introduction

Paper tear is an important index to evaluate the tear resistance of paper, which is directly related to the performance and application effect of paper. Tear not only affects the stability of the paper during processing and use, but also affects the quality and durability of the final product. High tear paper can effectively reduce tear damage when it is squeezed and pulled during mechanical operation and transportation, thereby improving the reliability and durability of the product. This is especially important in the packaging industry, where the paper must be strong enough to protect the contents from external shocks and tears.

Applications include packaging paper and cardboard, where the paper needs to have a high tear degree to ensure that it can withstand various external forces during transportation and storage without being torn. Paperboard is often used in the manufacture of structural products such as packaging boxes and shelves, and its tear directly affects the overall stability and load capacity of paperboard. Correctly determining the tear degree of paper is essential to ensure that these paper products perform in real-world applications, helping to optimize production processes and improve product quality.

definition

Internal tear

Internal tear is the force required to tear a piece of pre-cut paper or cardboard, usually measured in millinewtons (mN) or crick (gf). This indicator reflects the minimum force required for the paper to be torn and provides a quantitative measure of the paper's tear resistance. A higher internal tear indicates that the paper is more resistant to tearing, making it suitable for applications that require higher strength and durability.

Tear index

The tear index is the ratio of the internal tear to the paper weight and is measured in mN·m²/g. The tear index can reflect the tear performance of the paper at a specific weight, helping to evaluate the overall tear resistance of the paper. The tear index allows for a better comparison of the tearing capacity of different papers at the same weight, thus providing a more accurate reference when selecting paper materials.

Determination principle

Paper tear is usually determined using a pendulum instrument, which tests the paper's tear resistance by applying a tearing force. The instrument's pendulum exerts a tearing force perpendicular to the specimen face as it swings freely. The magnitude of this force depends on the mass of the pendulum and the amplitude of the swing. When tearing the specimen, the movement of the pendulum will cause the paper to tear, and the instrument will measure the work done during the tearing process, i.e., the energy expended by the pendulum during the tearing process.

The tearing degree of the paper is calculated by measuring the potential energy loss of the pendulum. Specifically, during the tearing process, the potential energy of the pendulum is converted into the energy required for the paper to tear, and the instrument records this energy value and converts it into a value for the degree of tearing. The degree of tear is calculated based on the work done during the tearing process and the number of layers of the specimen, which reflects the average force required by the paper when it is torn, thus providing specific data on the tear resistance of the paper.

Instrument introduction

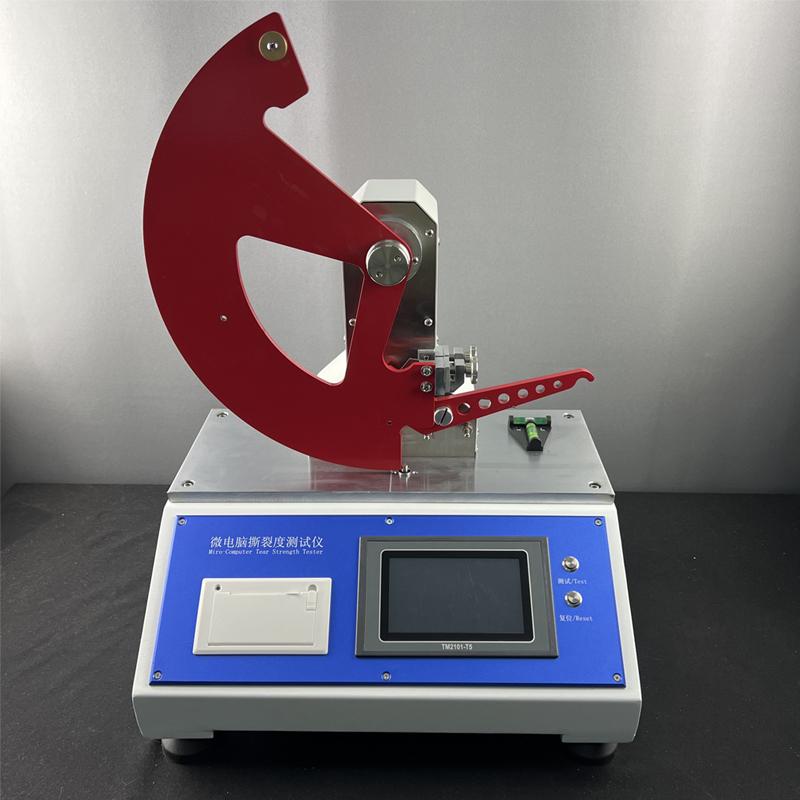

Elemendorf Single Tear Meter

The Elimendorf Single Tear Meter is a commonly used paper tear measurement tool. Its main components include a base frame, pendulum, clamping mechanism and pointer system, among others. The base frame supports the structure of the entire instrument to ensure stability; The pendulum is supported on the base frame by bearings with minimal friction, which can swing freely and exert tearing force; The clamping mechanism is used to hold the specimen in place, ensuring that it does not move or deform during the test; The pointer system is used to read the value of the tear, which usually includes a dial and a pointer.

