In the coating process, accurately calculating the amount and thickness of the paint used is a critical step in ensuring the quality of the coating and controlling costs. Volumetric solids is an important indicator to measure the proportion of active ingredients in coatings, and by accurately calculating them, we can better guide the thickness control and coating rate evaluation during coating application. In this paper, we will introduce the calculation method of volumetric solids in detail, and discuss how to calculate the wet film thickness, diluted wet film thickness, theoretical coating rate and actual coating rate under different conditions, combined with the relationship between dry film thickness and wet film thickness, so as to help coating practitioners better grasp these key parameters.

Calculation of volumetric solids

% Volume Solids is an important parameter to measure the proportion of non-volatile components in a coating. This metric is critical to understanding the actual coverage and thickness control of the coating.

Most paint manufacturers, including international paint companies, use volumetric solids calculations under laboratory conditions, according to the methods described in the Determination of Solid Content in Paints and Paints (by Volume) in Volume 4 of the Paint and Pigment Chemist (OCCA) Monograph. The specific steps are to measure the wet film thickness before drying and the dry film thickness after drying, and calculate it according to the following formula:

Volume solids = dry film thickness ÷ wet film thickness

Assuming that a coating product has a wet film thickness of 200 microns and a dry film thickness of 100 microns, the volume solids are calculated:Volume solids = dry film thickness÷ wet film thickness = 100÷200 = 50%,As a result, the coating product has a volumetric solids content of 50%.

Wet and dry film thickness

During the coating process, the coating thickness can be measured in both wet and dry film states.

Dry Film Thickness (DFT): Usually specified in the coating contract.

Wet Film Thickness (WFT): Measuring wet film thickness can help determine how thick a coating needs to be applied to achieve a specified dry film thickness. The measurement of wet film thickness helps to detect and correct the thickness deviation of each coating in a timely manner.

However, on steel and most metal components, wet film measurements are primarily used as a guide, while dry film thickness is actually recorded.It is important to understand the relationship between wet and dry film thickness. When the dry film thickness is specified in the coating specification, the corresponding wet film thickness range needs to be known to ensure that the dry film thickness is within the specified range.The ratio of wet film thickness to dry film thickness depends on the volumetric solids percentage of the paint used, which can be obtained from the paint manufacturer's technical datasheet. When making calculations, volumetric solids are a key parameter.

Wet film thickness calculation formula

Knowing the specified dry film thickness and volumetric solids, the corresponding wet film thickness can be calculated using the following formula:

Wet film thickness = dry film thickness ÷ volumetric solids

Assuming that the volume solids of an epoxy micaceous iron primer is 80% and the dry film thickness is required to reach 150 microns (6 mils), then calculate the required wet film thickness = dry film thickness ÷ volume solids = 150÷0.8 = 187.5 μm.

Wet film thickness after dilution

In actual construction, a certain amount of thinner is often added to the paint. The use of diluent increases the total volume, but not the volumetric solids.

For example, if a 25% diluent is added, this dilution needs to be taken into account in the calculation.

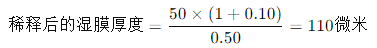

To calculate the thickness of the diluted wet film, this can be done according to the following formula:

Diluted wet film thickness = [dry film thickness× (1 + dilution ratio)] ÷ volume solids

![Diluted wet film thickness = [dry film thickness× (1 + dilution ratio)] ÷ volume solids](http://img.nbchao.com/upload/editor/image/20240717/1721203461025049069.png)

Assuming that the volume solids of a polyurethane topcoat is 50%, the specified dry film thickness is 50 microns, and the dilution is 10%, then calculate the required wet film thickness = [50×(1+0.1)÷0.5=110 μm.

Theoretical coating rate

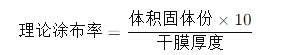

The theoretical coating rate is the area (square meters) that can be covered per liter of paint under ideal conditions, and is measured in m²/L. The calculation formula is as follows:

Theoretical coating rate = (volumetric solids ×10) ÷ dry film thickness

Assuming that the volume solid content of an inorganic zinc-rich primer is 63% and the specified dry film thickness is 75 microns, the theoretical coating rate = (63×10) ÷ 75 = 8.4 square meters/L.

Calculation of the actual coating rate

The actual coating rate is the coating rate after taking into account the construction loss. It is calculated as follows:

Actual Coating Rate = Theoretical Coating Rate × (1 - Percentage of Loss)

Assuming that the volume solid content of an inorganic zinc-rich primer is 63%, the dry film thickness of 75 microns is sprayed, the loss is 40%, and the theoretical coating rate is 8.4m²/L, the actual coating rate is calculated as follows:

Actual coating rate = 8.4× (1-0.4) = 5.04㎡/L

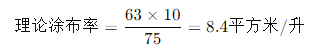

Calculation of the actual amount of paint used

The actual amount of paint used is calculated based on the actual coating rate and can be calculated according to the following formula:

Actual use of paint = (area × dry film thickness) ÷ [10 × volume solids× (1 - loss percentage)]

![Actual use of paint = (area × dry film thickness) ÷ [10 × volume solids× (1 - loss percentage)]](http://img.nbchao.com/upload/editor/image/20240717/1721203665876007844.png)

Assuming that the inner wall area of a storage tank is 2000 square meters, spraying two layers of phenolic epoxy paint, each 150 microns, and the estimated loss is 40%, then the amount of each coating = (2000×150)÷ [10×0.75×(1-0.4)] = 658L

![Paint amount = (2000×150)÷ [10×0.75×(1-0.4)] = 658L](http://img.nbchao.com/upload/editor/image/20240717/1721203683482095740.png)

Through the above calculations, the amount of paint used can be effectively planned, and the construction quality and cost control can be ensured.

In short, mastering the key parameters in the coating calculation, such as volumetric solids, dry film thickness, wet film thickness, theoretical coating rate and actual coating rate, can not only improve the construction quality, but also effectively control the amount and cost of coating. In actual construction, the reasonable application of these calculation methods can find and correct the thickness error in construction in time to ensure that the coating achieves the expected protective effect. It is hoped that the calculation methods and examples described in this article will provide a useful reference for painting engineers and technicians to achieve more accurate and efficient painting operations.