introduction

Due to their excellent optoelectronic properties, metal halide perovskite materials have gradually become an important part of modern optoelectronic devices, especially in applications such as X-ray Detectors. The preparation of perovskite films is a key link to realize its application, and the rotary coater, as an efficient and uniform film preparation technology, plays an important role in the production of perovskite films. In this paper, we will discuss the application of rotary coater in the preparation of metal halide perovskite composite films, analyze the advantages and disadvantages of different preparation methods, and discuss the current challenges.

Overview of preparation methods for perovskite films

The preparation methods of perovskite films mainly include the following:

Direct deposition——Perovskite materials are deposited directly on the substrate. Although this method can form a complete film, it is greatly affected by the external environment, resulting in poor stability.

Polymer encapsulation –Perovskite powders or nanocrystals are encapsulated in a polymer matrix, such as PMMA or PDMS. This method can effectively improve the stability of perovskites, but it may lead to agglomeration, affecting the uniformity and transparency of the film.

Grown in situ——In-situ precipitation of perovskites in polymers or other substrates avoids agglomeration effects and improves the stability of the material.

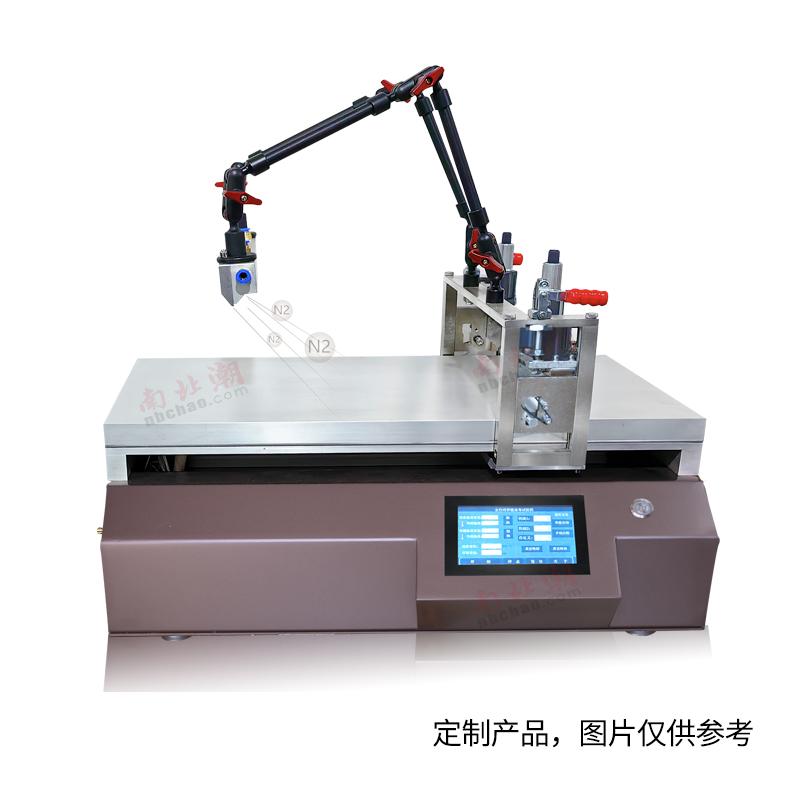

The working principle of the rotary Film Applicator

The rotary coater uses centrifugal force to form a uniform film on the surface of the substrate by evenly coating the solution on the substrate. The basic workflow consists of placing the solution to be coated in the center of the substrate, starting the machine, the substrate rotates at high speed, and the solution expands outward under the action of centrifugal force, finally forming a uniform coating on the surface of the substrate.

Advantages of rotary Film Applicators

Uniformity – The rotary film coater can form a film with uniform thickness in a short time, which greatly improves the repeatability of film formation.

adaptability——It is suitable for many types of solutions, including aqueous, solvent-based and high-viscosity liquids, and adapts to different perovskite precursor materials.

High efficiency——The speed of spin coating technology can significantly increase production efficiency and is suitable for large-scale industrial applications.

Preparation of CsPbBr3 nanocrystals and their application in thin films

In the preparation of perovskite films, the synthesis of CsPbBr3 nanocrystals is one of the key steps. The preparation process mainly includes the following steps:

1) Preparation of Cs-OA precursor solution: Cs2CO3 is reacted with oleic acid and other compounds through high-temperature reaction to obtain Cs-OA precursor solution.

2)Dissolution of PbBr2: PbBr2 is dissolved in an organic solvent to form a precursor that can be used in subsequent reactions.

3)Thermal injection synthesis: Cs-OA precursor solution is rapidly injected into PbBr2 solution to promote the formation of perovskites through temperature changes.

This method not only improves the quality of nanocrystals, but also lays the foundation for the uniformity and performance of subsequent films.

Encapsulation and preparation of CsPbBr3@PMMA composite films

Rotary coaters also play an important role in the preparation of CsPbBr3@PMMA laminated films. The specific process includes:

1)Dissolution of PMMA: PMMA particles are added to the organic solvent and heated and stirred to form a homogeneous colloidal liquid.

2)Addition of nanocrystals: CsPbBr3 nanocrystals synthesized by thermal injection method were added to the PMMA gel and mixed well to ensure uniform dispersion.

3)Spin coating: The mixed solution is spin coated onto a glass substrate, a film is formed by a rotary film coater, and the residual solvent is removed in a vacuum oven.

4)Curing treatment: After the film is cured, the CsPbBr3@PMMA composite film formed has good stability and light transmittance, which is suitable for the scintillator of X-ray Detectors.

Advantages of the in situ growth method

In situ growth is an emerging perovskite film preparation strategy, and its main advantages are:

By controlling the reaction conditions, the agglomeration of perovskite particles can be effectively avoided and the uniformity of the film can be ensured.

The in-situ growth method can achieve uniform precipitation of perovskites, which can significantly improve the stability of the film and reduce the influence of the external environment on the performance of the film.

Regulating the precipitation process of perovskite in the matrix material can optimize the optoelectronic properties of the film according to the needs and improve the performance of the final device.

Current challenges and future prospects

Although the rotary coater has shown many advantages in the preparation of perovskite films, it still faces some challenges:

Material agglomeration – In the polymer matrix, the agglomeration of perovskite particles still exists, affecting the uniformity and transparency of the film.

Environmental stability——Perovskite materials are sensitive to air and moisture, and effective measures should be taken to enhance their environmental stability during the preparation process.

Process control——The control of precursor concentration, rotation speed and time needs to be refined to ensure the thickness and uniformity of the film.

In the future, with the emergence of new materials and the continuous optimization of the preparation process, the application of rotary coating machine in the preparation of perovskite films will be more extensive, and related research will also provide strong support for the performance improvement of optoelectronic devices.

conclusion

As an efficient film preparation tool, the rotary coater has shown important application potential in the preparation of metal halide perovskite composite films. Through the analysis of different preparation methods, combined with their advantages and challenges in practical applications, the rotary coater will continue to play a key role in future research and industrial applications, opening up new possibilities for the application prospects of perovskite materials.

References

Preparation and Properties of CsPbBr3 Perovskite Composite Scintillators-CHEN Weiqing