Application scope and description of coating film preparation method

This method is applicable to the preparation of test panels for the determination of general properties of paint films. When preparing a coating film, the materials used for preparing the coating film, the surface treatment of the substrate, the method of making the board, the drying and state adjustment of the paint film, the constant temperature and humidity conditions, and the thickness of the paint film should be selected. This method introduces the material requirements and treatment methods of five kinds of substrates, and lists six panel making methods, which are the standard test panels and painting methods used in the general sample methods of related products.

Preparation of instruments and materials

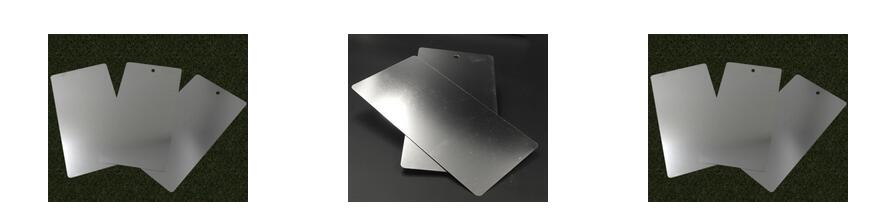

(1) The tinplate plate shall comply with the tin plating amount of E4, the hardness grade of T52, and the thickness of 0.2~0.3, nrn. Unless otherwise specified, a test plate with a size of 25mmX120tnm, 50mmX120mm or 70mmX150mm.

(2) Unless otherwise specified, the glass plate shall meet the specified technical requirements and be a test plate with a size of 90mmX120mmX(2~3)mm.

(3) Unless otherwise specified, the steel plate shall conform to the technical requirements of ordinary broken steel, and the size of the test plate shall be 50mmX120mmX(0.45~0.55)mm or 65mnX150mmX(0.45~0.55)mm.

(4) Unless otherwise specified, the aluminum plate shall meet the specified technical requirements, and the size of the test plate shall be 50mmX150nmX(1-2)mn.

(5) Asbestos-water-mixed panels Unless otherwise specified, asbestos-water-mixed panels shall meet the specified technical requirements, and the thickness of the test panels shall be 3-6mm.

(6) Steel rod Ordinary carbon steel rod, diameter (13±2), nm, length 120mm, one end is a smooth surface, and the other end has a hole

or ring.

(7) The width of the paint brush is 25~35mm.

(8) The inner diameter of the Spray Gun nozzle is 0.75~2mm.

(9) scraper

①The putty scraper is composed of a model plate and a scraper, and there are 4 wedge-shaped cards on a smooth base to compress the scraper frame and the model. The model is selected according to the atomic thickness required by the product standard.

②The paint film Applicator has various forms such as scraper type, slot rod type and wire rod type. Choose the appropriate preparer according to the rigidity and flexibility of the substrate,

(10) ViscometerApply a 4 viscometer or Iso outFlow Cup, (11) lever micrometer or other Film Thickness Gauge.

(11) The stopwatch scale is 02s,,, 13) The electric heating drum constant temperature Drying Oven.

Surface treatment of the bottom plate

Tinplate

①Clean the oil on the test panel before painting the test panel with the agent cleaning method, and use = toluene or solvent gasoline to clean the oil stains. The board can be volatilized and dried with clear agent or wiped dry with clear silk cloth. If it is not painted immediately, it should be stored in a desiccator.

② Grinding (polishing) of the legal plate If a more uniform test surface is required than that of the solvent cleaning process, it is recommended to polish the tin plate. Grinding treatment Unless otherwise specified, it should be polished with the specified 500 water sand and 111 dry grinding method.

The grinding operation procedure is as follows: a. Grind back and forth straight and evenly along the parallel direction of any side of the trial calibration; b. Grind back and forth straight and evenly in the direction perpendicular to the first direction until the original surface is worn away; e. Grind with a circular motion of 80~100mm until the circle formed on the surface is heavy.

The grinding action should be light to prevent the abrasive from being embedded in the surface, and the tin layer on the i-type board must not be completely ground off. polished

After the test plate has been cleaned, it should be cleaned according to the above-mentioned operation of "Solvent Cleaning Method".

Plate making method

Before painting, the sample is stirred evenly by a stirrer. The methods of painting and plate making include brushing, spraying, dipping, scraping, pouring and spin coating. I won't say much here.