In the research and development process of PET (polyethylene terephthalate) film, it is very important to choose the right film coater, which can not only affect the accuracy and consistency of the coating effect, but also directly related to the reliability and practicability of the experimental results. This article will discuss the common types of glue applied to PET film, the key points for selecting a coating machine, and the performance testing after coating, aiming to provide scientific researchers with a comprehensive guide to laboratory film coating machines.

Common types of gluing on PET film

The choice of gluing on PET film often depends on the specific application needs and requirements, and common types of gluing include:

Pressure-sensitive adhesive: This glue is highly adhesive and can be bonded without heat or solvents, making it suitable for the manufacture of labels, tapes, and other products.

Hot Melt Adhesive: Hot melt adhesive becomes a flowing state after heating, and after being applied to PET film, it cures quickly to become an adhesive layer, which is suitable for applications that require high viscosity and fast curing.

UV-curable adhesives: Formed by UV light to form an abrasion-resistant, chemical-resistant, and temperature-resistant adhesive layer, and are commonly used in applications that require fast curing and high strength.

Water-based glue: A glue that uses water as the main solvent, which is environmentally friendly and forms an adhesive layer after the water evaporates after application, which is suitable for environmentally friendly coating film needs.

Each type of gluing affects the different properties of PET film after coating, so choosing the right type of gluing needs to be evaluated according to the specific application needs and performance requirements.

Performance testing of PET film after gluing

Glued PET films often require a variety of performance tests to ensure they meet the requirements of a specific application:

Adhesion——The adhesion strength of the glued to the PET film is evaluated, often measured by a peel force test.

Chemical resistance——The resistance of the glued film under the action of different chemicals (such as solvents, acids and alkalis, etc.) is tested to confirm its stability in actual use.

heat tolerance——Evaluate the stability and performance of the applied film at high temperatures to ensure that it does not fail or decompose during processing or use.

Moisture resistance——Measure the resistance of glue coatings to moisture and moisture to avoid moisture, blistering, or degradation of performance.

Optical Transparency – Evaluates changes in the transparency of PET film after gluing to ensure that the coating does not affect the visual quality of the film.

These performance tests help determine the final quality and suitability of the glued PET film, ensuring that it will work well in the specific application environment.

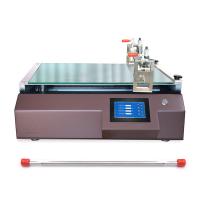

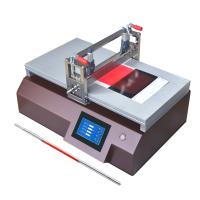

A key factor in choosing a Film Applicator

When selecting the right laboratory coater for PET film research, the following key factors need to be considered:

Coating techniques and requirements. Choose a coater that can support the desired coating technology (e.g., manual application, rotary application, spraying, etc.).

Film material and thickness。Ensure that the coater can stably process the PET film and control the accuracy of the coating thickness.

Scale and speed of the experiment。Determine the processing speed and production capacity of the coater according to the experimental needs to meet the requirements of different scale experiments.

Type of glue or paint。Choosing a Film Applicator based on the type of glue to be applied ensures that the machine can adapt to the required coating process and chemicals.

Automation and control systems。Modern Film Applicators are often equipped with a high degree of automation and precise control systems to improve production efficiency and product quality.

summary

When selecting a suitable coater for PET film research, it is necessary to consider the type of glue, performance testing, and the technical characteristics of the coater itself to ensure the accuracy and reproducibility of experimental results. Scientific researchers should choose the appropriate coating machine equipment according to the experimental needs and technical requirements to support the innovative research and application development of thin film materials.