of phosphor through precise spray control and reduce the impact on the environment. At the same time, automatic film coating machines usually use advanced technology and materials, have a high energy efficiency ratio, and reduce energy consumption and waste generation.

In summary, the application of automatic coating machines in phosphor coating has significant advantages, including precise coating control, efficient production capacity and environmental protection. As the market for fluorescent products continues to grow, automatic coating machines will become an indispensable production tool for manufacturers, helping them achieve high-quality and efficient manufacturing of fluorescent products.