Automatic coating machine (ATM) technology has been increasingly used in modern industry, and its efficient and precise coating capabilities have brought great convenience to various application fields. In the field of materials science, the application of automatic coating machines has also received widespread attention, especially in the preparation of self-healing materials. This article will focus on the use of automated coaters in preparing self-healing acrylic coatings.

Self-healing materials are a type of material with self-healing capabilities that can automatically repair themselves after damage, thereby extending the service life of the material and reducing maintenance costs. Acrylic coating is a commonly used coating material with excellent weather resistance and chemical stability. It is widely used in aerospace, automobile manufacturing, construction and other fields. However, once the traditional acrylic coating is damaged, it often requires manual repair, which is time-consuming, labor-intensive and costly. Therefore, developing an acrylic coating with self-healing function is of great significance to improve the performance of the coating.

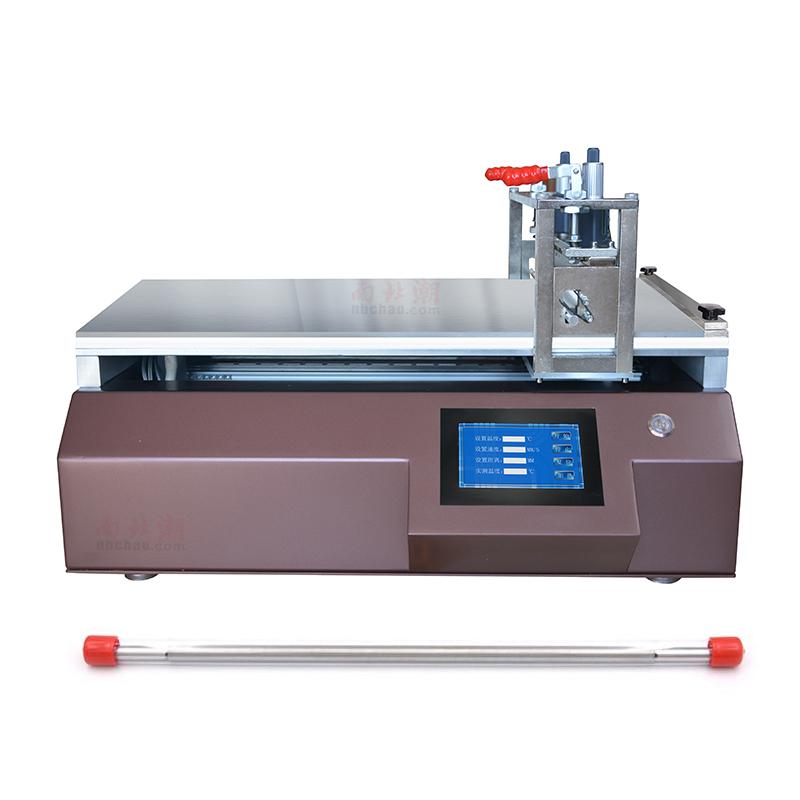

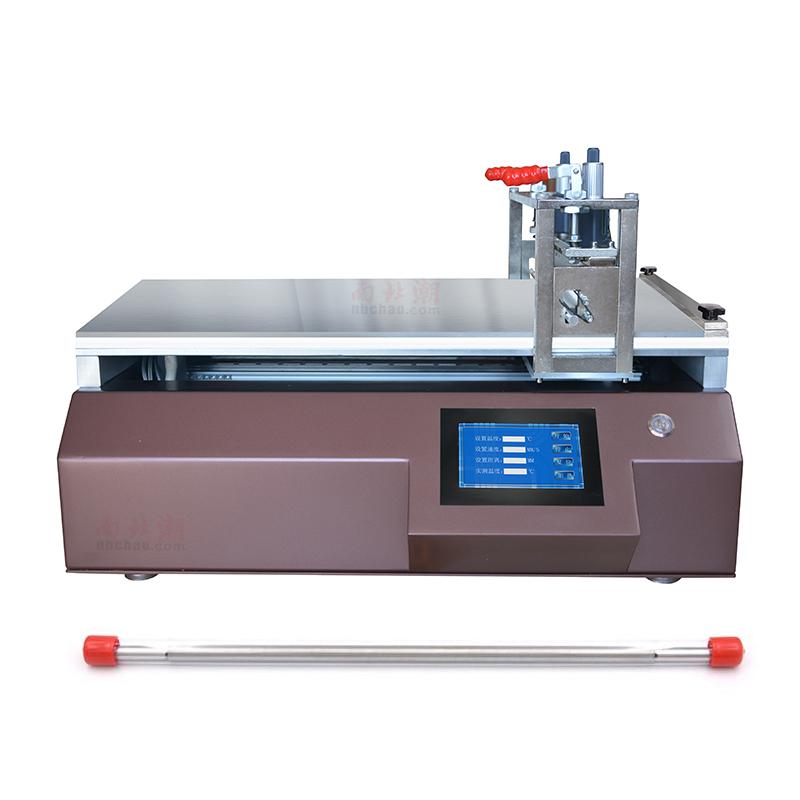

Automatic coating machine technology can achieve precise control of key properties such as coating thickness and uniformity by accurately controlling coating parameters and coating processes, providing technical support for the preparation of self-healing acrylic coatings. First, a self-healing microcapsule system such as microcapsules or microgel droplets is added to the acrylic paint, and an automatic coating machine is used to evenly coat it on the surface of the substrate. These microcapsules contain a repair agent inside. When the coating is damaged, the microcapsules will burst and release the repair agent, which reacts with the catalyst in the external environment to achieve self-repair of the coating.

Secondly, automatic coater technology can also achieve precise control of the thickness and morphology of self-healing acrylic coatings. By adjusting parameters such as the coating speed and nozzle spacing of the coater, precise control of the coating thickness can be achieved to ensure that the release amount of the repair agent is within an appropriate range. At the same time, the automatic coating machine can also use a multi-head nozzle system to achieve multi-level, multi-functional coating, further improving the performance and functionality of the coating.

The specific preparation methods and requirements are introduced in detail in the research paper "Preparation and Anti-corrosion Application of Water-Induced Self-Healing Composite Coatings".

Materials and methods

1. Materials

