Tensile Tester is actually a kind of testing machine, which is an indispensable instrument and equipment in the laboratory testing process. It is widely used in the quality testing of plastics, pipes, wires and cables, fibers, films and other products. However, due to operational problems or other factors during use, some faults will inevitably occur. For this reason, this article mainly analyzes and introduces some common faults and causes and countermeasures of Tensile Testing Machines in daily testing applications.

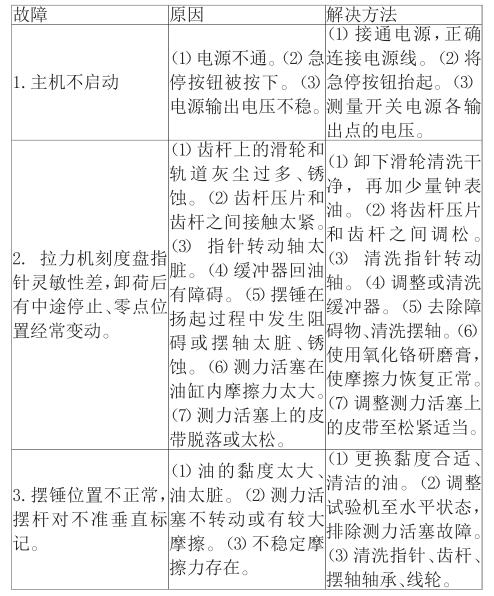

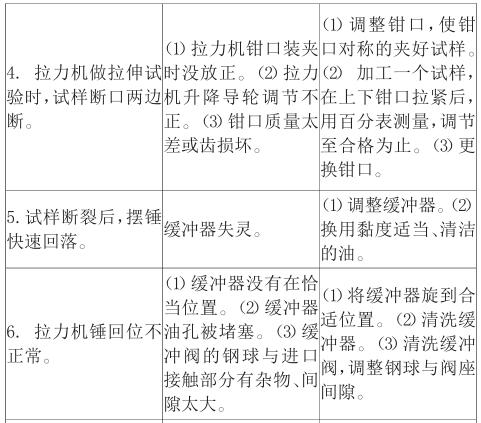

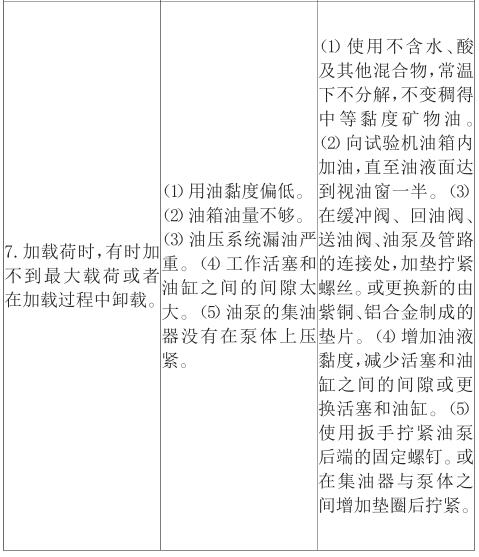

Tensile Tester is a kind of experimental machine, which is the required testing equipment in the process of material development, physical property experiment, education and teaching, quality control, material inspection, random inspection of production line, etc. It is used to test the mechanical functions of materials such as tension, compression, bending, shearing, and peeling. In the process of using the tension machine, some failures will inevitably occur. We should be able to find and judge these failures and solve them correctly. Only in this way can the various problems that arise during the use of the tensile machine be successfully resolved, the service life of the tensile machine can be extended, and the experimental results can be more accurate. The various problems that the author often encounters during use have been solved and summarized as follows:

Paying attention to the daily maintenance of the Tensile Testing Machine can reduce the occurrence of failures. Always check whether the frame of the testing machine is lubricated, check the load system, strain system, and transmission system of the testing machine, check the functions of the control panel, power supply voltage, power-on detection, pneumatic clamps, Air Compressor pumps, and foot switches. Frequent daily maintenance can avoid erroneous results during testing and prolong the service life of the tensile machine. Regularly check and calibrate the testing machine to ensure the normal use of the testing machine.