introduction

As demand for low-cost flat-panel lighting continues to grow, mass production technology is critical for manufacturing large-area light-emitting diodes (LEDs). However, existing manufacturing methods still have challenges in controlling film uniformity, which limits the development of organic small molecule (OLED), quantum dot (QLED), polymer (PLED), and new hybrid perovskite (PELED) LEDs. application. In this article, we introduce the application of low-temperature drawdown blade coating technology in the preparation of methylammonium lead iodide (MAPbI3) perovskite thin films, using a sol-gel engineering approach to overcome the challenges in thin film preparation.

method

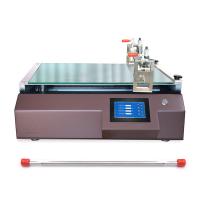

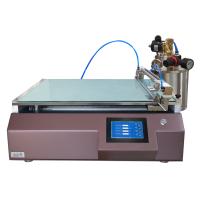

By using a dilute, organic ammonium-excess precursor, combined with a drawdown blade coating technique, the efficient preparation of perovskite films was achieved at a low temperature of 50 °C . First, select the MAPbI3 precursor and control its concentration in the range of 0.02 to 0.8 M. Then, during the blade coating process, the film morphology is ensured to be optimized by optimizing parameters such as coating speed, temperature, and nitrogen (N2) knife pressure. At the same time, a nitrogen (N2) knife was added to accelerate the evaporation of the solvent and further improve the morphology of the film. Through these methods, we achieved precise control of perovskite films, resulting in large-area films with extremely low roughness.

result

The prepared perovskite film has extremely low roughness reaching 1 nm over a large area (54 cm2). At the same time, the performance of the PeLED prepared by blade coating was evaluated, and it was found that its external quantum efficiency (EQE) reached 16.1%, which was higher than the LED performance under other preparation methods. This demonstrates the potential application of drawdown blade coating technology in preparing perovskite LEDs.

discuss

By optimizing the blade coating process, an efficient perovskite LED film was prepared. This low-temperature blade coating technology not only achieves film uniformity and precise control, but also has the advantages of high throughput and low cost, providing a new solution for mass production of high-efficiency LEDs. The success of this work highlights the potential application of blade coating technology in LED manufacturing and provides new possibilities for the development of flat-panel lighting and displays.