summary

The purpose of this experiment was to investigate the technology of coating filter membrane on glass plates by an automatic Film Applicator. Through the design of the experimental scheme, the working principle and coating process parameters of the automatic film coating machine were optimized, so as to achieve the purpose of uniformly coating the filter film on the surface of the glass plate. The experimental results show that under the appropriate process parameters, the automatic film coating machine can efficiently and accurately coat the filter film on the glass plate, which provides reliable technical support for the production of glass products.

1. Introduction

Filter membrane is a widely used functional material, which is widely used in electronic products, medical devices, biological experiments and other fields. In these applications, the quality of the membrane has a direct impact on the performance and longevity of the product. Therefore, how to evenly and efficiently coat the filter membrane on the substrate material has become an important research topic.

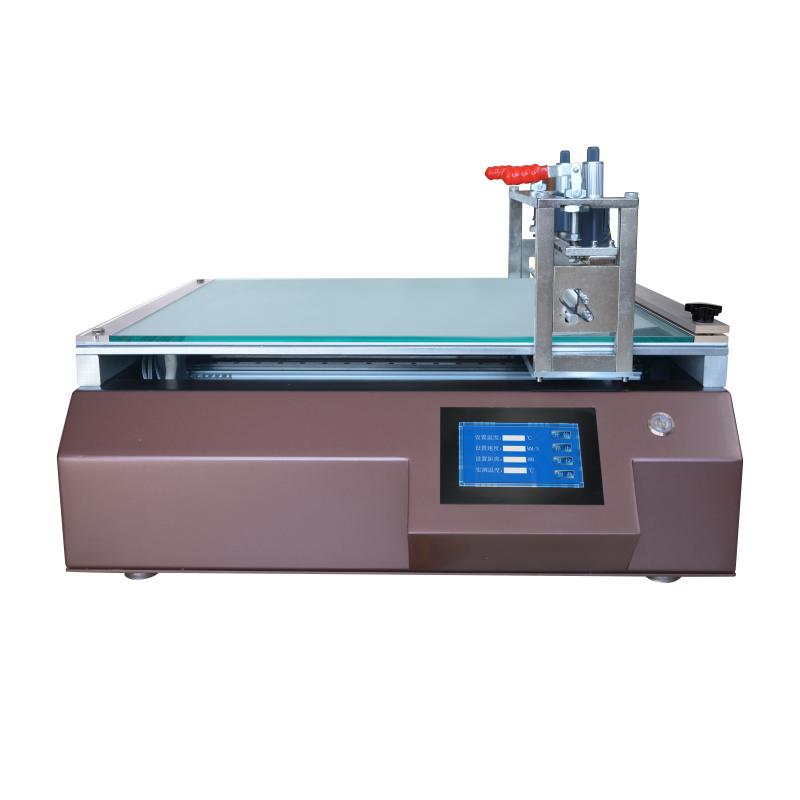

The automatic film coating machine is a kind of equipment that can realize the automation of the coating process, which has the advantages of fast coating speed and high coating uniformity. The purpose of this experiment was to use an automatic film coating machine to coat the filter membrane on the glass plate, and to control the coating quality of the filter film by optimizing the process parameters.

2. Experimental materials and methods

2.1 Experimental Materials

Glass plate: as a base material, the size is 10cm x 10cm x 0.5cm.

Filter membrane: A functional filter membrane for coating, made of polymer.

Solution: A solution used to dissolve the filter membrane, which is an organic solvent.

2.2 Experimental Methods

Preparation of solution: According to a certain formula, the filter membrane is dissolved in an organic solvent to prepare the solution required for the coating film.

Adjust the parameters of the coating machine: according to the characteristics of the filter membrane and the working principle of the coating machine, adjust the parameters of the coating machine, such as coating speed, coating thickness, etc.

Coating experiment: Place the glass plate on the workbench of the coating machine, and start the coating machine for coating experiment.

Quality inspection: The quality inspection of the coated glass plate is carried out, including the detection of coating uniformity, coating thickness and other indicators.

3. Experimental results and analysis

After a series of experiments, we obtained the experimental results of coating the filter membrane under different process parameters. When the coating speed is 1cm/s and the coating thickness is 10μm, the coating effect is better and the coating film thickness uniformity is good.

4. Conclusions and prospects

In this experiment, the coating quality of the filter film was controlled by using an automatic film coating machine to coat the filter film on the glass plate. By optimizing the process parameters, the uniformity and thickness uniformity of the coating film can be further improved. In the future, we will further study the process optimization method of the coating machine to improve the production efficiency and quality of the coating film.