各种油漆材料能在多方面被用作电介质。

随着绝缘材料在其物理机械性能方面以及在电特性方面的使用范围的不同,对绝绿材料提出不同的要求。

对电绝缘涂料所提出的一系列的特殊条件,就引起了按照器物(工件)的使用条件制定新试验方法的必要性(在毎一种单独的情况下)。

本章只简略叙述几种鉴定电绝织油漆材料之广量所用的电试验法。

物理机械试验法及其他试验法,除了两种只用来试验电绝缘材料的特殊方法外,都已写在本书有关各章;而这两种特殊的方法是在本章叙述的,即用以进行清漆渗透性能的测定及对喷雾试验的稳定性的测定。

漆膜击穿强度的测定

标志绝绿淸漆和磁漆是否合于绝织用途的重要性能之一就是它的绝绿强度(击穿强度)。

为了测定绝缘强度,漆膜系以卷烟纸(电容器纸)或铜片浸入试料中制成的。其浸入和取出均在]8~20°C以每分钟不超过350毫米的均匀速度进行。

为了制出厚度均匀的漆膜,其最后一层系以相同的方法涂在翻转180°角的试板上。温度和干燥时间(烘干或空气干)均按技术条件确定00x180毫米,厚度0.015毫米的电容器纸及尺寸为200x「5毫米-,厚度0.5毫米的铜片(按照「OCT2256-43利用尺寸为150x120毫米,厚度0.1~0,2毫米的金属板)。漆膜的厚度需要是均匀的(0.045~0_055毫米)。(相关仪器:测厚仪、烘箱)

使已按技术条件干燥漆膜经受击穿试验。漆膜一般在室温(20°C准确到±5°C)下,于干操状态中井在水的作用后进行试验。在特殊情况下.,试验须在高温(例如105°C)下进行;为了进行这样的试验,在毎次击穿试验前,都须把漆膜存置在恒温器中4~5分钟。(相关仪器:恒温恒湿试验箱)

水作用前漆膜击穿强度的测定

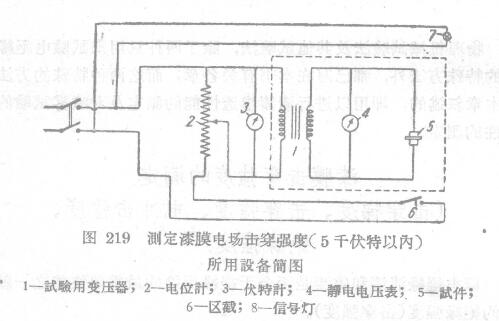

试验是在一种配有功率不低于2千伏安的变压器的设备(图219)上进行的。变压器需要装配这样一种调整装置,它能够顺利地改变不超过100伏特的高压绕组中的电压。

击穿强度的测定是在短时间电压作用下进行的。加在试件上的电压,在从零到开始击穿时应以每秒约500伏特到l000伏特的速度均匀地提高。

Voltage measurements are made by means of a voltmeter connected to the low voltage side.

The dielectric strength of the paint film is measured between simple electrodes (its side is a circle with a radius of 2-5 mm) with a diameter of 25 mm. The lower electrode needs to be grounded; the upper electrode should weigh 0.5 kg. Electrodes need to be clean and shiny at all times. The breakdown is carried out at 8~10 of the test piece. After the breakdown test, measure the thickness of the paint film as close as possible to the breakdown (with an accuracy of 5µ).

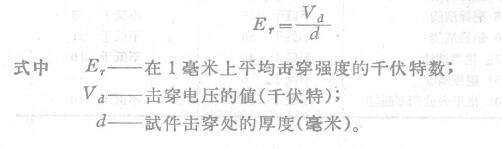

The breakdown strength of the tested paint film is represented by the quotient obtained by dividing the breakdown voltage index by the thickness of the paint film at the breakdown point, and it is measured by the arithmetic average breakdown strength at 8-10 points:

Determination of strong shock for paint film breakdown after water action

The test panels coated with the paint film were placed in distilled water at room temperature in a vertical orientation for 24 hours. After taking out the test panel from the water, remove the residual moisture from the surface of the paint film with filter paper, and then carry out the breakdown test by the above-mentioned method.

The stability of varnishes to water can also be determined by other methods. That is, apply the tested varnish on the copper plate, and after dry operation, there are four dark die rings fixed on the formed paint film (the diameter of the die ring is about 63 mm, and the height is about 3.2 mm); The cylinder is filled with distilled water. After 24 hours, pour off the water, dry the paint film with filter paper, and then dry the paint film at 20~25°C for 5 minutes, then measure the dielectric strength of the part of the paint film soaked in water and the strength of the paint film that has not been exposed to water. The absolute strength of the part of the paint film that has passed. Compare the values obtained from the two. The film thickness tested shall be the same at any point. (Related instrument: drying time Tester)

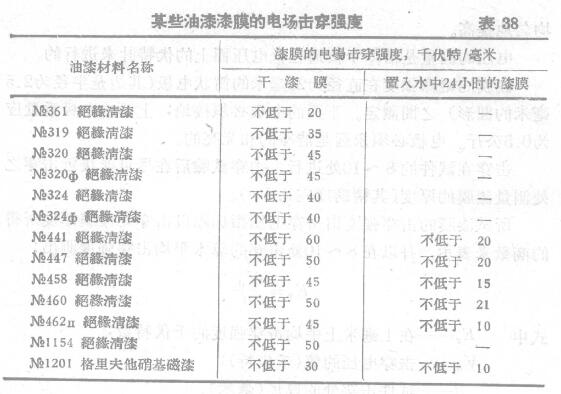

Table 38 lists the breakdown strength indicators of the paint film of some paint materials according to the existing technical conditions.