The technical research of foundation liquid in laboratory film proofing and performance testing is a crucial part of cosmetics research and development. The main purpose of film proofing is to simulate the performance of liquid foundation on the skin to evaluate its performance such as coverage, durability, gloss, and color reproduction, so as to provide a scientific basis for the development and optimization of subsequent products. This article will discuss in detail the process flow, performance testing methods and key technical points of liquid foundation in the laboratory, so as to provide systematic guidance for the research and development of liquid foundation products.

1. The significance of liquid foundation film proofing

Lab-made film proofing is an essential step in the development of liquid foundation. By applying a sample of the liquid foundation to the substrate, it is possible to simulate its application effect on real skin and observe its film-forming properties, hiding power, coating uniformity, etc. This process provides developers with an in-depth understanding of the properties of the foundation and provides an important reference for subsequent formulation and process adjustments. At the same time, film proofing also provides reliable samples for performance testing, laying the foundation for various tests such as concealment, water resistance, oil resistance, oxidation resistance, etc.

Second, the process of foundation liquid film proofing

In the laboratory, the proofing of foundation liquid film usually includes steps such as substrate selection, film coating method, coating parameter setting, and film forming condition control. The following is the detailed process flow:

1. Substrate selection

The substrate for making the film is usually a material with similar properties to human skin, such as glass sheets, plastic films, or artificial skin models. For the performance evaluation of liquid foundation, the substrate should be selected with a certain adsorption capacity to simulate the real performance of liquid foundation on the skin. Common substrate materials include silicone skin, transparent plastic sheet, PVC film, etc., which have the characteristics of high flatness and easy cleaning, and are suitable for multiple coating experiments.

2. Coating method

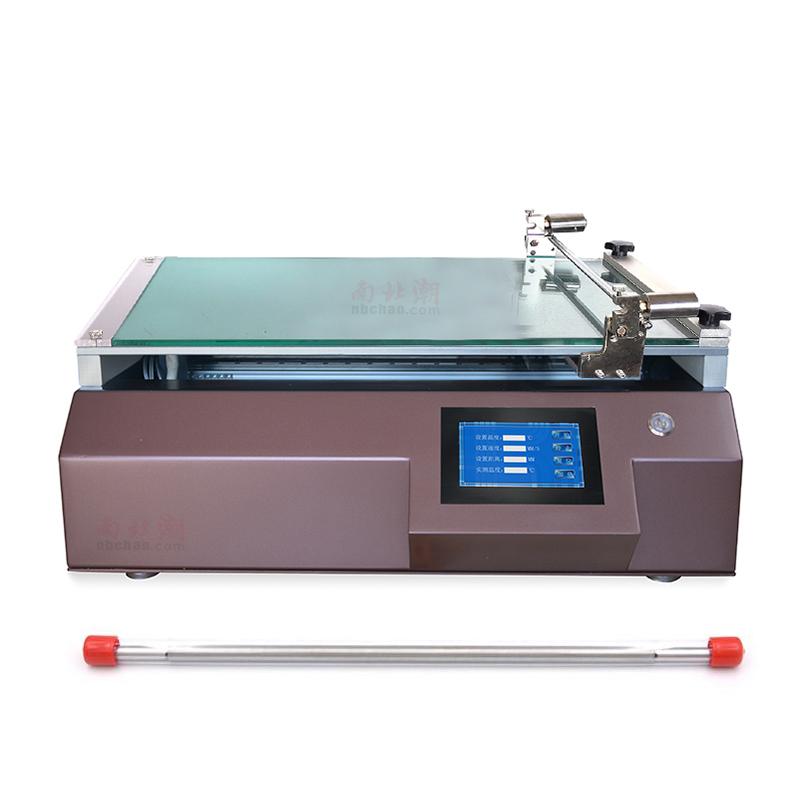

The choice of coating method directly affects the film-forming effect and the accuracy of performance testing of foundation liquid. Commonly used coating methods in laboratories include manual coating, automatic coater coating, etc. Manual coating is suitable for coating experiments with a small number of samples, and the operation is flexible, but the uniformity of the coating film is average. Electric coating is a more commonly used method in laboratory proofing by adjusting the gap between the scrapers or replacing the wire rods with different wire diameters to obtain a uniform and controllable film thickness.

During mechanical coating, the type and gap of the coating knives have a significant impact on the uniformity and thickness of the coating. Commonly used coating knives include wire rods, scrapers, etc. Wire rod coating is suitable for the preparation of thinner film layers, while scraper coating is suitable for coating experiments of thicker film layers, and the coating film thickness can be adjusted.

