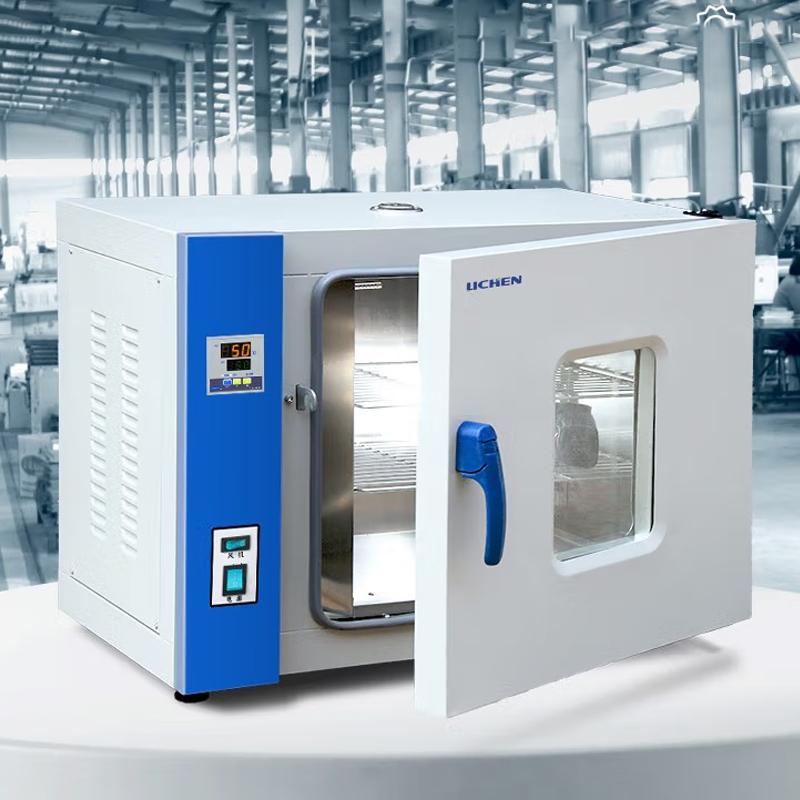

Electric heating drying oven is a kind of equipment that dries, heat treats and heats items by electric heating, according to its structure and functional characteristics, it is mainly divided into three types: ordinary electric heating drying oven, electric heating blast drying oven and electric heating closed drying oven.

Main types and characteristics

Ordinary electric heating drying oven

It adopts natural convection heat exchange method, and the structure is relatively simple, mainly composed of a box, heating element and temperature controller. The studio is filled with fiberglass insulation between the enclosure and the door is equipped with a viewing window for easy viewing of the interior. This type is suitable for occasions where temperature uniformity is not required.

Electric blast drying oven

On the basis of the ordinary drying oven, a blower device is added to make the temperature in the box more uniform by forced hot air circulation. It is usually equipped with two sets of heating elements, which can be selected according to needs, and has an over-temperature alarm system for greater safety.

Electric heat closed drying oven

Specially designed for processes with special requirements, such as paint coating finishes. It adopts a double-layer cabinet structure, equipped with electric heating pipes without open flames, and is equipped with a safety door that can automatically open when the pressure in the box exceeds the set value to prevent explosions.

Usage points

Before using the electric heating drying oven, first check the electrical performance to ensure that there are no circuit breaks and leakage. When placing the sample, care should be taken to leave appropriate gaps to ensure that the hot air can circulate normally. It is not advisable to place items on the floor of the studio so as not to affect thermal convection.

After powering on, first adjust the temperature control knob to the desired temperature position, and then adjust it in reverse until the indicator light goes out after the temperature rises to the set value. At this time, due to thermal inertia, the temperature may continue to rise, and it will take about half an hour to stabilize. In the constant temperature state, a set of heating elements can be turned off, saving energy and reducing temperature fluctuations.

For the electric blast drying oven, confirm that the blower is steered correctly before use; For the electric heat closed drying oven, when baking items containing volatile substances, the exhaust valve needs to be opened in advance to discharge the solvent vapor in time.

Maintenance

During daily maintenance, special attention should be paid to the cleaning and maintenance inside and outside the box, and the shelves and workshop walls should be cleaned regularly. The electroplating parts and paint layer should be properly protected to prevent corrosion. The motor and blower should be cleaned and refueled regularly, and abnormal noise should be repaired in time.

Special attention should be paid to safety: non-explosion-proof drying ovens must not be used for baking flammable and explosive items; Do not open the box door suddenly in high temperature to prevent the glass viewing window from breaking due to rapid cold; When the temperature rise of the electrical control components is abnormal, it should be stopped immediately for inspection.

summary

As a commonly used heat treatment equipment, the correct selection and use of electric heating drying ovens are crucial to ensure process quality. The normal type is suitable for basic drying needs, the blast type has a more uniform temperature, and the closed type has higher safety. No matter which type is used, it is necessary to follow the operating procedures, do daily maintenance, and pay special attention to safety matters to ensure the long-term stable operation of the equipment and give full play to excellent performance.