introduction

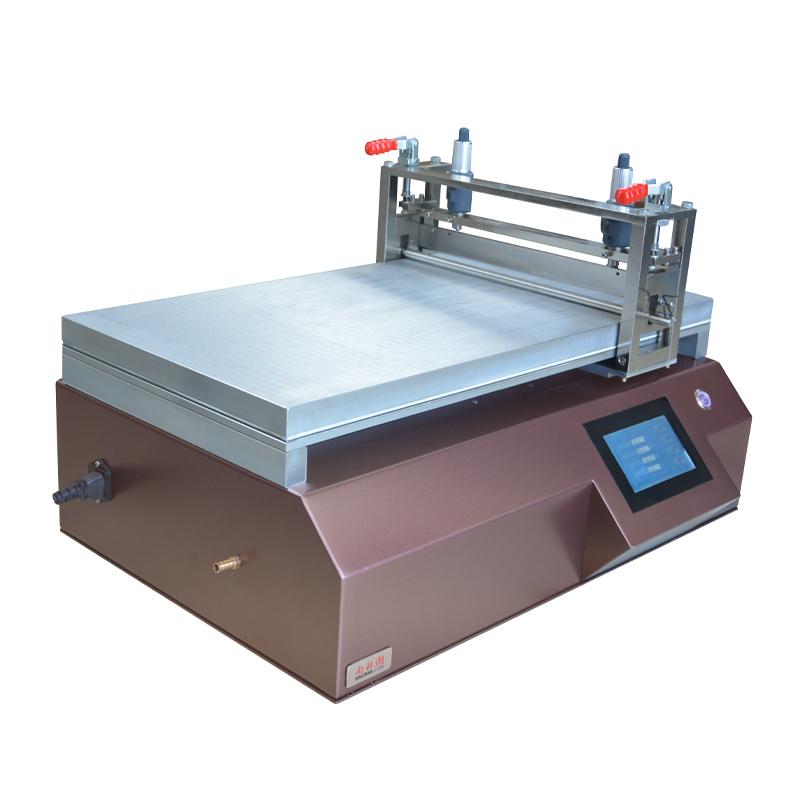

In modern industrial production, coating technology is a crucial process, which is widely used in the surface treatment and coating of various materials. Small coaters play an important role in achieving efficient and precise coating. This article will discuss the application of small coaters in polyimide epoxy adhesives, including principles, operation and sizing.

Introduction to polyimide and epoxy adhesives

Polyimide

Polyimide is a high-performance polymer with excellent thermal, mechanical, and chemical stability. Due to its special molecular structure, polyimide is often used in engineering applications at high temperatures, high pressures, and in corrosive environments, such as aerospace, electronics, automotive, and other fields.

Epoxy glue

Epoxy adhesive is a common structural adhesive that consists of an epoxy resin and a curing agent. It has excellent adhesion, chemical resistance and mechanical properties, and is widely used in bonding, sealing and coating fields.

principle

In the process of coating epoxy adhesive with polyimide, the epoxy adhesive is evenly coated on the surface of the polyimide substrate mainly through the coating roller. Here's how it worksBy adjusting the gap between the coating rollers, the coating thickness of the epoxy adhesive is controlled. A smaller gap allows for a thinner coating, while a larger gap allows for a thicker coating.By adjusting the operating speed of the coater, the coating speed of epoxy adhesive on the surface of the substrate is controlled. Faster coating speeds increase productivity but may reduce coating quality, while slower coating speeds result in higher coating quality but reduce productivity.Through the design of the coating roller and the heating system, the uniform coating of epoxy adhesive on the surface of the substrate is ensured. Uniform application ensures the quality and performance of the coating.

operate

When the small coater is applying polyimide epoxy adhesive, the following operations need to be performed:

Clean the coating rollers and surfaces of the coater to ensure that there are no impurities and contaminants. Check whether the parameters and equipment of the coating machine are normal.

According to the coating requirements, adjust the gap of the coating roller and the coating speed. In general, the appropriate coating thickness and speed are determined according to the nature and requirements of polyimide and epoxy adhesives.

Start the coater and adjust the running speed to the set value. Ensure that the heating system of the coating roller is working properly to ensure the uniformity of the epoxy adhesive application.

The polyimide substrate is fed into the coater, and the epoxy adhesive is evenly applied to the surface of the substrate by means of a coating roller. Ensure that the position and operation of the substrate are stable during the coating process.

Regularly check the coating quality to ensure that the coating thickness and uniformity meet the requirements. Adjust the coating parameters as needed to ensure the best coating results.

After the coating task is completed, stop the operation of the coater and carry out cleaning and maintenance work on the coater and coating roller.

lectotype

When choosing a small coater suitable for coating polyimide epoxy adhesives, the following factors need to be considered:

The coating width of the coater is determined according to the coating requirements. Typically, a coater that is slightly larger than the width of the substrate is selected to ensure the coverage of the coating.

Consider the range of coating thicknesses that the coater can achieve to meet different coating requirements. Choosing a coater with a wide range of coating thicknesses allows for more flexibility in adapting to different application scenarios.

Pay attention to the coating thickness and speed control accuracy of the coating machine to ensure the stability and consistency of the coating quality.

Choosing a coater that is easy to operate and easy to maintain can reduce operating costs and increase productivity.

Comprehensively consider factors such as the price, performance and brand reputation of the coating machine, and choose a cost-effective coating machine.

conclusion

Small coaters are of great significance in the application of polyimide epoxy adhesives, which can achieve efficient and precise coating processes, and provide reliable technical support for various industrial production. When selecting and operating the coating machine, it is necessary to make reasonable selection and adjustment according to the specific coating requirements and production conditions to ensure the coating effect and production efficiency.