Viscosity is a key physical property in modern industry and scientific research that directly affects the performance and effectiveness of liquids in a variety of processes and applications. Accurate viscosity measurement is crucial not only in the petroleum, chemical and food industries, but also in the pharmaceutical, coatings and cosmetics sectors. To meet the needs of different applications, scientists and engineers have developed a variety of viscometers, each based on a unique measuring principle, such as capillary viscometers, Rotational Viscometers, falling ball viscometers, and vibratory viscometers. This article will delve into how these viscometers work, their areas of application, and their importance in industry and laboratories. By understanding the characteristics of different viscometers, we can better understand and utilize viscosity measurement techniques.

1. Capillary viscometer

principle

A capillary viscometer measures viscosity using the resistance of a liquid to flow through a thin tube. According to the Posu leaf formula, the viscosity can be calculated. Typical capillary viscometers include Ubelot type, Obin type, etc.

apply

It is mainly used to measure the kinematic viscosity of petroleum products, chemical products, etc. Capillary viscometers are suitable for liquids with low viscosity, with a wide measuring range and high accuracy.

2. Rotational viscometer

principle

A Rotational Viscometer determines viscosity by rotating a cylinder or disc in a fluid, measuring the viscous resistance experienced. When measured, viscosity is related to the required torque or angular velocity of rotation.

apply

It is suitable for dynamic viscosity measurement of a wide range of liquids, including highly viscous liquids and semi-solid substances. Common Rotational Viscometers are the Brookfield Viscometer and the Haake Viscometer.

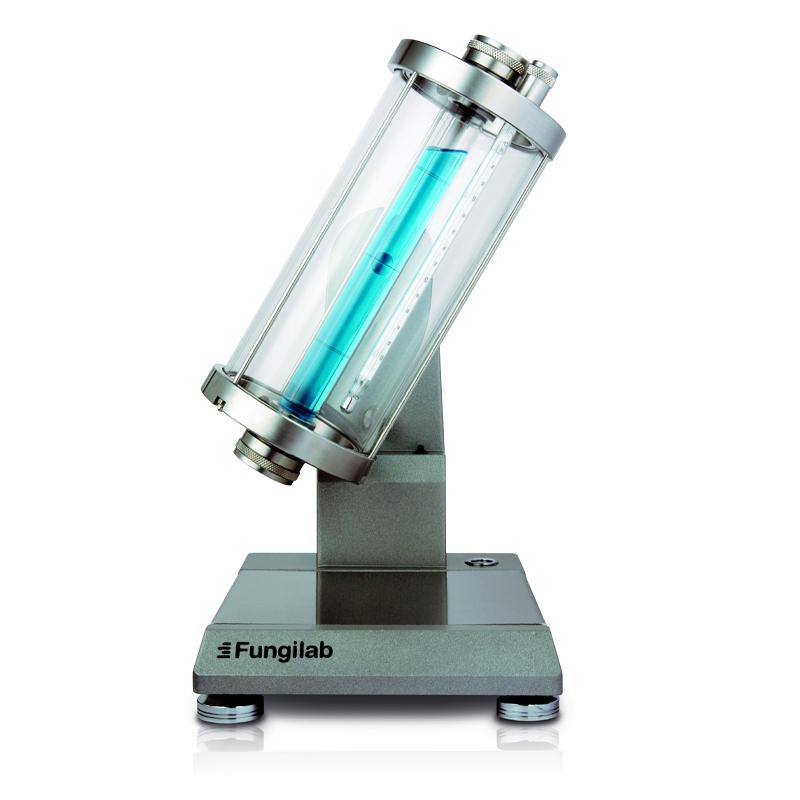

3. Falling ball viscometer

principle

A falling ball viscometer measures the viscosity of a liquid using the viscous resistance experienced by a solid ball as it falls freely in a liquid. The viscosity is calculated based on the density of the ball, the density of the liquid, and the time it takes for the ball to fall.

apply

It is mainly used for viscosity measurement of transparent liquids, such as paints, solutions, etc. Common types include vertical ball drop and inclined ball drop, which have a wide range of applications and are easy to measure.

4. Vibratory viscometer

principle

A vibratory viscometer measures the viscosity of a liquid using the damping experienced by a solid as it vibrates in a liquid. The magnitude of viscosity is determined by measuring the degree of attenuation of vibration.

apply

It is mainly used for rapid viscosity measurement of liquids, such as quality control of solutions, coatings, etc. in the paint industry. Common vibratory viscometers include ultrasonic vibratory viscometers and reed vibrating viscometers.

A capillary viscometer measures viscosity using the time it takes for a liquid to flow through a capillary. The common ones are Ubelot type, Aoping type, etc., which are suitable for accurately measuring the kinematic viscosity of petroleum products and light chemical products. whereasA Rotational Viscometer measures viscosity by the resistance experienced by a cylinder as it rotates in a fluid. It can be divided into different types according to the way of pushing the passive cylinder and the way of measuring angular velocity, which is suitable for the determination of dynamic viscosity of various fluids.A falling ball viscometer measures viscosity by the time it takes for a solid ball to fall freely in a liquid. It is suitable for viscosity measurement of transparent fluids, and is often used when a wide range of liquid viscosity and high accuracy is required. As forVibrovisometers measure viscosity by using the viscous damping of solids when they vibrate in a fluid. For example, ultrasonic vibrating viscometers are suitable for rapid measurement of the viscosity of liquids in the paint industry and the chemical industry.Each viscometer has its own unique measuring principle and range of application. Choosing the right viscometer depends on the properties of the liquid to be measured, the viscosity range, the measurement accuracy requirements, and the conditions of the laboratory or industrial environment. Viscometers have a wide range of applications in petroleum, chemical, food, pharmaceutical and other fields, and play a key role in product quality control and process optimization.