With the continuous development of the market economy, the tension testing machine should be more and more extensive, and the safety of the Tensile Testing Machine has also received more and more attention. In the process of use, due to improper operation or the influence of various factors, it is inevitable that there will be some fault problems or errors.What safety issues should be paid attention to in the Tensile Testing Machine and how to maintain it? This article describes the following.

Based on the above reasons, the maintenance work is summarized as follows:

(1) Maintenance system 1 for the maintenance of the assumption of work.

(2) The method and period of inspection are related to the method and period of the first period to give reliable and effective assurance to the user.

(3) Repair 1 is related to the difference in the judgment of the manufacturer in the maintenance and manufacturing unit at the time of repair.

(4) About the safety device - the safety device of the Tensile Testing Machine; The safety device of the load should be guaranteed to work within 1.5 times of the maximum load. In addition, the safety device that allows the range of motion automatically sounds an alarm when the limit position is reached. The above devices are limited to the main unit.

(5) The use of the matter is declared as a tensile test

machine, the stretching speed, needs to be certain. However, if the tensile speed is unstable, it should be judged and solved.

In view of the above points, the following is a statement.

1. Assumptions for maintenance work

The current division of work of the testing machineTest 1 was carried out by the Inspection Division. In addition, the inspection department is also responsible for the purchase and disposal of chucks that have been severely worn out during the inspection work.

The maintenance work is carried out by the Metering and Maintenance Section. Responsible for the installation of the testing machine to the daily test work, without failure, in order to ensure the accuracy of the testing machine for the user.

At the initial stage of setting up the testing machine, the Inspection Division will manage the testing machine in one package. However, partial inspections, inspections, and repairs also depend on the manufacturer (and maintenance unit). As the situation evolved, maintenance techniques were improved, and the planning of the maintenance work system was carried out so that the requirements for the most appropriate maintenance to be carried out effectively were achieved. In addition, some problems in the past (repair content, repair period, maintenance costs) have been rectified, so that the division of labor between use and maintenance has gradually become clear.

For the current maintenance of the testing machine, it is generally the same as the Measurement Instrument, to carry out regular inspection, to clarify the normal or not of the testing machine, and to prevent the occurrence of failure, these are the purpose of reasonable maintenance.

The inspection is divided into: structural inspection to observe and measure the wear, deterioration and installation accuracy of components; This is a function check to confirm the temperature, vibration, sound, and eccentricity of the rotation and sliding mechanism, and an accuracy check to confirm the indication accuracy. In addition, (1) precision inspection, (2) simple inspection, and (3) local inspection are all performed at a time determined by each of the methods of inspection. Local inspection can be carried out at any time to detect and observe its external and moving conditions. As for the local inspection before the start of the daily work and at the end of the work, it is carried out by the operator. Pre-work inspections and cleaning are also beneficial for the service life of the testing machine. Therefore, the operator should be made aware of the importance of local inspections and be able to do so. As a measure, it is to make effective use of checklists. However, despite the emphasis on local inspections and maintenance work before and after work, it does not solve the problem of preventing the machine from deteriorating and extending its life indefinitely, and the possibility of a certain degree of failure. Of course, there is some value in reducing the speed at which the machine deteriorates.

It is necessary to establish a system that allows the maintenance period to be discovered in a timely manner through the above-mentioned inspections, and to carry out economical and timely rehabilitative repairs. Therefore, it is necessary to record the results of regular inspections and keep abreast of the deterioration of the machine. Finally, in order to avoid failures due to errors in judgment of maintenance personnel, or to reduce accuracy and cause product quality problems, it is necessary to train maintenance personnel frequently and continuously improve their maintenance skills.

2. Inspection

As a testing machine composed of mechanical parts, it is unavoidable that the wear and tear of the parts and the loosening of the tightly fitting parts are unavoidable. As a result, these phenomena will have a great impact on the accuracy of the testing machine. In addition, the impact of the destruction test on the specimen will act on the various parts of the testing machine repeatedly, so the testing machine will inevitably be damaged. A Tensile Testing Machine is a machine that is used under an impact that is called "measuring the impulse of a metal hammer striking a measuring instrument".