3. Coating film parameter setting

Coating parameters include coating speed, coating thickness, coating temperature, etc. The coating speed is usually set between 10-30 mm/sec to ensure a uniform coating film. The thickness of the application varies depending on the coverage and user experience of the liquid foundation, and is usually between 50-150 microns. The coating temperature should be maintained at room temperature (20-25°C) to avoid too high or too low temperature affecting the fluidity and film-forming properties of the foundation.

4. Control of film-forming conditions

After the coating is completed, the sample needs to be dried and film-formed under suitable conditions. Temperature, humidity and drying time are the key factors that affect the quality of the film during film formation. Normally, the film-forming drying of the liquid foundation is carried out in an environment with a relative humidity of 50-60% and a temperature of about 25°C. The drying time depends on the thickness of the film and the formula of the foundation, but is generally 15-30 minutes. Once sufficient dryness has been ensured, subsequent performance tests can be carried out.

3. Test method for the performance of foundation liquid

After the proofing is completed, the performance of the liquid foundation is tested as an important step to evaluate its efficacy. Common tests include coverage, durability, water resistance, oil resistance, adhesion, and skin compatibility. The following is a detailed description of the main performance testing methods:

1. Concealment detection

Coverage is one of the important evaluation indicators of liquid foundation, which determines the product's ability to cover skin imperfections. Concealment is usually tested with a reflectance light meter. The liquid foundation is evenly applied to the substrate and the intensity of the reflected light of the film is measured with a reflectance light meter. The higher the coverage, the lower the intensity of the reflected light. By comparing it to standard coverage, you can quantify the coverage of your liquid foundation.

2. Persistence detection

Durability is a key performance of a liquid foundation that can hold makeup for a long time. Artificial sweat and sebum simulants are commonly used in laboratories to test the durability of coated film samples. The coating samples were placed in artificial sweat or sebum mimics and kept at a constant temperature in an Incubator, and the state of the coating after a certain period of time was recorded, and the durability of the foundation was evaluated by comparing the changes in the coating before and after.

3. Water resistance and oil resistance testing

Water and oil resistance are important indicators for evaluating how a liquid foundation performs in a humid environment or on oily skin. Water resistance testing typically involves soaking a sample in water for a period of time to see if the coating dissolves, foams, or changes color. For oil resistance, artificial sebum is applied to the surface of the film to observe its absorption and film integrity to evaluate the oil resistance of the foundation.

4. Adhesion testing

Adhesion is a key property in the stable adhesion of liquid foundation to the skin. Laboratories typically use the scribing method for adhesion testing. The adhered texture of the coated film is evaluated by observing the peeling of the liquid foundation by drawing a certain size on the surface with a scratcher, and then taping it on the scratch and quickly peeling it off. The smaller the shedding area, the better the adhesion.

5. Gloss and color reproduction detection

The gloss and color reproduction of the liquid foundation are important factors that affect the effect of makeup. Gloss testing uses a gloss meter to measure the reflection of light from the surface of a coating film. The color reproduction test uses a Colorimeter to measure the color difference value of the coating film sample, and compares it with the standard Color Chart to judge the color stability and reduction degree of the foundation liquid.

6. Skin compatibility test

As a product that comes into direct contact with the skin, the safety and skin compatibility of liquid foundation are crucial. Laboratories typically use artificial skin or cultured skin cells for compatibility testing. The irritation and sensitization to the skin were evaluated by observing the changes of the coating film sample after contact with the artificial skin. This test is effective in reducing the risk of irritation on sensitive skin.

Fourth, the key technical points of foundation liquid film making and performance testing

Uniformity of film making——In the process of film making and proofing, a uniform film layer is the premise to ensure the accuracy of subsequent performance testing. Attention should be paid to the precise control of the coating speed and tool clearance, and the appropriate substrate should be selected to achieve a good film-making effect.

environmental control——The coating and drying process needs to be carried out under constant temperature and humidity conditions to avoid the influence of external environmental factors on the performance of the foundation. It is recommended to complete the entire proofing and testing process in a constant temperature and humidity laboratory.

Data logging and analysis——In the process of performance testing, the parameters and results of each test should be recorded in detail, data analysis should be carried out, and the relationship model between the performance of the liquid foundation and the formula and film making process should be established, so as to provide data support for subsequent product optimization.

V. Conclusions

Film proofing and performance testing of liquid foundation in the laboratory are indispensable and important links in the research and development of cosmetics. Through the precise film-making process and comprehensive performance testing, R&D personnel can fully understand the performance of liquid foundations, thus providing a scientific basis for formulation adjustments and product improvements. The uniformity of film making, the standardization of testing methods and environmental control are the key elements of film proofing and performance testing. Through systematic research and testing, we can effectively improve the quality and market competitiveness of liquid foundation, and meet consumers' needs for high-quality and diversified cosmetics.