With the rapid development of the steel wire rope market economy, in recent years, the products have entered the international market. The steel wire rope for the whole rope breaking tensile test has been paid more and more attention. All the steel ropes developed for oil wells are required to be tested for the breaking force of the whole rope.

This article is mainly aimed at the practical application of production and testing of this kind of steel wire, the scientificity of testing the breaking force of the whole rope, the tensile strength of the steel wire, the uniformity of twisting, the uniformity of knots, the material of the rope core and the clamping method during the test. The influence of the breaking force of the wire rope is analyzed and introduced.

At present, most of the steel wire ropes produced in my country implement the GB11o2-74 standard. The steel rope only needs to be split and tested to check the bending, torsion, tensile strength and the sum of the breaking force of the steel wires in the steel rope. This test can only be done when the user requires the whole, rope breaking tensile test, and it is agreed by both parties and indicated on the order. (Related instrument: Tensile testing machine)

Judging from the current situation of the testing equipment of the steel rope manufacturers, most manufacturers do not have the Tensile Testing Machine for the breaking force of the whole rope, so the current steel wire ropes in our country are rarely tested for the breaking force of the whole rope.

1 The scientificity of testing the breaking force of steel wires

(1) The stress state during the breaking tension test of the whole rope is the same as that of the steel rope when it is working.

When the steel rope is lifted or pulled, it mainly bears the tension load.

When the steel wire rope is used for the whole rope breaking tensile test, the sample is clamped on the Tensile Testing Machine, tension is applied, and the force applied when it breaks is measured. Therefore, the stress state of the steel wire rope is the same in the test and in use.

(2) The breaking force of the wire rope can comprehensively reflect the production level of the wire rope.

The quality of the steel wire rope mainly depends on the quality of the steel wire for making the rope and the twisting quality of the twisted strands and ropes. Testing the breaking force of the whole group can not only show the tensile strength and toughness of the steel wire, which is the component of the steel wire rope, but also reflect whether the wire rope is twisted evenly.

The demolition test of the copper wire rope can only reflect the mechanical properties of the steel wire used for the rope. In the actual production test, according to the results of splitting test, the tensile strength, bending, torsion and breaking force of the steel wire in the rope all meet the standard, and some steel wire ropes are judged as special ropes. However, the breaking force test of the whole rope is not unqualified products. Tracing it to its cause is that the strand splitting test cannot reflect the twisting quality when twisting strands and closing ropes when producing steel ropes.

The whole rope breaking tensile test of the steel wire rope requires the production plant's production technology and operation level to a higher level. Only when the installation, management and worker operation are improved to a certain level can the qualified rate of the breaking force of the wire rope be improved.

2 Factors affecting the breaking force of steel wire

2.1 Tensile strength of steel wire in steel wire rope

The tensile strength of the steel wire in the wire rope directly affects the breaking force of the steel wire rope. This shows the relationship between the two no matter from the standard requirements or the measured data.

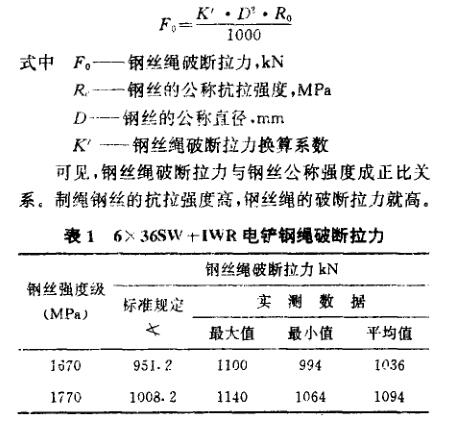

In foreign standards and domestic GB8918-88 standards, standard. The breaking force of the wire rope is calculated according to the following formula:

Table 1 lists the actual measured statistical data of the 6x36SW ten IWR electric shovel steel wire fan produced by our company. These data show that the breaking force of the steel wire rope is affected by the strength of the steel wire whether it is the maximum value, the minimum value or the average value.

2.2 Uniformity of initial production of steel wire

When the steel wire rope is twisted and closed, the tension of the steel wire or strands, whether the tension is uniform or not, has a great influence on the breaking force of the whole rope when the steel is empty. If the tension is not uniformly controlled, the tension of the steel wires in the strands or the strands in the rope will be inconsistent. Or the steel wire breaks first because it exceeds its ultimate strength, resulting in a low test value.

