In this paper, for 7 different specifications of 21-6-9 stainless steel pipes and 3 different specifications of 321 stainless steel pipes, arc samples or pipe section samples are used, and the basic mechanical properties parameters of the materials are obtained based on unidirectional tensile tests, which provides a reference for the plastic forming analysis of the above-mentioned stainless steel pipes.

The basic mechanical property parameters of 7 specifications of 21-6-9 stainless steel pipe and 3 specifications of 321 stainless steel pipe were obtained by unidirectional tensile test, and the 21-6-9 stainless steel pipe has high strength and poor plasticity, and its mechanical property characteristics are not conducive to plastic forming such as drawing and bending. Compared with 21-6-9 stainless steel pipe, 321 stainless steel pipe has low strength and good plasticity. The mechanical property parameters of the 21-6-9 stainless steel pipe with a thickness of Φ1.25 mm × 0.02 mm were obtained through the tensile test of the arc specimen and the tensile test of the pipe specimen, respectively, and it was found that the elongation obtained by the pipe section specimen was greater than that obtained by the arc specimen, and its yield strength and tensile strength were slightly smaller than the yield strength and tensile strength obtained by the arc specimen. Since the curved specimen is not subjected to a unidirectional stress state during the stretching process, the results obtained for the pipe section specimen are more accurate.

Plastic processing of pipes is easy to meet the requirements of lightweight, toughening, low-consumption, effective and accurate manufacturing of plastic forming products, and has become an important direction of research and development of professional plastic processing technology in the 21st century [1]. Pipe parts are widely used in industrial sectors such as aerospace, automotive, petrochemical, light industry, and transportation [2]. In recent years, with the development of thin-walled pipe processing technology, thin-walled stainless steel pipes have developed rapidly because the strength of thin-walled stainless steel pipes is higher than that of thin-walled aluminum alloy pipes, and the price is lower than that of thin-walled titanium alloy pipes.

The in-depth study of the plastic forming characteristics and deformation laws of pipes needs to be based on accurately obtaining the mechanical property parameters of the materials. However, at present, most of the research on material properties focuses on plates, and there are few studies on the mechanical properties of pipes. Due to the different production processes, there are differences in the basic mechanical properties of pipes and plates. It is found that when the profile material is the same, the thickness and cross-sectional shape are different, the basic mechanical properties are also quite different. The performance of heat treatment varies more [3-4]. Therefore, in order to obtain accurate data on the mechanical properties of materials, in-depth experimental studies are required on specific specifications of pipes.

1. Sample preparation and test methods

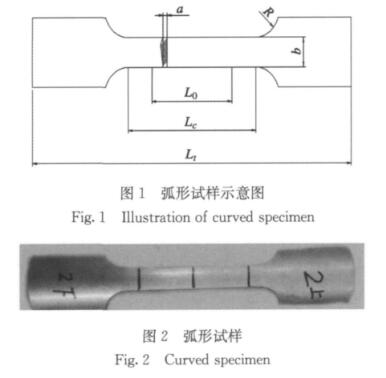

According to the national standard GB/T228-2002 [5], when the outer diameter of the pipe is D<30mm, the pipe section sample is used; When the outer diameter of the tube is D≥30mm, a longitudinal arc specimen is used. In order to compare the influence of the shape of the sample on the mechanical properties of the pipe material for the 21-6-9 pipe with a thickness of Φ1.25mm ×0.02mm, two shapes were used. The arc-shaped specimen is directly intercepted from the pipe by wire cutting, and the specimen is used

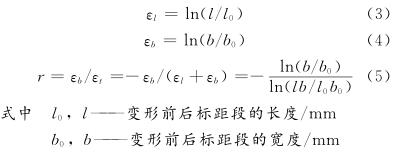

As shown in Figure 1, the real specimen is shown in Figure 2. The specimen of the pipe section is cut from the pipe by wire cutting, and each specimen needs to be equipped with two pipe plugs to prevent the specimen from being pinched. The schematic diagram of the sample and the tube plug is shown in Figure 3, and the real sample and tube plug are shown in Figure 4. Three samples of each type were taken, and the test results were taken as the average of the three groups of tests.

The tensile test is carried out on the new Sansi CMT5205 electronic multi-function testing machine with a maximum load of 200kN. The tensile force is measured by the automatic signal acquisition system that comes with the CMT5205 materials testing machine. The axial displacement is obtained by a longitudinal extensometer, model YSJ-50/25-ZC, gauge distance 50mm, measuring range 25mm. The lateral displacement is obtained by a transverse extensometer, the model is YSJ-25/3-ZC, the maximum gauge is 25mm, and the minimum gauge is 3mm. The test speed was set to 3mm/min.

