1. Definition and core function of fog shadow meter

Fog shadow meters are professional optical inspection instruments based on diffuse reflection principles, used to quantify key parameters such as haze, transmittance, and clarity of transparent or translucent materials. It evaluates the optical uniformity and visual quality of materials by simulating the scattering behavior of light on the surface and inside the material.

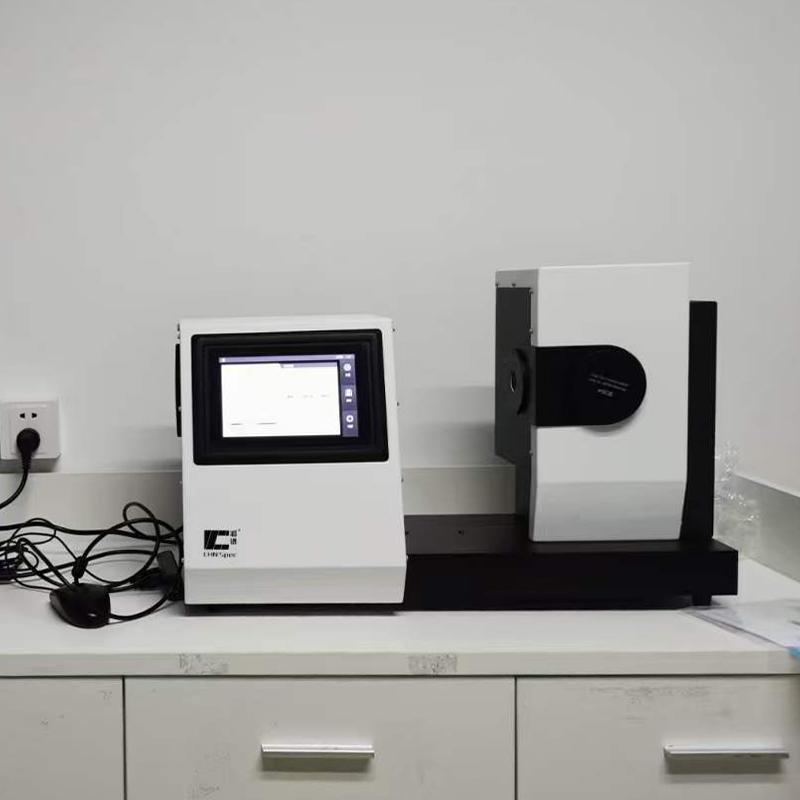

The traditional fog shadow instrument adopts a dual-beam system, and the modern equipment is upgraded to a long-lasting LED light source (with a lifespan of up to 10 years), equipped with automatic calibration function and intelligent operation interface (touch screen, data storage 5000+ records, multi-mode data transmission), which improves measurement stability and operation convenience.

2. Core measurement parameters and application fields

(1) Key measurement parameters

1. Haze: Reflects the ratio of light scattered by the material, affecting the clarity of transparent materials. Optical grade plastics require a haze of <1%, and packaging films allow 5%-10%.

2. Transmittance: Measuring the transmittance of light, high transmittance is suitable for fields with high optical efficiency requirements, such as photovoltaic glass and display panels.

3. Clarity: Determining the ability to resolve imaging details, electronic screen protectors need to take into account both high transmittance and clarity.

4. Vividness (DOI): Evaluates the sharpness of reflected images on high-gloss surfaces (e.g., car paint, metallic coatings), with higher values being clearer than those of other materials.

(2) Typical application industries

1. Automobile manufacturing: Detect the vividness of car paint, window glass transmittance and optical uniformity of interior parts to ensure appearance quality and driving safety.

2. Electronic display: quantify the optical performance of LCD panels and protective films to avoid blurring screen display or color distortion.

3. Packaging and printing: Optimize the transparency and haze balance of food packaging films and labels, taking into account content visibility and barrier performance.

4. Building materials optics: Detect the lighting efficiency and imaging quality of optical lenses of architectural glass, and are used in high-end buildings and precision instruments.

3. Selection strategy and technology trend

(1) Key factors in selection

1. Measurement requirements: basic requirements (haze/transmittance) or advanced parameters (vividness/image quality).

2. Material characteristics: select the measurement angle according to the gloss (high gloss 20°, general 60°, matte 85°), and some equipment supports multi-angle linkage measurement.

3. Functional scalability: Priority support for multi-parameter synchronous detection, large-capacity data storage, and compliance with international standards (such as ASTM D1003, ISO 13468).

4. Ease of operation: Adaptable to different sample sizes of measurement apertures (7mm-21mm), automatic calibration function, and stable LED light source system.

5. Comprehensive cost: The basic model is suitable for routine quality inspection of small and medium-sized enterprises, and the high-end model meets the needs of R&D centers for precision and functional expansion.

(2) Technological development trends

Modern fog shadow instruments are developing in the direction of high precision, multi-functional integration and intelligence. Some devices integrate spectral analysis functions to provide more comprehensive optical performance evaluation; The improvement of data processing capabilities supports real-time quality monitoring and helps Industry 4.0 intelligent manufacturing. Advances in LED light source and Detector technology have significantly improved measurement sensitivity, and software algorithm optimization has made data interpretation more intuitive.

4. Maintenance and comprehensive suggestions

To ensure measurement accuracy, regular maintenance and calibration are required according to manufacturer recommendations. Keep the optical components clean during daily use to avoid dust affecting accuracy. For high-precision applications, it is recommended to establish a well-established calibration and verification procedure.

Summary: Fog shadow meters provide critical data support for product quality control in automotive, electronics, packaging, and other industries by accurately measuring optical parameters. When selecting a model, it is necessary to comprehensively consider the measurement needs, material characteristics and cost-effectiveness, and choose the appropriate instrument to improve the testing efficiency and product quality.