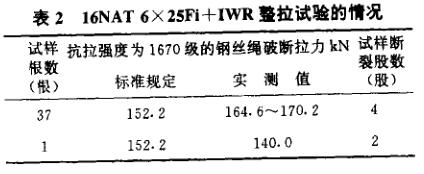

In the early stage of organizing the production of steel ropes for export, the company carried out comparative and analytical research on the breaking force test of steel wire ropes, found out the existing problems, continuously improved the twisting quality in production, and gradually improved the uniformity of twisting strands and 3-way joints. To improve the breaking force of the wire rope. The influence of twist uniformity on the breaking force of the steel rope is shown in Table 2

It can be seen from Table 2 that when the breaking force test of the whole rope is carried out, the broken strands of the steel rope sample are less, because the loads borne by each strand are different, and some strands with a large load break first, resulting in the measured value of the breaking force of the whole rope. , does not meet the standard requirements, and this rope is a special rope that meets the strength level of 1670MPa during the split test. If the number of broken strands is large, the breaking force of the whole rope is higher, and all of them meet the standard requirements.

2.3 The material of steel wire core

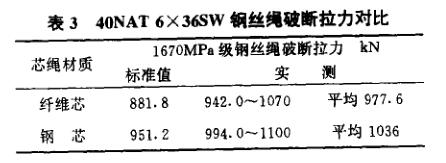

The rope core of the steel wire rope is mainly divided into two categories: fiber core and metal rope core. The metal rope core is a strand or rope made of steel wire as the rope core. The data in Table 3 shows that for steel wire ropes with the same structure and diameter, the core rope with a metal core can increase the breaking force of the steel wire rope.

2.4 Structure of steel silk

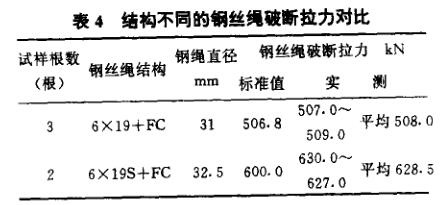

It is known that the structure of the wire rope is also one of the main factors affecting the breaking force of the steel rope. Since the steel wires in the layers of the point contact wire rope are twisted non-parallel, the steel wires between the layers are in point contact. When the steel rope is stressed, The contact stress between the steel wires is very large; while the line-contact steel rope is twisted in parallel, the steel wires in the same layer and between layers are in a parallel state, and they are closely attached to each other in line contact. When the steel rope is stressed, the contact stress between the steel wires is much smaller, and the filling coefficient of the line contact steel wire rope is larger than that of the point contact steel rope, so the effective bearing area is larger when the force is applied, and the load bearing capacity is larger than that of the point contact steel rope. The rope is large. Usually, the breaking force of the whole rope of the interlining line contact steel rope is more than 8% higher than that of the point contact 6x19 copper rope, and the breaking force of the filled line contact steel rope is 10% higher than that of the point contact 6)<19 collar rope.

The whole tension test data of steel ropes with similar diameters of 6x19+FC and 6x19S+FC produced by our company are listed in Table 4. Compared with the two, the breaking force of the wire contact steel rope 32.5NAT6X19S+FC is 23.7% higher than that of 31NAT6X19+FC .

2.5 Clamping method of wire rope breaking tensile test

There are two ways to hold the steel wire rope for the breaking tensile test: the pouring socket method and the mechanical clamping method.

The cast socket pull test is to spread the steel wires at both ends of the steel wire rope sample to form a trumpet-shaped brush head. After cleaning the oil, put it into a conical mold cover, and combine the molten alloy with the wire rope brush head to form a whole after being injected and condensed.

Mechanical clamping is to directly clamp the steel wire rope sample on the mechanical tool installed on the testing machine for the whole rope tensile test.

Using these two solid methods to test, by comparison, most of the fractures of the steel rope in the test using mechanical fixtures occur at the tangent point between the steel rope and the central sample wheel. The measured breaking force of the whole rope is 4~10kN lower.

3 Conclusion

(1) The breaking force test of the steel wire rope comprehensively reflects the quality level and service life of the steel wire rope.

(2) The development and promotion of the use of line contact wire rope and steel core wire rope can improve the breaking force and service life of wire rope, and give full play to the use potential of effective steel.

(3) The casting socket method is used as the breaking force test of the steel wire 1 rope, which can accurately measure the breaking force of the steel wire rope.