1.2 Measurement of plastic strain ratio

The sheet metal is in different directions (along the rolling direction, perpendicular to the rollingdirection and thickness) exhibit different flow characteristics. The different flow characteristics of the sheet in the plane are called planar anisotropy [6]. The anisotropy in all directions is expressed by the plastic strain ratio r, which is the ratio of the true strain in the width direction to the true strain in the thick direction when the specimen is stretched along the axial direction to produce uniform plastic deformation, that is, r=εb/εt(1)

In general, the thickness of the sheet is relatively small, and the amount of variation is obtainedIt is difficult to measure accurately, so the volume invariant condition, εl+εb+εt=0, replaces εt, and converts it into:

r=εb/εt=-εb/(εb+εl)(2)

where εl ——— the longitudinal strain of a unidirectional tensile specimen

εb ——— transverse strain of a unidirectional tensile specimen

εt ——— thick strain of a unidirectional tensile specimen

When r=1, it is an isotropic material, and the smaller the r value, it is described

The lower the strength in the direction of sheet thickness, the easier it is to thin the wall thickness when drawing or bending, which is not conducive to forming, so it is generally desirable for the material to have a higher r value. In this paper, the thick anisotropic behavior of materials in the length direction is studied.

1.2.1 Measurement of plastic strain ratio of arc-shaped specimens

At present, the measurement of the plastic strain ratio of materials is mainly for plates

The width of the gauge section of the arc-shaped specimen is relatively small relative to the diameter of the pipe, so it can be approximately regarded as a thin plate, and the plastic strain ratio of the arc-shaped specimen is measured according to GB/T5027-1999 [10]. The r value of the material generally changes significantly with the different deformation, and for steel, aluminum and other metals, it is characterized by the r value when the engineering strain is 15% or 20%. The specimen is statically stretched on the testing machine at a speed of 3 mm/min, and the deformation of the gauge in the length and width direction is tracked using two extensometers, longitudinal and transverse. According to Eq. (3) ~ Eq. (5), the plastic strain ratio at different times is calculated.

1.2.2 Measurement of plastic strain ratio of pipe section specimens

For pipes with small diameters, try if the pipes are cut into arcs

Due to the large curvature, the r-value measurement according to the measurement method of the plastic strain ratio of the thin plate will inevitably bring a large error. Therefore, it is necessary to calculate the plastic strain ratio of the pipe section specimen according to the following formula, statically stretch the specimen on the testing machine at a speed of 3mm/min, and use two extensometers in the longitudinal and transverse directions to track and record the deformation of the length and diameter direction of the gauge distance.

In the uniform plastic deformation stage, according to the principle of volume invariance, there are:

2Results and Discussion

2.121-6-9 Basic mechanical properties of pipes

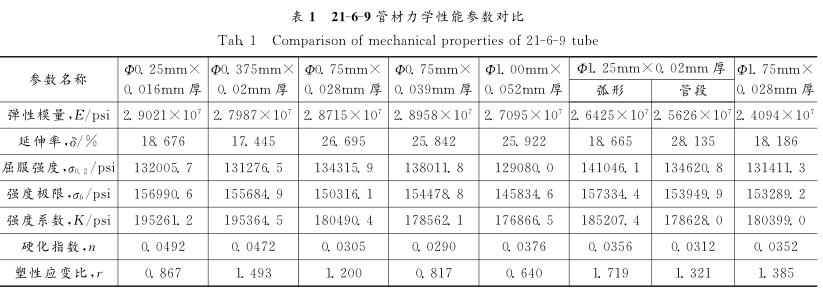

Different specifications of 21-6-9 stainless steel pipes determined by tensile testThe mechanical property parameters are shown in Table 1, and the nominal stress-strain curve and the real stress-strain curve are shown in Figure 5 and Figure 6 respectively. As can be seen from Table 1, there are differences in the tensile mechanical properties of 21-6-9 stainless steel pipes of different specifications at room temperature. The elastic modulus and elongation of the material vary greatly, with the minimum elastic modulus being 2.4094×107psi and the maximum being 2.9021×107psi. The minimum elongation is 17.4451%, the maximum is 28.1354%, for the pipe with a thickness of Φ1.25mm × 0.02mm thick specification, the elongation obtained by the pipe section sample is much greater than the result of the arc sample, this is because the clamping end needs to be clamped flat before the arc sample is stretched, and the specimen is not strictly in a one-way tensile stress state during the stretching process, therefore, the result obtained by the pipe section sample is more reasonable than that of the arc sample. The yield strength σ0.2 and strength limit σb of the material change slightly, and the strength of the material in 21-6-9 is larger, reaching more than 130000psi before yielding, but the necking phenomenon occurs soon after the material yields, that is, the difference between the strength limit and the yield strength is small, which is also manifested in the fact that the curve of the uniform plastic deformation part on the real stress-strain curve of the material is shorter, the curve of the material after yield is flat, and the material hardening index obtained by formula fitting is smaller. In summary, it is found that this characteristic of the material is not conducive to the drawing or bending deformation of the pipe, due to the large strength of the material, the deformation force required for the deformation of the pipe is larger, but the stress change space allowed by the uniform plastic deformation of the material is small, and the pipe is easy to crack.

The r-value of a material is generally characterized by the r-value at 15% or 20% engineering strain. However, for 21-6-9 stainless steel pipes, due to the short uniform plastic deformation stage of the pipe, the material will be necked when the engineering strain is less than 0.1, and the stress-strain curve of the material after necking can no longer correctly express the plastic deformation capacity of the material, so it is necessary to take the midpoint of the nominal stress-strain uniform plastic deformation stage to calculate the plastic strain ratio.

As shown in Table 1, the plastic strain ratios of 21-6-9 pipes of different specifications are quite different, and the plastic strain ratios of Φ0.25mm×0.016mm thick, Φ0.75mm×0.039mm thick, and Φ1.00mm×0.052mm thick are 0.8667, 0.8167 and 0.6388 respectively.

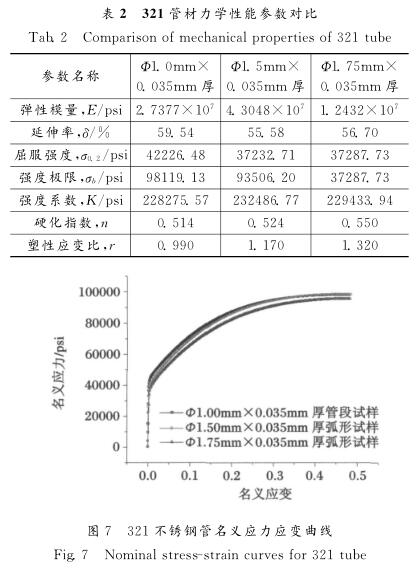

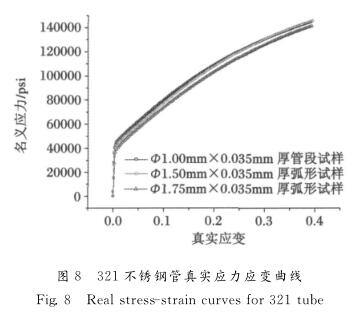

2.2 The basic mechanical properties of 321 pipes are determined by tensile tests and the mechanical properties parameters of 321 stainless steel pipes of different specifications are shown in Table 2, and the nominal stress-strain curve and real stress-strain curve are shown in Figure 7 and Figure 8 respectively. It can be seen that the mechanical property parameters of 321 pipes of different specifications are similar. Compared with Table 1 and Table 2, compared with 21-6-9 material, 321 material has smaller yield strength, higher elongation and hardening index, which is conducive to the plastic forming of pipes. The yield strength is small, the force required for pipe forming is small, the hardening index is large, the space for uniform plastic deformation of the material is large, and the plastic deformation is easy; At the same time, the high elongation also indicates that the pipe has good plasticity and is not easy to break.

3 Conclusion

1) The mechanical property parameters such as elastic modulus, yield strength, tensile strength, elongation, strength coefficient, hardening index and plastic strain ratio of 7 specifications of 21-6-9 stainless steel pipes were obtained, and it was found that 21-6-9 stainless steel pipes had high strength, poor plasticity, and mechanical property characteristics were not conducive to plastic forming of deep drawing and bending.

2) Obtain the mechanical property parameters such as elastic modulus, yield strength, tensile strength, elongation, strength coefficient, hardening index and plastic strain ratio of 321 stainless steel pipes of 3 specifications, compared with 21-6-9 stainless steel pipes, 321 stainless steel pipes have low strength and good plasticity.

3) The mechanical property parameters of 21-6-9 stainless steel pipes with a thickness of Φ1.25mm ×0.02mm were obtained through the tensile tests of the arc specimen and the pipe section specimen, respectively, and it was found that the elongation obtained through the pipe section specimen was greater than that obtained by the arc specimen, and the yield strength and tensile strength were slightly smaller than the yield strength and tensile strength obtained by the arc specimen.