Summary

Choosing a glue applicator that fits your needs is essential for production in the resin industry. This article will deeply discuss the selection technology of gluing machine on resin, including the consideration of gluing machine type, performance parameters, application range, etc., to help you better choose the right gluing machine equipment.

Introduction

As an important coating equipment, gluing machine is widely used in the production and processing of resin materials. However, it is not easy to choose the one that suits your needs among the many gluing machine models. This article will introduce the selection technology of the gluing machine on the resin in detail, help you understand the performance parameters and application scope of the gluing machine, and provide guidance for the correct selection of the gluing machine.

The type of gluing machine

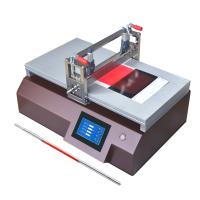

Roller coater: A roller coater is a common type of gluing machine that evenly applies the coating agent to the substrate by means of rollers. It is suitable for coating film-like resin materials, such as resin films, paper, etc.

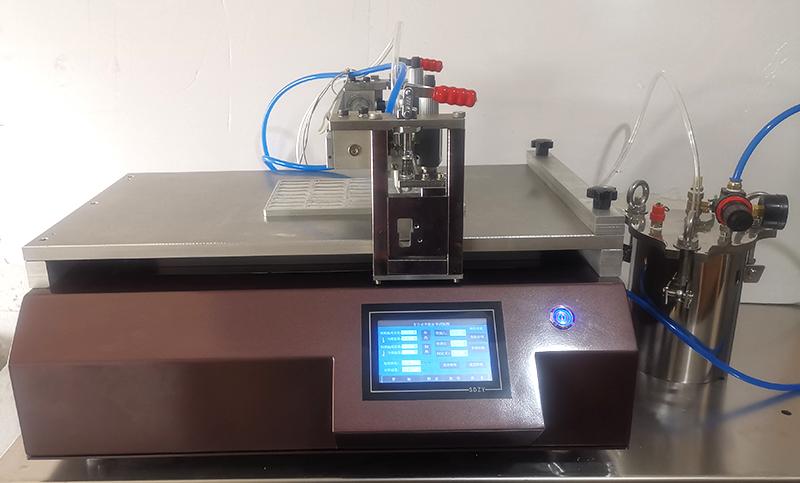

Spraying machine: The spraying machine uses a nozzle to spray the coating agent on the substrate, which is suitable for coating resin materials with high coating requirements, such as automobile painting, paint coating, etc.

Brush coating machine: The brush coating machine applies the coating agent to the substrate through the brush, which is suitable for resin materials that do not have high requirements for coating thickness and quality, such as furniture surface coating.

Performance parameter selection

Coating width: Determine the coating width of the gluing machine according to the production needs to ensure that the coating range covers the required area.

Coating speed: Determine the coating speed of the gluing machine according to the production efficiency requirements to ensure the balance between production efficiency and coating quality.

Coating thickness control: Choose a gluing machine with precision coating thickness control to ensure the stability and consistency of coating thickness.

Equipment stability: Considering the equipment stability and reliability of the gluing machine, choose the brand and model with good quality and stability.

The scope of application considerations

Material type: Select the appropriate gluing machine model according to the type of resin material to be coated to ensure the coating effect and quality.

Production environment: Considering the production environment conditions, select the appropriate type and specification of the gluing machine to ensure that the equipment can operate stably at the production site.

Process requirements: Choose the gluing machine according to the requirements of the coating process to ensure that the coating process meets the production requirements and standards.

Frequently Asked Questions

What should I do if the coating thickness is uneven?A: Choose a gluing machine with coating thickness control function, and adjust the coating parameters according to the actual situation.

A: Too fast application speed may lead to a decrease in coating quality, so it is necessary to adjust the coating speed according to the actual situation.

Answer: Regularly clean, lubricate and maintain the gluing machine to ensure the normal operation and service life of the equipment.

Conclusions

The right choice of gluing machine is essential for the production of resin materials. Through the introduction of this article, you should have a deeper understanding of the selection technology of the gluing machine on the resin. When choosing a gluing machine, please consider the type, performance parameters and application range of the gluing machine according to your own needs and actual conditions, and choose a gluing machine equipment with stable performance and strong applicability.