The principle of operation of the instrument is based on the tearing force applied by the oscillating body. The specimen is fixed between two clamps, one of which is attached to the base frame and the other to the pendulum. The pendulum exerts a tearing force perpendicular to the specimen face during the test, causing the paper to tear along the pre-cut. The magnitude of the tearing force is determined by measuring the energy expended by the pendulum during the tearing process, i.e., the work done.

In terms of operational details, the instrument requires a pre-cut treatment of the specimen prior to use to ensure that the tear occurs in the intended location. The specimen should be clamped in such a way that it should be evenly clamped to avoid errors during the test. The adjustment mechanism includes level adjustment and friction adjustment to ensure that the instrument is in the correct operating state and that the measurement results are accurate and reliable. During the adjustment process, the horizontal position of the pendulum, the alignment of the clamping mechanism, and the zero calibration of the pointer need to be checked to ensure the accuracy of the measurement.

Instrument calibration

1. Ensure that there is no bending of the pendulum shaft, and the clamp spacing is accurate (2.8 ± 0.3) mm to ensure the clamping stability of the specimen and the accuracy of the tear test.

2. Check whether the knife is firmly installed and the blade is sharp and undamaged, and ensure that the incision is neat and located in the center of the clip to ensure the accuracy of the tear.

3. Check whether the pointer is undamaged and make sure that its reading on the dial is accurate. Adjust the dial position to calibrate the readings and ensure reliable measurement results.

4. After adjusting the level, observe whether the pointer points to the zero point when the sample is not clamped. If not, move the pointer stopper to adjust.

5. Make a reference mark on the stop device of the pendulum to ensure that the friction control of the pendulum when swinging is within the specified range. Test the number of movements of the pendulum to ensure that the swing is smooth and the friction meets the standard.

6. Clean or adjust the pointer and its bearing to ensure that the pointer will not be disturbed by too much friction during the measurement process, which will affect the accuracy of the reading. After adjusting the friction of the pointer, the zero point needs to be recalibrated.

7. Cut the sample with 80~100 g/m² crisp paper, ensure that the incision length of the torn specimen is (43 ± 0.5) mm, and adjust the position of the knife to ensure the accuracy of the incision.

8. Use a special weight to calibrate the instrument ruler, place different weights on the screw hole of the pendulum, and measure the rise of the pendulum to calibrate the scale of the instrument.

Experimental Procedure

Experiment preparation

(1) Sampling - select the appropriate specification of the paper sample, and carry out the necessary pretreatment to ensure that it meets the test requirements.

(2) Constant temperature and humidity treatment - the paper sample is treated with constant temperature and humidity to ensure the consistency and accuracy of the test environment.

(3) Sample size and quantity requirements - cut the sample according to the standard requirements to ensure that the size and quantity meet the test specifications.

Test Steps

(1) Instrument adjustment

Adjust the horizontal state of the instrument to ensure that the instrument is placed smoothly.

Check the balance of the pendulum to make sure it swings properly.

Calibrate the zero point of the pointer to ensure that it is accurate.

Adjust the friction control to ensure that the friction is within the specified range when swinging.

(2) Specimen preparation and clamping

Handle the specimen incision to ensure that the incision length meets the standard requirements.

The specimen is accurately clamped in the clamping mechanism to ensure stable clamping.

(3) Tear test

Perform a tear test, read and record a reading or digital display of the pointer.

Ensure that the specimen tear line during the tear process is accurate and unbiased.

(4) Calculation of results

Internal tear calculation –The internal tear is calculated using a formula.

Tear Index Calculation –The tear index is calculated using a formula.

The determination of paper tear is not only an important part of evaluating the quality of paper materials, but also a key step to ensure the stable performance of the product in practical applications. By using an Allimendorf Single Tear Meter, we are able to accurately measure the tearing capacity of the paper, providing reliable data support for production and quality control. Standardized experimental preparation and testing procedures ensure the accuracy of the measurement results, while detailed result calculations provide the basis for further analysis and application.