The proliferation of electric vehicles and portable electronic devices has made lithium-ion batteries one of the most important energy storage solutions today. However, with the diversification of battery application scenarios, how to ensure the safety of batteries during use, transportation, storage and handling has become an important technical challenge. In order to evaluate the safety performance of batteries in the face of external extrusion and needling, the battery extrusion needle punch Tester was developed.

The principle of a battery extrusion needlestick testing machine

The battery extrusion needle punch testing machine mainly evaluates the safety performance of the battery under these conditions by simulating the mechanical stress that the battery may encounter in real-world application scenarios. The main tests include the extrusion test and the needlestick test:

Extrusion test:

The extrusion test involves the hydraulic arm applying a controlled extrusion force (typically about 13 kN), continuously squeezing the cell until a set maximum pressure (e.g. 17 MPa) is reached, and then the extrusion is released. This process simulates the mechanical squeeze that the battery may experience in an accident. The battery response is monitored during the test, including voltage, temperature changes, and whether there are signs of fire or explosion.

The extrusion test simulates the mechanical extrusion that the battery may be subjected to in an accident situation, such as crushing, flattening, etc. This test evaluates the safety performance of the battery in the event of a crush by applying a controlled pressure.

【Test Equipment】

Hydraulic arm – used to apply a controlled squeezing force.

Pressure sensor – used to monitor and record the pressure applied to the battery.

Control system – used to adjust and record test parameters such as application pressure and time.

【Procedure】

(1) Place the tested battery on the test bench, make sure the battery is directly below the hydraulic arm.

(2) The hydraulic arm starts to apply pressure, usually around 13kN, until it reaches the set maximum pressure (such as 17MPa).

(3) After continuously squeezing the battery for a period of time, record the response of the battery, including voltage changes, temperature increases, and whether there is a fire or explosion.

(4) Release the pressure, end the test, and analyze the recorded data.

Crush tests can be used to evaluate the safety performance of batteries in the event of a crash or crush, helping to design more durable and safe battery packaging and construction.According to the test results, the battery design was optimized to improve its bearing capacity and safety under extrusion conditions.Comply with relevant international standards and industry requirements, such as UN38.3 standard, to ensure the safety of battery products during transportation and use.

Acupuncture test:

The pinprick test places the battery in a fume hood using a stainless steel needle with a diameter of 3 mm and pierces vertically into the center of the cell surface at a controlled speed (20 mm/s to 40 mm/s). This test simulates the possible penetration of sharp objects into the battery and evaluates the battery's safe response in such situations, in particular whether a fire or explosion will occur.

【Test Equipment】

Acupuncture device – stainless steel needles with a diameter of 2-8 mm are usually used.

Control system – used to control the speed and depth of needling and to record relevant data.

【Procedure】

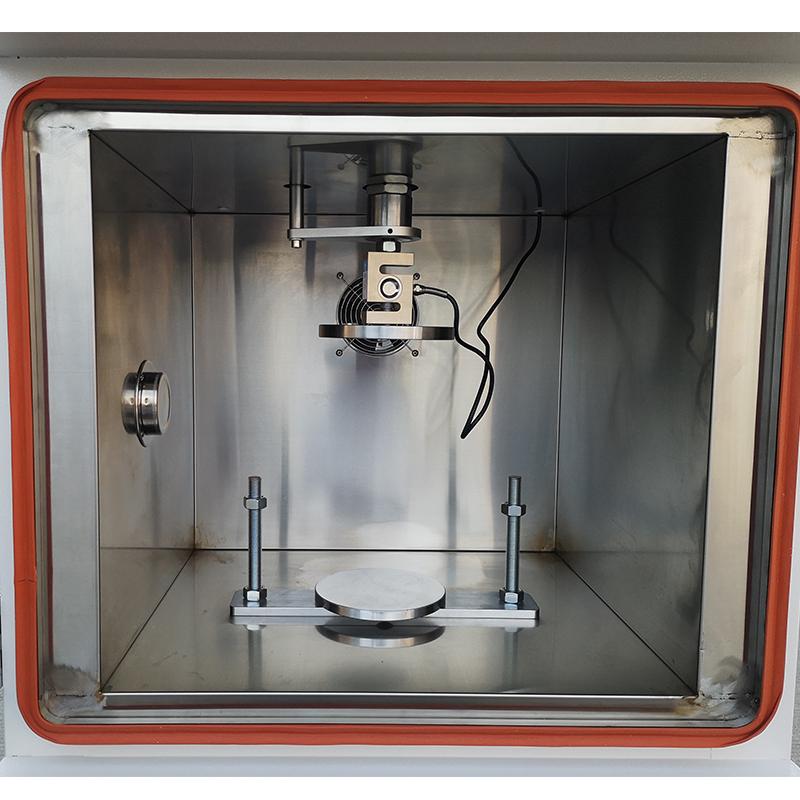

(1) Place the battery in the Test Chamber and make sure the ambient temperature is stable at 20°C±5°C.

(2) Use a stainless steel needle at a preset speed (e.g., 20mm/s to 40mm/s) to pierce vertically into the center of the battery.

(3) Monitor the battery's response during the process, including whether there is a fire, explosion or other abnormal phenomena.

(4) According to the purpose of the test and the standard requirements, single or multiple acupuncture can be performed.

Evaluate the safety performance of the battery in the event of accidental pinprick to prevent accidents that may occur in actual use.According to the test results, the battery shell and structural design are improved to improve its resistance to mechanical damage.Ensure that battery products comply with the requirements of relevant safety standards and regulations, such as UN38.3 and IEC 62133.

Application & Significance

The battery extrusion needle punch testing machine has important application value in the R&D, production and safety management of lithium-ion batteries.By simulating extreme conditions in real-world scenarios, such as crushing and needling in accidents, the safety performance of batteries is evaluated to help design safer and more reliable battery systems.The testing machine can collect the voltage, current and resistance data of the battery in real time and accurately, and display and save it in the form of curves and databases, providing an important reference for battery design and optimization.Complying with international standards and industry requirements, such as the Safety Requirements for Powertrain Batteries for Electric Vehicles, helps battery manufacturers ensure that their products meet relevant safety standards and comply with legal and regulatory requirements.Some advanced acupuncture methods, such as direct observation of the internal chemical reactions of batteries by X-ray technology, are promoting the progress of lithium battery safety research and providing technical support for the development of safer and more efficient battery technology in the future.

As a key equipment to evaluate the safety performance of lithium-ion batteries, battery extrusion needle punch testing machines play an irreplaceable role in electric vehicles and portable equipment. With the continuous progress of battery technology and the expansion of application scenarios, the high standard requirements for its safety performance make the development and innovation of this type of test equipment particularly important. In the future, with the advancement of technology and the deepening of research, battery extrusion needle punch testing machines will continue to play a key role in battery safety evaluation and product optimization.