N,N-dimethylformamide (DMF) and dichloromethane (CHâClâ), BTC, sodium molybdenum oxide (Mo) and ethanol, CuClâ·2HâO and 1H-benzotriazole (BTA), deionized water, Q235 Carbon steel (CS), commercial clear acrylic resin

2. Material preparation

2.1. Preparation of MOF-199

Dissolve CuClâ·2HâO (0.2319 g) and BTC (0.1765 g) in the mixed solvent (water:DMF:ethanol=1:1:1).

Heat to 85°C for 24 hours with vigorous stirring to form MOF-199.

MOF-199 was collected by filtration and rinsed with DMF and CHâClâ, and finally dried under vacuum.

2.2. Preparation of BTA-Mo@MOF-199

BTA (0.1 g) and Mo (0.1 g) were dispersed in ethanol.

After adding MOF-199 (0.1 g), stir vigorously for 24 hours, collect by filtration, rinse with ethanol and dry.

2.3. Preparation of self-healing acrylic coating

BTA-Mo@MOF-199 (0.1 g) and commercial acrylic paint (2 g) were dispersed in ethanol.

The mixture is coated on carbon steel using an automatic coating machine with a coating thickness of approximately 80 microns.

In order to remove the coating bubbles as much as possible, vacuum treatment was performed for 48 hours and dried at room temperature for 7 days.

3. Performance testing method

Morphology observation: Field scanning electron microscopy (FSEM, JOEL) was used to observe MOF-199 and the self-healing coating, and elemental analysis (EDS) was performed.

FTIR Spectrum: The FTIR spectrum of MOF-199 is measured in the 4000-500 cmâ»Â¹ wavelength range.

XRD analysis: XRD diffraction patterns of all samples were measured using an X-ray diffractometer (Bruker D8 ADVANCE).

Thermogravimetric analysis: Heat the sample from room temperature to 900°C in nitrogen and measure the thermogravimetric analysis curve.

Specific surface area and pore structure: Specific surface area and pore volume were determined using Nâ adsorption/desorption at liquid nitrogen temperature.

Electrochemical Impedance Spectroscopy: Electrochemical impedance spectroscopy (EIS) was performed in the frequency range from 10âµ to 10â»Â² Hz using an electrochemical station (Gamry 600).

Self-healing performance test: Conduct self-healing test in 3.5wt.% NaCl aqueous solution. In this study, an acrylic coating with self-healing properties was successfully prepared by preparing MOF-199 and BTA-Mo@MOF-199 materials. Through the application of characterization methods, the microstructure and chemical composition of the coatings were demonstrated. In the future, this kind of coating with self-healing function may have broad application prospects in the field of anti-corrosion.

In conclusion, automatic coating machines have important application prospects in preparing self-healing acrylic coatings. By precisely controlling coating parameters and coating processes, precise control of coating properties can be achieved, providing technical support for the preparation of self-healing acrylic coatings, and opening up new possibilities for improving coating performance and application fields. sex.