In the laboratory and industry, film coaters are used to precisely coat a wide range of substrates to ensure product quality and consistency. However, when it comes to special application requirements, especially when it comes to coaters that operate at high temperatures, choosing the right heating method is key. NBCHAO will discuss with you the technical characteristics of the ultra-high temperature Film Applicator, and compare the advantages and disadvantages of mica heating sheets and graphene Heating Plates.

Requirements for ultra-high temperature Film Applicators

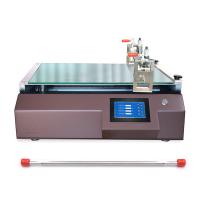

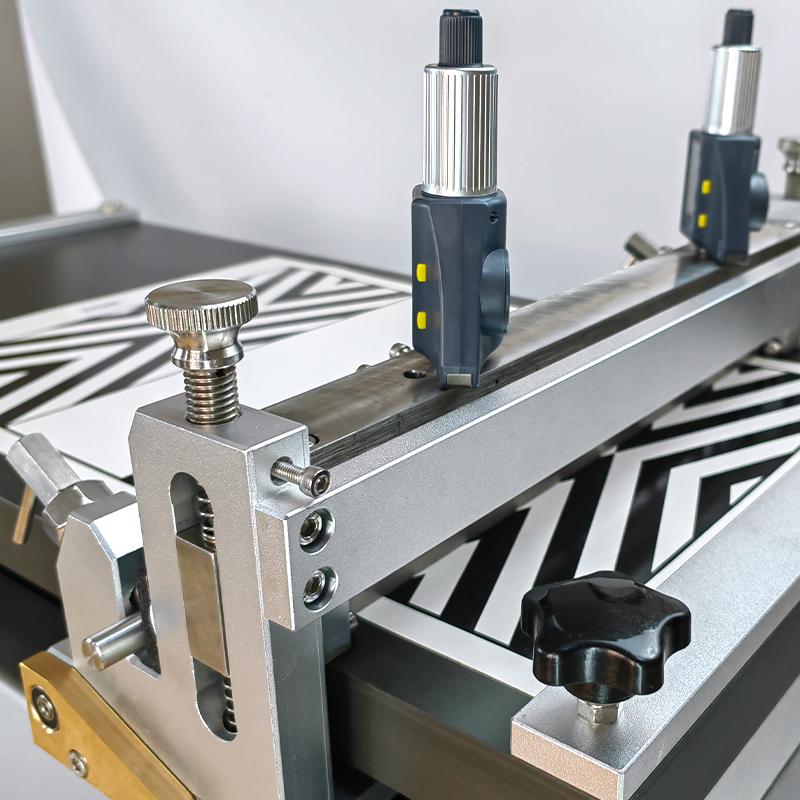

For some applications, such as a coating process that requires a coating process lasting 10-20 minutes at 260°C, conventional coaters cannot meet this high temperature requirement. In this case, the coater must have a special design and materials to accommodate high-temperature operation. The Heating Plate is designed with special thermal insulation materials and Heating Plates, and the temperature control accuracy of the Heating Plates can reach ±1°C, ensuring that the temperature difference does not exceed ±1°C in the coating area of 450x250mm. This accuracy is determined by the uniformity of the heating wire arrangement, but the Huinuo film coating machine does not rely only on the heating wire, but uses the integral Heating Plate of the mica heating sheet composite with the stainless steel shell.

Comparison of mica heating sheets with graphene Heating Plates

Mica heating sheet

The mica heating sheet is wound around the mica sheet, and the heat generated by heating the resistance wire is then conducted to the mica sheet. The main advantages of this heating method include low cost and good soaking performance.

Compared to graphene, the cost of processing and producing mica heating sheets is lower.The mica material itself has good soaking characteristics, but due to the difference in the distribution of resistance wires, there may be some unevenness in the transfer of heat on the chip.

However, mica heating sheets also have their limitations.Due to the way the resistance wires are distributed, heat transfer across the mica sheet may not be uniform enough, resulting in localized overheating or overcooling.The heat conduction efficiency of mica sheet is not as good as that of graphene, and the heating time is longer.

Graphene Heating Plates

The graphene Heating Plate uses graphite material as the heating element, and generates Joule heat inside the graphite through an electric current to achieve heating. Key benefits include:Excellent thermal conductivity,Uniform heating as wellFaster heating speed.

Graphite has extremely high thermal and electrical conductivity, and heat is transferred quickly and evenly inside the graphite plate.The overall heating performance of graphene is better than that of mica flakes, which can provide a more uniform heating effect.Due to graphite's excellent thermal conductivity, graphene Heating Plates are able to reach the required temperature more quickly.

However, the disadvantages of graphene Heating Plates are:Graphene materials are costly, and the use of such Heating Plates can significantly increase the overall cost of the equipment. Other than thatIn order to adapt to the high temperature environment, additional modifications and optimizations may be required to the equipment.

Vacuum adsorption function with high temperature limiting

To ensure the flatness of the film substrate, some coaters are equipped with a vacuum adsorption function, which is especially important for soft films. However, at high temperature operation, existing vacuum tubing and fittings may not be able to withstand temperatures up to 200°C, resulting in deformation of vacuum tube fittings. Therefore, if the vacuum adsorption function is to be used in a high-temperature environment, it is necessary to design the vacuum system or select materials that can withstand high temperatures.

When choosing a high-temperature film coating machine, mica heating sheets and graphene Heating Plates have their own advantages and disadvantages. Mica heating sheets are less costly, but the heat distribution may not be as uniform as graphene. Although the price of graphene Heating Plate is higher, it has better performance in uniformity and heating efficiency. For applications that require coating at high temperatures, it is critical to choose the right heating method and system design to ensure the stability and quality of the coating process.In the design of future high-temperature coaters, factors such as cost, heating efficiency, and uniformity may need to be considered to meet the needs of different applications.NBCHAO has a full set of mature coating film solutions, and the specific needs can be consulted with our engineers.