summary

As a common plastic film material, PET film has a wide range of applications in packaging, printing, electronics and other fields. As an important adhesive, pressure-sensitive adhesive plays a key role in labels, tapes, stickers and other products. In this paper, the process and performance of automatic film coater for coating pressure-sensitive adhesive on PET film were studied. The influence of different process parameters on the coating effect was verified by experiments, and its feasibility and advantages in practical application were analyzed.

1. Introduction

PET film has excellent mechanical properties, chemical stability and transparency, and is an important packaging material and printing substrate. As a special adhesive, pressure-sensitive adhesive has the property of rapid adhesion even under slight pressure, and is widely used in labels, tapes, stickers and other products. By applying pressure-sensitive adhesive to the surface of PET film, it is possible to prepare adhesive materials with good adhesion and weather resistance. The purpose of this paper is to study the process and performance of automatic film coating machine for coating pressure-sensitive adhesive on PET film, and to provide a reference for its application in industrial production.

2. Design of Experiments

2.1 Preparation of Materials

- PET film: Common PET film is used as the base material, and the specification is 100μm thickness.

- Pressure-sensitive adhesives: Commercially available pressure-sensitive adhesives are selected, which have good adhesion and weather resistance.

2.2 Experimental equipment

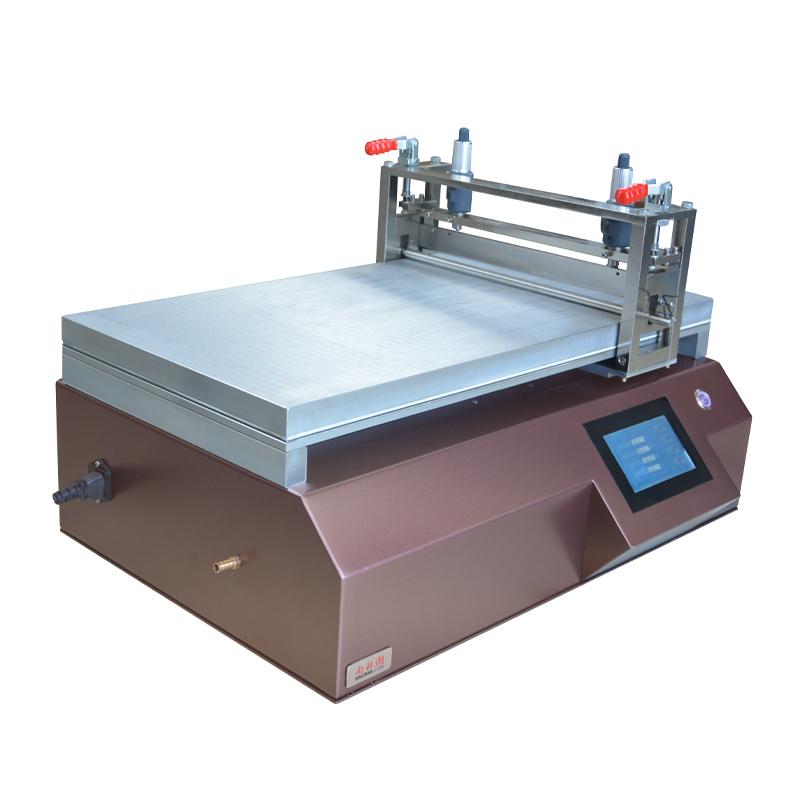

- Automatic film coating machine: An automatic film coating machine with components such as a coating head, feeding system, and drying device is used to coat the surface of PET film with pressure-sensitive adhesive.

- Visual inspection equipment: used to evaluate the appearance quality of the coated film.

2.3 Experimental Procedure

1. Set coating parameters: adjust the coating speed, pressure, temperature and other parameters of the automatic coating machine.

2. Prepare the coating solution: dissolve the pressure-sensitive adhesive in an appropriate amount of solvent to form the coating solution.

3. Coating test: The PET film is passed through the automatic film coating machine and the pressure-sensitive adhesive solution is coated.

4. Drying: Put the coated PET film into the drying device to dry and solidify.

5. Appearance inspection: Conduct visual inspection on the coated PET film to evaluate the coating effect.

3. Results and Discussion

Through experiments, it is found that the effect of automatic film coating machine on PET film is affected by many factors, including coating speed, coating thickness, pressure, etc. In terms of coating speed, a lower speed can improve the uniformity and adhesion of the coating, but reduce the production efficiency, while a higher speed can do the opposite. In terms of coating thickness, a moderate thickness can ensure the adhesion and weather resistance of the coating layer, but an excessively thick coating layer may affect the transparency and flexibility of the PET film. Therefore, in actual production, it is necessary to make reasonable adjustments according to specific requirements.

In addition, it is also necessary to pay attention to the formulation of the coating solution and the conditions of drying to ensure that the coated PET film has good performance. For different application scenarios, the coated PET film can also be subsequently processed, such as cutting, printing, etc., to meet the needs of different customers.

4. Application prospects

The automatic film coating machine has a broad application prospect for coating pressure-sensitive adhesive on PET film. It can be used to produce all kinds of labels, tapes, stickers and other products to meet the needs of different industries. With the continuous advancement of technology, the performance and stability of the automatic film coating machine will be further improved, bringing more development opportunities for the PET film processing industry.

5. Conclusion

In this paper, the process and performance of an automatic film coater for coating pressure-sensitive adhesive on PET film were studied. The influence of different process parameters on the coating effect was verified by experiments, and its feasibility and advantages in practical application were analyzed. Automatic film coating machine is of great significance in the PET film processing industry, which will provide a more efficient and stable solution for the production of related products.