The purpose of the determination of spray stability is to determine whether the varnish will spray under the action of centrifugal force when the varnish is applied to a rapidly rotating workpiece.

When there is no special provision in the technical conditions, the test is carried out at 90°C. The varnish to be tested is brushed into a thin layer of about 0.15 mm thick on the cotton cloth strip, so that the entire cloth strip is evenly penetrated by the varnish on the entire (entire) thickness (priming with varnish). With the cloth strip thus prepared, after pre-drying, apply the varnish to be tested evenly from one side by means of a brush. (Related Instruments: Thickness Gauge)

After the varnish is applied, dry the cloth strip in the air at 20°C (±5°C) or in a thermostat at 105~110°C (the drying time and temperature of the cloth strip coated with each paint are different. specified in the corresponding technical conditions). (Related instruments: constant temperature and humidity Test Chamber)

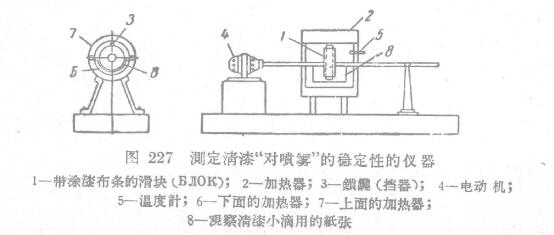

The varnished and dried cloth strips are placed in a special instrument (Fig. 227), which is a metal disc 1 with a diameter of 180 mm, which is placed in a heater 2 consisting of two parts. The upper part (of the heater) can be removed in order to secure the strip to the pan. The fixing of cloth strip can be carried out by drilling key (stopper) 3. To rotate the disc, the motor 4 is used. The temperature system in the instrument is measured with a thermometer 5 .

On the lower part 6 or the upper part 7 of the heater, a pack of white writing paper 8 is fixed, and this paper is used to observe the varnish droplets falling from the surface of the rotating painted cloth strip.

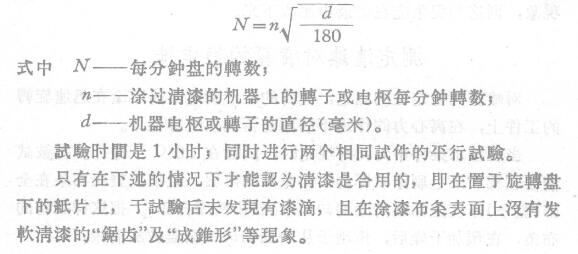

In order to obtain the necessary centrifugal force, the rotation speed of the disc (at a diameter of 180 mm) should be equal to 2500 rpm increase. The number of revolutions can be obtained by the following formula: