introduction

As one of the important representatives of clean energy, hydrogen fuel cells have broad application prospects in electric vehicles, renewable energy storage and other fields. Among them, the membrane electrode thin film, as a key component of hydrogen fuel cells, directly affects the performance and stability of the battery. In this article, we will discuss in depth the preparation process of hydrogen fuel cell membrane electrode films and their commonly used performance evaluation methods in laboratory research.

1. Preparation process

1.1 Substrate preparation

The preparation of membrane electrode films for hydrogen fuel cells begins with the selection of a suitable substrate. Commonly used substrates include carbon cloth, carbon paper, or other materials with good conductivity. These substrates must not only have good electrical conductivity, but also need to be suitable for the subsequent coating process.

1.2 Preparation of electrode catalyst layer

Coating the electrode catalyst on the substrate is one of the key steps in the preparation of membrane electrode films. Common electrode catalysts include platinum (Pt), platinum-iridium alloys, etc. Coating can be performed by scraping, spinning, spraying, or other coating methods to ensure a uniform and active catalyst layer on the surface of the substrate.

1.3 Coating preparation

Preparation of ionic conductive films is another important step. Hydrogen fuel cells typically use proton exchange membranes (PEMs) as the ionic conductive layer, and common materials include polytetrafluoroethylene (PTFE). The preparation process of the film layer involves dissolving the polymer material in an appropriate solvent and forming a uniform film layer by spin coating, coating, etc.

1.4 Membrane electrode layer assembly

Assembling the electrode catalyst layer and the ionic conductive film layer together is the final step in the preparation of the membrane electrode film. In this step, adhesives or heat pressing are often required to ensure tight interlayer bonding to improve the stability and performance of the overall membrane electrode.

1.5 Follow-up Processing

After the preparation of the membrane electrode film, some subsequent processing steps may be required, such as removal of solvent residues, curing, or activation of the electrode catalyst. These processing steps help to optimize the structure and performance of the MEA, ensuring that it exhibits good stability and electrochemical performance in battery operation.

2. Performance evaluation

The performance evaluation of membrane electrode films for hydrogen fuel cells is one of the key points of research, and the following are common performance evaluation methods:

2.1 Electrochemical activity test

Electrochemical activity testing is an important method to evaluate the ability of membrane electrode films to catalyze hydroxide and oxygen reduction reactions in electrolytes. The activity of the MEA is mainly determined by cyclic voltammetry (CV) and linear scanning voltammetry (LSV).

2.2 Proton conduction performance measurements

Proton conduction performance is a key indicator to evaluate the quality of ionic conductive coatings. The proton conduction performance of membrane electrode films can be evaluated by measuring conductivity, ion impedance, etc.

2.3 Durability test

Hydrogen fuel cells need to be durable in practical applications. The durability of membrane electrode films is evaluated through long-term stability tests or tests that simulate harsh environments, such as performance at high temperatures, high humidity, or high pressures.

2.4 Structural and morphological analysis

The morphology of the membrane electrode film was characterized, including the surface roughness, the bonding of the electrode catalyst layer and the ionic conductive film, etc. Commonly used characterization techniques include scanning electron microscopy (SEM) and atomic force microscopy (AFM).

2.5 Battery performance test

Integrate membrane electrode films into complete fuel cell systems to test the overall performance of the battery. It mainly includes measuring current density, power density, polarization curve, etc., to evaluate the performance of the membrane electrode under actual operating conditions.

3. Applicable type of Film Applicator

In laboratory studies, the following types of coaters are commonly used for the preparation of hydrogen fuel cell membrane electrode films:

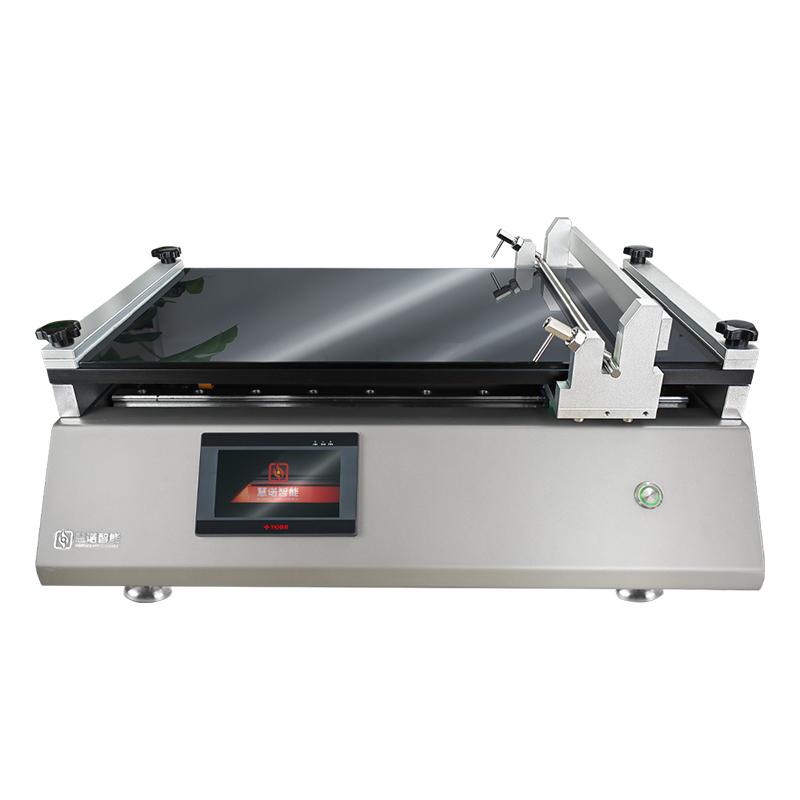

3.0 Wire rod coating machine

Wire rod coating machine is a common coating film experimental equipment, scraping through the wire rod, the film thickness is controlled by the wire diameter of the wire rod, due to the high coating accuracy of the wire rod, it is suitable for high-precision ultra-thin coating film, and the coating film thickness ranges from 1.5~200 microns.

3.1 Spin Coater

Spin Coaters are common lab equipment that are particularly suitable for coating uniform films. When preparing the electrode catalyst layer or ionic conductive film layer, the spin coating speed and time can be controlled by the Spin Coater to make the solution form a uniform film layer on the substrate.

3.2 Spraying machine

Sprayers use spray technology to evenly spray the solution onto the surface of the substrate. This method is suitable for coating larger areas of thin films, which allows for faster preparation of electrode layers in the laboratory.

3.3 Manual application

For simple laboratory studies, manual coating methods such as using a brush or cotton swab to evenly coat the substrate are also sometimes chosen, and while this method may not be as precise and consistent as mechanized coating equipment, it can still provide good results in some cases.

3.4 Vacuum deposition machine

For specific electrode materials, such as certain metals or metal compounds, thin films can be prepared using a vacuum deposition machine. This method is typically used to prepare very thin electrode layers.

Choosing the type of coater usually depends on the research needs of the lab and the budget available. Wire rod coaters and Spin Coaters are common choices because they are simple to operate and provide good film uniformity and control.

conclusion

The fabrication and performance evaluation of membrane electrode films for hydrogen fuel cells is a complex and critical research area. Through the precise control of the preparation process and the comprehensive application of a variety of performance evaluation methods, the performance and stability of the membrane electrode film can be effectively improved, and the development and application of hydrogen fuel cell technology can be promoted.