Concrete admixtures occupy an important position in modern concrete technology, and the determination of their solid content is the key link to ensure their performance stability. In this paper, three commonly used solid content determination methods are introduced in detail with reference to the GB/T 8077-2023 homogeneity test method for concrete admixtures to be implemented on June 1, 2024: drying method, dilution drying method and vacuum drying method.

1. Drying method

principle

At a temperature of 100°C~105°C, the water is evaporated by drying, so as to achieve the purpose of drying.

instrument

Balance: 0.0001g index

Drying oven: The temperature range is room temperature ~ 200°C

Weighing flasks with caps

Dryer: Filled with color-changing silica gel

Test procedure

Put the clean weighing flask with cap into the Drying Oven, bake at 100°C~105°C for 30min, take it out and put it in the dryer, cool it for at least 30min and weigh it, repeat the above steps until the quantity is constant, and its mass is m0. Weigh about 5g of the sample in the weighing flask with a constant amount to the accuracy of 0.0001g, and weigh the total mass of the liquid sample and the weighing flask as m. Put the weighing flask containing the liquid sample into the Drying Oven, open the cap, raise the temperature to 100 °C ~ 105 °C to dry, cover the lid and place it in the dryer to cool for at least 30min before weighing, repeat the above steps until the amount is constant, and its mass is m2.

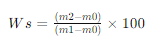

The solid content w is calculated according to equation (2):

Thereinto:

Ws: solid content

m2: the mass of the specimen after weighing flask and drying, in grams (g)

m0: the mass of the weighing flask in grams (g)

m1: the mass of the weighing flask plus the specimen in grams (g)

2. Dilution and drying method

principle

Put the diluted test sample in a constant amount of Petri dish and bake it at a certain temperature to a constant amount. Test the quality of the specimen before and after drying.

instrument

Balance: 0.0001g index

Drying oven: The temperature range is room temperature ~ 200°C

Weighing flasks with caps

Dryer: Filled with color-changing silica gel

Test procedure

Put the clean weighing flask with cap into the Drying Oven, bake at 100°C~105°C for 30min, take it out and put it in the dryer, cool it for at least 30min and weigh it, repeat the above steps until the quantity is constant, and its mass is m0. Dilute the tested sample: Shake the tested sample thoroughly, take the tested sample with a small spoon and accurately weigh W (8.0000g10.0000g) and place it in a beaker. Add distilled water W: (30.000g50.0000g) to dilute the sample. Fully stir and evenly dilute the tested sample, take about 5g of the diluted tested sample with a small spoon, accurate to 0.0001g, put it into the weighing flask that has a constant amount, close the cap, and accurately weigh the total mass of the sample and the weighing flask as m1. Put the weighing flask containing the sample into the Drying Oven, open the weighing bottle cap, raise the temperature to 100 °C ~ 105 °C to dry, cover the lid and place it in the dryer to cool for at least 30min before weighing, repeat the above steps until the quantity is constant, and its mass is m2.

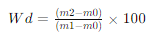

The solid content of the diluted specimen is calculated according to Eq. (3):

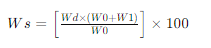

The solid content of the sample is calculated according to equation (4):

Thereinto:

Wd: The solid content of the diluted sample

m2: the mass of the specimen after weighing flask and drying, in grams (g)

m0: the mass of the weighing flask in grams (g)

m1: the mass of the weighing flask plus the specimen in grams (g)

W0: Specimen mass in grams (g)

W1: Mass of distilled water in grams (g)

The same specimen must be tested three times, and its arithmetic mean is taken. When the difference between the maximum or minimum value and the median value exceeds 10%, the maximum or minimum value is removed and the average value of the other two values is taken. When the difference between the maximum and minimum values and the median value is more than 10%, the test is invalidated.

Vacuum drying method

principle

By reducing the air pressure at the time of drying, the boiling point of the water is lowered, so that the water is dried at a lower temperature.

instrument

Balance: 0.0001g index

Vacuum Drying Oven: the temperature range is room temperature ~ 200°C, and the vacuum degree is less than 0.133 kPa

Weighing flasks with caps

Dryer: Filled with color-changing silica gel

Test procedure

Put the clean weighing flask with cap into the vacuum Drying Oven, bake at 75 °C ~ 80 °C for 30min, take it out and put it in the dryer, cool it for at least 30min and weigh it, repeat the above steps until the quantity is constant, and its mass is m0.Weigh about 5g of sample in a weighing flask with constant weight, accurate to 0.0001g, and weigh the total mass of the liquid sample and weighing flask mPut the weighing flask containing the liquid sample into the vacuum Drying Oven, open the cap, raise the temperature to 75 °C ~ 80 °C, turn on the Vacuum Pump, vacuum to the vacuum degree ≤ 32.5 kPa, bake for at least 2h, cover the lid and put it in the dryer to cool for at least 30min before weighing, repeat the above steps until the amount is constant, and its mass is m2.

The calculation of the solids content is carried out according to 1.4.

The limit of repeatability is 0.30% and the limit of reproducibility is 0.50%.

In this paper, three commonly used methods for determining the solid content of concrete admixtures are described in detail: the drying method, the dilution drying method, and the vacuum drying method. Each method has its own unique principles, instruments and test steps, and the most suitable method can be selected according to the actual needs for the determination of solid content to ensure the quality and performance stability of concrete admixtures.