introduction

The basic principle of measuring starch viscosity by Rotational Viscometer is to use the gelatinization behavior of a sample within a certain temperature range to measure its viscosity change by a Rotational Viscometer. As the temperature increases, the starch sample gradually gelatinizes, changing its viscosity. A Rotational Viscometer can accurately measure this change and provide quantitative data on viscosity values.

principle

The gelatinization process of starch refers to the fact that under heating conditions, starch granules absorb water and swell and gradually rupture, releasing starch molecules to form a viscous paste-like substance. As the temperature increases, the moisture in the starch granules increases, which weakens the interaction force of the starch molecular chains, causing the granules to swell and eventually disintegrate. In this process, the viscosity of the starch increases significantly with increasing temperature. By monitoring the effect of temperature changes on starch gelatinization, detailed information about starch viscosity can be obtained.

A Rotational Viscometer determines the viscosity of a liquid by measuring the resistance of a rotating rotor. The rotor inside the instrument rotates in the sample liquid, and the viscosity of the liquid creates resistance to the rotation of the rotor, which is recorded by the rotor and the instrument's sensors. The viscometer calculates the viscosity value of the liquid by measuring the relationship between the torque of the rotor and the speed of rotation. During the measurement, the sample is kept at a constant temperature so that the effect of temperature on viscosity can be accurately reflected.

Instruments and equipment

| Instruments and equipment | function |

| Electronic Balances | Weigh samples accurately to 0.1 g for accurate measurement of the mass of starch samples. |

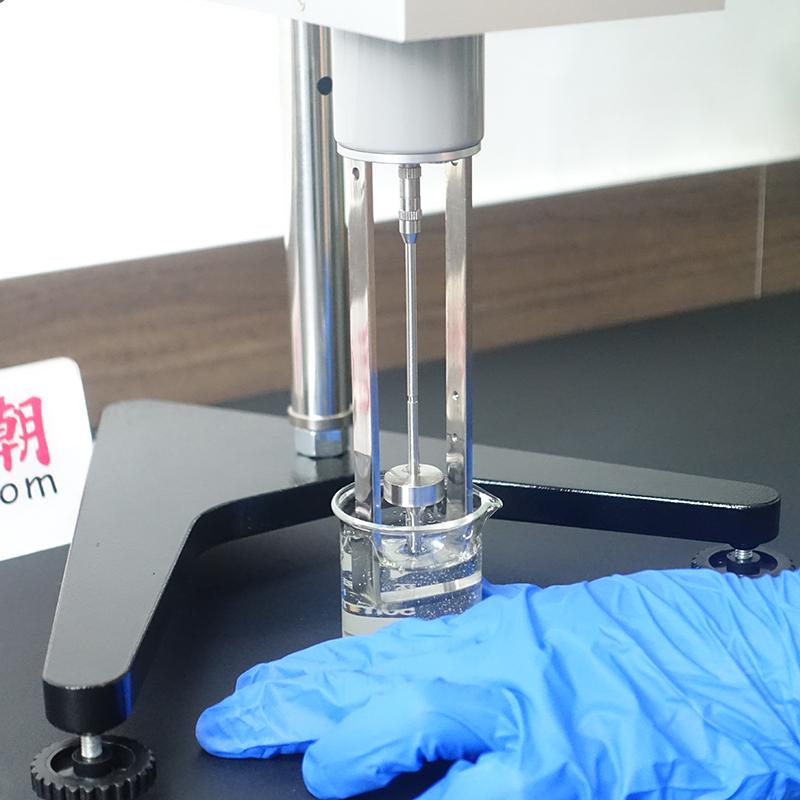

| Rotational viscometer | The viscosity of a liquid is measured, and the viscosity value of the liquid is determined by the resistance of the rotating rotor. Equipped with a thermal insulation device to maintain a constant temperature. |

| Freeness Tester | It is used to stir the sample to ensure that the sample is evenly dispersed in the solution, and the stirring speed is adjustable. |

| Magnetic stirrer | A homogeneous stirring is created in the liquid by means of a stir bar, which helps the sample to mix evenly. The stirring speed is adjustable. |

| Thermostatic Water Bath | Keep the sample within a specific temperature range to ensure that the starch temperature is constant during the heating process. Temperatures range from room temperature to 100°C. |

| Four-mouth flask | Solutions for the preparation of starch samples in capacities of 500 mL and 1,000 mL. |

| Tall beaker | The capacity is 250 mL for mixing and sample preparation. |

| graduated cylinder | For measuring liquids in volumes of 250 mL, 500 mL and 1,000 mL. |

| Serpentine or spherical condenser tubes | It is used to cool the steam, prevent the sample from evaporating, and ensure the stability of the sample during the heating process. |

| Mercury thermometer | Measure sample temperature from 0°C to 100°C. |

Reagent requirements

| reagent | request |

| Distilled or deionized water | It must meet the requirements of tertiary water in GB/T 6682 for dissolving starch samples and preparing sample solutions. |

| Absolute ethanol | Analytically pure, it is used to wet and disperse the sample, ensuring the uniformity of the sample in solution. |

Test procedure

1. Sample slurry

1.1 Starch treatment method without paste in cold water

Weigh the appropriate amount of starch sample (accurate to 0.1 g) and place it in a four-mouth flask.

Distilled or deionized water is added using a graduated cylinder to ensure that the sample has a set mass concentration of dry-based solids and a total volume of approximately 2/3 of the flask volume.

Place the four-pronged flask in a thermostatic Water Bath that has been warmed to 55 °C.

Install the agitator, condenser tube and thermometer, and turn on the condensate and agitator.

Heat a thermostatic Water Bath to raise the sample temperature to 92 °C to 95 °C.

After holding this temperature and stirring for a certain period of time, a sample is taken for viscosity determination.

1.2 Starch treatment method for complete swelling of cold water into paste

Weigh an appropriate amount of the modified starch sample and place it in a tall beaker.

Wet the sample with absolute ethanol and then slowly add distilled or deionized water while stirring on a magnetic stirrer for a total volume of 2/3 of the beaker volume.

Stir for 10 minutes to ensure that the sample is evenly formed into a paste and there is no clumping.

Samples are taken for viscosity determination.

2. Instrument preparation

2.1 Adjustment and Calibration

Make sure that the measuring barrel of the Rotational Viscometer is level.

Calibrate and zero according to the instrument manual to ensure the accuracy of the instrument.

2.2 Setting of the insulation device

The holding device of the Rotational Viscometer is connected to the circulation device of the thermostatic Water Bath.

According to the needs of the experiment, the temperature of the thermostatic Water Bath was set to make the temperature of the measuring cylinder consistent with the temperature of the Water Bath.

3. Assay

The prepared sample is removed from the four-mouth flask or tall beaker and added to the measuring cylinder of the Rotational Viscometer.

Select the appropriate rotor according to the characteristics of the sample.

Set the appropriate rotational speed for measurement.

Read and record viscosity values.

Precautions

Make sure that the torque of the Rotational Viscometer is within the normal operating range. If it is out of range, the speed and rotor need to be adjusted.

Depending on the experimental requirements, the viscosity of the sample after different holding times can be determined.

Rotational viscometers demonstrate a high degree of accuracy and reliability in determining the viscosity of starches. Through the guidance of this paper, researchers can systematically determine the viscosity of starch and understand the behavior and properties of starch under different conditions. This not only contributes to formulation optimization in the food industry, but also provides valuable experimental data for the field of materials science. Accurate operating procedures and precautions can ensure the validity of experimental results and lay a solid foundation for further research and application.