1. Classification of types of halogen Moisture Meters

As technology continues to evolve, halogen Moisture Meters have evolved into a variety of different models to meet the specific needs of different industries.

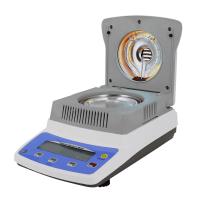

Basic equipment focuses on economy and ease of use. It uses a standard ring halogen lamp for heating, and with a basic weighing module, it can complete the moisture detection of conventional samples such as grain and chemical raw materials in a relatively short time. This type of equipment is relatively simple to operate and is ideal for small and medium-sized businesses for daily quality control work.

The high-precision model is mainly aimed at application scenarios with strict testing requirements. With the help of advanced sensors and fine temperature control technology, it can improve the resolution of moisture to a high level, and can generate detailed water evaporation curves, providing strong data support for related research work.

The multifunctional device has been further developed with integrated functions such as data storage, automatic calibration and a multilingual operator interface. This not only meets the needs of laboratories to process samples in batches, but also meets the relevant specifications. The portable model, with its lightweight design and low-power mode, provides great convenience for on-site inspection services, such as agricultural field sampling or engineering field material acceptance.

From the perspective of heating principle, halogen lamp heating is through the synergy of tungsten wire and halogen gas, which effectively extends the service life of the equipment. Quartz halogen lamps rely on high light transmittance materials to enhance the penetration of heat radiation, making them especially suitable for uniform heating of thin sheet or layered samples.

2. Cross-industry application practice of halogen Moisture Meter

The food industry is one of the most widely used halogen Moisture Meters. In the grain storage process, the equipment can quickly detect the moisture content of wheat, rice and other grain crops, and detect the risk of excessive moisture in time, so as to effectively prevent the occurrence of mildew and other losses. Bakery companies use halogen Moisture Meters to monitor the moisture content of dough in real time, thereby optimizing fermentation and baking parameters to ensure consistent product taste.

The chemical industry uses halogen Moisture Meters to optimize the pretreatment process of raw materials such as plastic particles and rubber to prevent defects in injection molding and other processes due to excessive moisture. Textile enterprises use this equipment to detect the moisture content of fibers, so as to adjust the spinning tension and improve the strength of the finished product.

In environmental monitoring scenarios, halogen Moisture Meters can be used to analyze sludge dewatering effects or soil moisture, providing an important basis for sewage treatment plants and agricultural departments to make relevant decisions. In addition, halogen Moisture Meters also play an indispensable role in industries such as coal, papermaking, and electronic materials.

3. The five core elements of scientific selection

(1) Accurately define the detection objectives

First of all, it is necessary to clarify the specific form of the sample, whether it is granular, powdery, liquid, or other special forms; determine the approximate range of moisture content, whether it is trace moisture or high moisture content; At the same time, the required level of accuracy is clarified, as conventional testing differs significantly from some inspection scenarios that require high accuracy. For example, when detecting chemical raw materials containing volatile components, it is necessary to choose a model that supports low-temperature drying mode to avoid the loss of active ingredients.

(2) Evaluate key technical indicators

The performance of the heating system has a direct impact on test efficiency and heating uniformity. Halogen lamps with a power of 450W - 500W can achieve high-precision temperature control at 180°C, and the design of pure stainless steel heating chambers can effectively reduce the risk of local overheating. The sensitivity of the weighing system (minimum reading up to 0.001g) and the range (generally 50g - 200g) determine the sample size that the device can apply, and the high-precision sensor can resist the interference of environmental vibrations to ensure the stability of the measurement results.

(3) Pay attention to intelligence and automation functions

Devices with automatic shutdown (based on constant weight determination), multiple mode preset functions (e.g. fast drying mode, gentle drying mode, etc.), and dynamic endpoint recognition technology (e.g., automatic termination of the test when the weighing change is less than 1mg three times in a row) can significantly reduce errors caused by human operation. At the same time, the data storage function and communication interface of the equipment (such as RS232, USB interface, etc.) are convenient for connecting the test data to the laboratory information management system to meet the requirements of relevant specifications.

(4) Environmental adaptability and long-term cost

The equipment needs to be able to adapt to different working environments, whether it is a laboratory environment (temperature range 5°C - 50°C, humidity not exceeding 80% RH) or an industrial site environment (which requires a certain dust and water resistance rating, such as IP54). The durability of the equipment (e.g. with wind shields, stainless steel housings, etc.) and low maintenance costs (long service life of halogen lamps and reasonable calibration intervals) are important guarantees for long-term economics.

(5) User experience and expansion potential

Intuitive user interfaces (such as touch screen operation or knob and digital tube combination) and multilingual support reduce learning costs and make the device easier to use. The modular design allows users to upgrade the hardware capabilities of the device at a later stage, thereby protecting the value of the user's investment.

conclusion

The selection of halogen Moisture Meters is not a simple comparison of parameter lists, but requires comprehensive consideration of multiple factors such as sample characteristics, detection accuracy requirements, working environment conditions, and long-term use costs. Whether it is the economic practicability of basic equipment or the precision analysis capabilities of high-end models, a reasonable choice will directly improve the efficiency of testing work and the reliability of data, and provide solid technical support for the high-quality development of various industries.