As a key industrial equipment, polymer sheet coating machine plays an important role in modern production. It is capable of coating polymer materials on the surface of substrates, providing coating protection, reinforcement and decoration for various industries. This article will deeply discuss the technical principles, key components, coating processes, applications and future development trends of polymer sheet coating machines.

1. Overview of polymer sheet coating machine

Polymer sheet coating machine is a kind of equipment used to evenly coat polymer materials on the surface of substrates. According to the different coating methods, it can be divided into dry coater and wet coater. Dry coaters cure the coating by spraying it evenly on the surface of the substrate and then drying it, while wet coaters immerse the substrate in the coating process and then extrude the excess paint through calendering or extrusion to form a uniform coating.

2. The key components of the polymer sheet coating machine

Coating mechanism: The coating mechanism is the core component of the polymer sheet coating machine, including the coating head, coating roller, etc. The applicator head sprays, squeezes or rolls the paint evenly across the surface of the substrate, while the applicator roller rotates to flatten the paint to ensure an even application.

Control system: The control system is responsible for adjusting the coating speed, thickness and other parameters to ensure the stable coating quality. Through sensors and feedback systems, the parameters of the coating process are monitored in real time, and the coating machine is automatically adjusted to improve production efficiency and product quality.

3. Coating process

Preparation: A series of preparations are required prior to coating. The first is the substrate surface treatment, which includes cleaning, sanding, primer coating, etc., to ensure adhesion and surface flatness after coating. The second is the formulation of coatings, which requires the selection of appropriate coating types and formulations according to coating requirements.

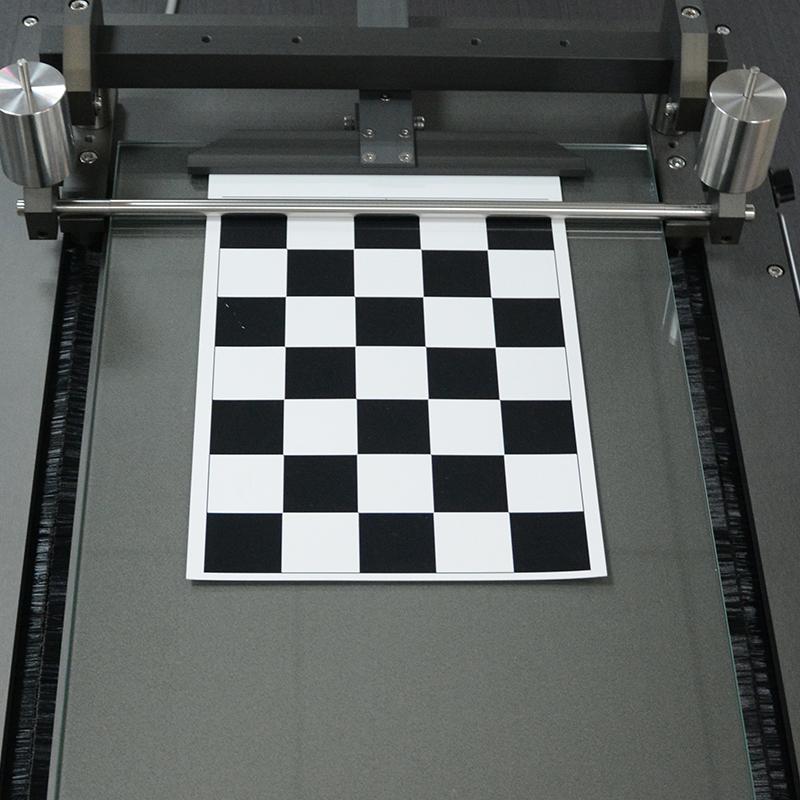

Coating process: During the coating process, parameters such as coating speed, thickness and temperature need to be strictly controlled to ensure that the coating quality meets the requirements. In dry coating, the paint is sprayed and then dried, usually using drying or UV curing techniques. In wet coating, the coating is usually applied to the surface of the substrate by rolling or dipping, and then extruded or extruded to form a uniform coating.

Fourth, the application field of polymer sheet coating machine

Packaging industry: Polymer sheet coating machines have a wide range of applications in the packaging industry. In the field of food packaging, coating machines can be used to manufacture food packaging bags, plastic wrap, etc., to improve the waterproofness and freshness of packaging materials. In the field of pharmaceutical packaging, coating machines can be used to manufacture pharmaceutical packaging bags, medical tapes, etc., to ensure the safety and quality of drugs.

Building Materials: In the field of building materials, polymer sheet coating machines are widely used in the manufacture of waterproof materials, thermal insulation materials, etc. The coating machine can evenly coat the polymer coating on the surface of the building material, improve its waterproof performance and weather resistance, and prolong the service life.

Electronics industry: In the electronics industry, polymer sheet coaters are used to manufacture thermally conductive materials, battery separators, etc. At the same time, the coater can also coat the battery separator between the positive and negative electrodes of the battery to prevent the battery from short circuit and improve the safety of the battery.

conclusion

Polymer sheet coating machine has become an indispensable part of modern industrial production with its wide application in various fields and the potential for technological innovation. Strengthening relevant research and technological innovation and improving the performance and stability of the coating machine will promote its further application and development in various fields and promote the high-quality development of industrial production.