Proper use of electronic balances

Choosing the right electronic balance needs to consider whether the weighing range and sensitivity of the balance meet your needs. The structure of the balance should be selected to adapt to the characteristics of the specific job, avoiding waste and not meeting the required accuracy.

When installing an electronic balance, it is necessary to choose a dust-proof, shock-proof, moisture-proof and constant temperature environment, and the balance should be placed on a firm bench, and the parts should be counted and cleaned. Install it correctly and correct the level, and plug it in after confirming that the power supply voltage meets the requirements.

Before you start using your electronic balance, you need to warm it up for half an hour to an hour. If used frequently, it is best to keep it on all day to ensure that a constant operating temperature is maintained inside the balance, contributing to the accuracy of the weighing process.

Electronic Balances should be calibrated regularly from the first use, and if used continuously, it is recommended to calibrate them once a week. Standard weights must be used for calibration, and the following procedures must be carried out, and the balance should be warmed up for more than 1 hour and the level should be calibrated before calibration.

When weighing operations, the control keys and function keys should be used correctly, the best integration time should be selected, and the reading and printing time should be correctly controlled to obtain the best weighing results. During the weighing process, the balance door should be closed, and the balance and door cover should be closed after use, and the power supply should be cut off and the dust cover should be covered.

The minimum weight of the balance

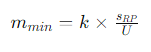

The minimum weight refers to the minimum sample size that meets the weighing requirements, and is calculated as:

Among them, k is the expansion factor (usually ≥2), s_{RP} is the standard deviation of the repeated weighing value, and U is the required weighing (such as 0.10% for "precision weighing" and 1% for "weighing" stipulated in the Chinese Pharmacopoeia).

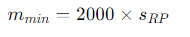

According to USP General Chapter 41, if the repeatability meets the requirements, the formula can be simplified to:

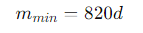

If the repeatability is less than 0.41d (d is the index value displayed), it is replaced by 0.41d and simplified to:

Occurrence and elimination of balance deviations

There are three main reasons for balance deviation. First of all, the problem of manufacturing and materials, due to the instability of materials, the influence of assembly technology and other reasons, the proportion of the balance arm can not meet the strict requirements. The second is the difference in ambient temperature, and the uneven heating of the two arms of the balance leads to a change in the arm ratio. Finally, when adjusting the balance to eat offline, the adjustment of the lifting edge knife may cause arm difference.

Variability of the balance indication

The main reasons for the variability of the balance indication include the three-tool condition, the beam components and environmental factors. The problems of the three knife states include the knives are not parallel, the blades are not in the same horizontal plane, the verticality, the balance is not level, etc. Problems of beam parts include balance stones, center of gravity stones, loose screws of middle knives and side knives, and knife damage. Environmental factors such as temperature fluctuations, airflow, humidity, etc., affect the various components of the balance, resulting in changes in the indications.

Maintenance

The maintenance of electronic balances needs to keep the balance room clean, tidy and dry, and avoid washing, dining, smoking and other activities indoors. The electronic balance should be kept and maintained by a special person, and a technical file bag should be set up, and the measurement performance should be regularly tested, and the problem should be sent for repair in time. The weighing pan, housing and windshield should be cleaned frequently, with a non-corrosive desiccant and replaced regularly. If you find any abnormalities after turning on the machine, you should immediately turn off the balance and check the power supply and connection parts.

With these measures, the accuracy and long-term stability of the electronic balance can be ensured, thereby improving the efficiency and accuracy of laboratory work.