Introduction

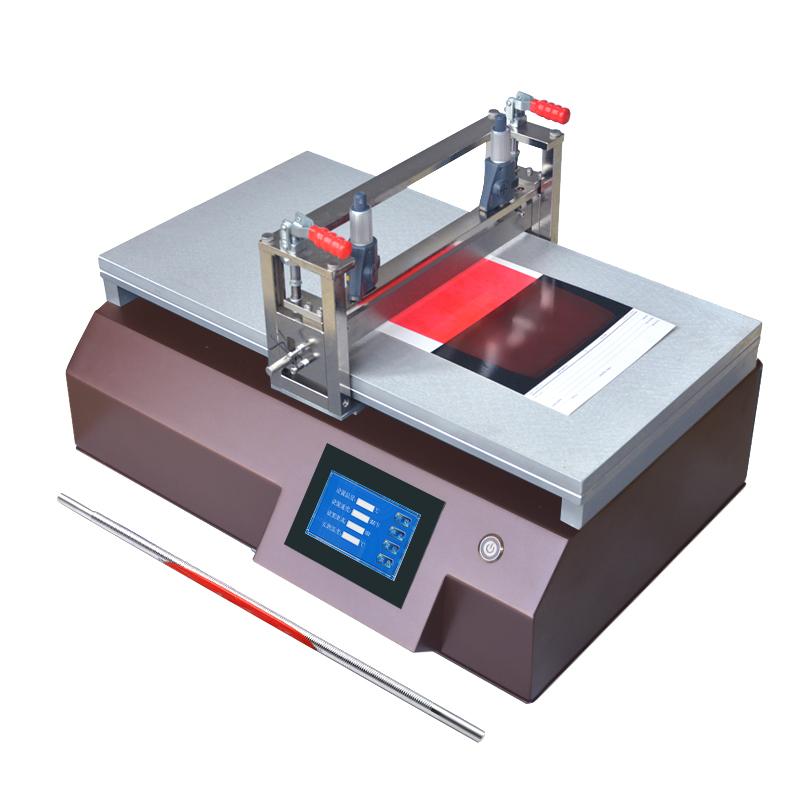

As a portable and efficient coating equipment, small coaters are widely used in laboratory and small-scale production scenarios. As an important coating, epoxy polyester has excellent chemical, abrasion and corrosion resistance, and is suitable for a variety of application scenarios. The purpose of this experiment was to investigate the coating effect and application potential of epoxy polyester applied to film by a small coater.

Experimental materials and equipment

1. Experimental Materials:Epoxy polyester coatings,Thin film substrates

Experimental equipment:

Small Coating Machine,Drying oven,Weighing Instruments,Light microscopy

Experimental procedures

1. Preparation:

The film substrate is fixed on the table of a small coater to ensure that the surface of the substrate is clean and flat.

By adjusting the differentiator, the gap between the adjustable scraper and the bottom plate is set to adjust the appropriate coating film thickness.

2. Coating Experiment:

Start the coater and set the coating parameters, such as coating speed, paint thickness, etc.

Apply the epoxy polyester material to the front of the substrate and click Start Run to start applying.

Observe the uniformity and coverage of the coating during the coating process, and adjust the coating parameters to obtain a good coating effect.

After the coating is complete, the coated film substrate is removed and placed in a Drying Oven for curing.

3. Detection and Analysis:

Use an optical microscope to observe the surface topography and coating thickness of the coated film.

The quality of the coated film is inspected using a weighing instrument, and the thickness and coating rate of the coated film are calculated.

Performance tests are performed on coated films, such as chemical resistance, abrasion resistance, etc.

Experimental results and discussion

After experimental testing, the following results were obtained:

Good application results: The small coater is able to evenly coat the epoxy polyester coating on the polyester-based film substrate to form a flat, uniform coating.

Precise coating thickness control: After adjusting the coating parameters of the coating machine, the coating thickness can be accurately controlled to ensure that the thickness of the coated film meets the requirements.

Stable quality of coated film: The quality stability of the coated film is high, the coating surface is smooth, and there is no obvious coating sagging or bubble phenomenon.

High coating rate: After weighing instrument testing, the coating rate of the coated film is high, and the expected coating effect is achieved.

Conclusions and prospects

In this experiment, epoxy polyester paint was applied to the film with a small coater, and a good coating effect was obtained. The small coater has the advantages of high coating efficiency and precise coating thickness control, and has a wide range of application potential in the field of film coating. In the future, the effect of small coaters on different coatings and substrates can be further explored