Therefore, it is needless to say that the newly installed testing machine, even if it is already in use, it is necessary to conduct regular inspection to see if there are any abnormalities in its structure, function and indication accuracy. In addition, the inspection results of the testing machine should be recorded to accurately grasp the history of the testing machine and achieve the purpose of timely detection of the maintenance period. At the same time, regular inspections are required in order to carry out cost-effective repairs in a planned manner.

An important issue here is the question of the maintenance standards of the testing machine. and what are the criteria that need to be clearly defined in determining the relationship between component aging and wear and replacement period (i.e., service time and maintenance discontinuation due to the number of tests). If this standard cannot be clarified, there will be errors due to the level and personal judgment of the maintenance personnel, and such maintenance will not be satisfactory. So, the development of standards is. Very necessary.

The testing machine needs to have good performance. The instructions need to be sensitive and accurate. However, due to frictional resistance from each component, deformation of the parts, and incorrect combinations, these structural defects may affect the accuracy.

The testing machine needs to have good performance. The instructions need to be sensitive and accurate. However, due to frictional resistance from each component, deformation of the parts, and incorrect combinations, these structural defects may affect the accuracy.

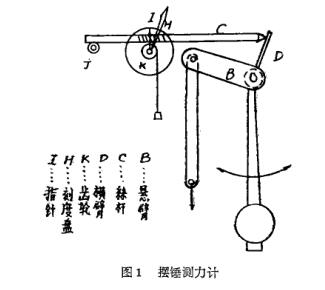

Most of the Tensile Testing Machines here use pendulum dynamometers. This kind of device is very sensitive, so the structure is also complicated, and there will be problems that affect the accuracy. Especially in the case of unskilled technology, it is not sure that the pendulum dynamometer can be disassembled and repaired, and it is necessary to carry out this work by skilled personnel. It is generally believed that errors are caused by this pendulum dynamometer, so it is only natural that this device should be particularly noteworthy. Figure 1 shows the structure of this device. If the instrument error at the time of each test is accumulated, it becomes a considerable error (error accumulation). This phenomenon is related to the meshing force between the screw rod, the gear and the guide wheel, and when the screw touches the cross arm, in addition to the linear motion, it also makes a rotary motion, and at this time, the instrument error will also be generated. This kind of instrument error, because the tooth pitch is very small, the screw only rotates a little, so it has no great impact on the load accuracy; However, when the screw rod is retrograde, the screw rod does not reverse or rotate, but only moves in a straight line, and the result is a zero change. At this time, the operator needs to pay attention to the problem that it needs to be adjusted to the zero position again with the zero adjustment device. If not, if the test is repeated, the instrument error will gradually accumulate, resulting in unexpected instrument error. However, if the operator can pay attention, this instrument error can be avoided. As a maintenance work, it is necessary to adjust the installation position of the screw, gear and guide wheel, so that even if continuous work is carried out, the cumulative error of this instrument will not be generated. At the same time, the screw rod is bent, which will also produce the above-mentioned error, so it should be replaced.

In the previous inspection, the load check was carried out by adjusting the zero position each time, so the rotation of the screw rod was not regulated. However, in the future, this will be included as a performance test item for testing machines.

2~1. Accuracy management of testing machine

The inspection accuracy of the Tensile Testing Machine is expressed by the instrument error. The allowable error of the instrument is generally limited to 10%. However, the accuracy of the inspection has little to do with the accuracy of the inspection. In order to be able to determine the performance of the testing machine in a timely and systematic manner, it is necessary to carry out a tube easy inspection and a precise inspection. In the time between two periodic inspections, the accuracy that can be guaranteed is called the inspection accuracy; In addition, the allowable accuracy in use is called management accuracy.

(1) Inspection accuracy: 0·5% is set with reference to various data and data so far. The testing machine with an inspection accuracy of less than 0·5% can be guaranteed for one year according to the normal use frequency.

(2) Management accuracy: 1·0%, which is the allowable limit. After maintenance, the minimum management accuracy of the testing machine is required to be carried out even if the simple inspection cycle is changedPerformance verification work (Usually the simple test is 6M, but there are also 3M times.) In addition, according to the results of the tube easy inspection, it is also possible to perform a temporary precision inspection.According to the results of the above inspection, it is also possible to carry out repairs earlier than planned.

3. Repairs

As mentioned above, based on the results of the inspection, we can accurately grasp the deterioration of the testing machine and decide on the items to be repaired. However, at this stage, the maintenance standard has not yet involved the more subtle parts, so most of them are just to see, and the maintenance standards for the more subtle parts are the topics that need to be discussed. The Tensile Testing Machine here is regularly inspected and overhauled by the former "External Grading Association".

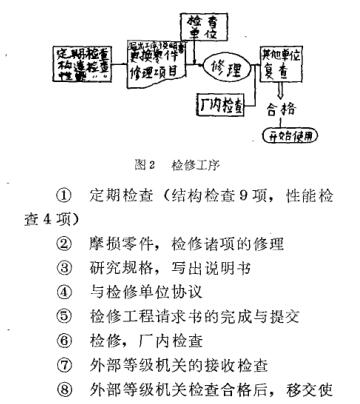

In the beginning, we relied on manufacturing units for our overhaul work. As mentioned above, some of the old testing machines were also carried out by the manufacturing unit, but due to the problems of preparing parts for the NORORO machine, the cost was too large, and the time was too long, in order to solve these problems, it was necessary to study the specifications according to the maintenance plan and reach an agreement with the manufacturing unit. The overhaul process is shown in Figure 2.

3~1. Pump overhaul

It is difficult to grasp the reduction of pump performance only by relying on local inspection in the test work. As a simple test to detect abnormal phenomena, a sex Tester is used to observe whether there is a slight vibration work. According to the amplitude of the Tester pointer, the maintenance or dismantling plan is formulated. However, even with ordinary tests, it is possible to detect the vibration of the pointer. In this case, it should be noted that the attenuation of the pump's performance can be solved by the vibration of the pointer. In general, it is solved by adjusting the placement state of the specimen (adjusting the bearing surface on the back of the chuck and making it contact appropriately).

For a long time, the maintenance of the pump used in the Tensile Testing Machine was to replace the parts that were considered to be unqualified, and the others were inspected and corrected by visual inspection. However, in the past, after the pump was overhauled, there was an accident in which the suction ring was rotated. The reason for this was found to be due to the presence of old cracks in the rotary pump. Therefore, in the future maintenance project, it was decided to use non-destructive inspection methods (such as magnetic testing, immersion testing, etc.) to inspect the rotating shaft. However, inspections require a very skilled and specialized program for non-destructive inspections. In the usual use of local inspection, the use of "listening stick", is more effective, therefore, this inspection method, is also worth studying.

4. Some questions about safety devices

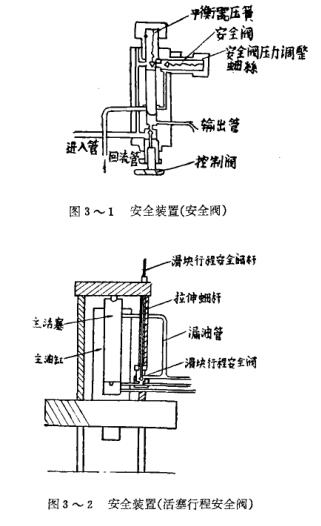

The safety device of the Tensile Testing Machine, as we all know, is installed with (A) a limit switch for controlling the upper and lower limits of the workbench, and (B) a maximum limit pressure safety valve(Figure 3 is a summary of the safety device of the testing machine) according to this, to 1 big to the safety of the main engine.

Most Tensile Testing Machines use range switching, and there is no safety device for the power part in the low range range. In other words, when working in a low range, the range of motion of the power part is the same as that of the maximum range. Since there is ample leeway for loading, it is not necessary to pre-envisage the damage to the installationPrepared questions. In addition, the operating point of the safety valve also varies according to the temperature of the oil, so it is not easy to adjust the safety. Although it is stipulated that the load safety device should be carried out within 1.5 times the maximum capacity, there is no regulation on how long it takes for the oil temperature to stabilize from the start of work to the time it takes. According to the investigation, the temperature of the oil did not stabilize 60 minutes after the testing machine started working. For testing machines that have been used a lot of times, there is no big problem. For the testing machine that is used a few times, there is indeed an action point, and the setting is the same problem. In order to solve the above problems, through research with maintainers, the results are:

(1) When the moving part reaches the movable range pole. For a limited time, the power part (pump drive motor) is immediately stopped, and at the same time, a program device is installed to sound an alarm.

(2) For the movable range device, it is necessary to place the part where the same movement can be obtained at all levels.

(3) The position of the limit switch should be installed so that its action cannot have a bad influence on the action of the pointer.

(4) The limit switch needs to be installed in a place where local inspection is easy to perform.

At present, the design of the safety device of the testing machine for the purpose of meeting the above four requirements has entered the implementation stage. The safety device of the testing machine should be coordinated with the repair period of each testing machine, and can be taken into account first. The feature of this safety alarm is that even when the operator leaves for stable operation at all levels, the abnormal phenomenon of the machine can still be known and grasped by relying on the alarm.

Some problems with the useWhen the testing machine is running, it should be noted that the room temperature should be maintained at a certain level, and when the machine is shoulder-moving, the control valve and release valve should be fully opened, and the idle should be carried out for several minutes to fully circulate the pressure oil. This is done in order not to damage the oil pump and its piping.

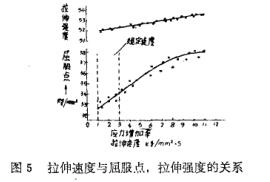

During the test, the tensile speed specified in the JIS-B-7771 tensile test method for metallic materials was unstable even though the tensile speed was controlled. The reason for this is that it is very difficult to control the tensile speed after the testing machine is in operation. The main reasons are: (1) workload, (2) the degree of valve opening, and (3) temperature. The relationship between each quantity and velocity is shown in Figures 4 and 5 respectively. The working time is clarified on the oil temperatureThe relationship with the tensile speed is that when the oil temperature is stable at 30~32 °C, the tensile speed is also stable. In addition, for the change of tensile speed, the yield point and tensile strength change is, when the tensile speed is 3~91, g/mm2S, the yield point is 4kg/mm2, and the tensile strength is 1kg/mm2. Among them, there is a great influence on the yield point, which is due to the pendulum type relationship of the testing machine.

As mentioned above, the tensile speed has a great influence on the test value, so it is necessary to control the tensile speed very accurately. For this reason, if the temperature can be controlled to a certain level (30~35°C), it is easy to adjust the speed, and this problem can be solved.

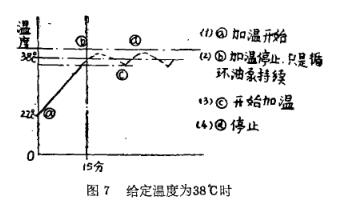

As a measure to control the temperature, an oil heating device is installed. After the installation of this unit:

(1) After the start of the work (it takes about 15 minutes for the heating device to heat up), the tensile speed is stable before the test can be carried out.

(2) The testing machine with fewer times of use and high load can also achieve more stable operation than before. -

(3) The work of the safety hill can also be stable.

5~1. Performance of the heater

(1) The name and nature of the oil: No. 40 engine oil.

(2) Heating speed: 60 liters of No. 40 engine oil, with 15 minutes, can be heated to 22~38 °C.

(3) Temperature control: The control is only automatically carried out when the heater is heated.

(4) Heating action

(5) Heater capacity: 3KW

epilogue

The testing machine mentioned above is described by taking the Amsra hydraulic multi-functional testing machine as an example. The obvious problem is how to implement standardization (maintenance standards, inspection standards). As for the acceleration of automation in the future, the fundamental idea is the same. We need to work hard to improve our skills and knowledge through our daily work.