In packaging printing, label products and various printed materials quality control, the durability of printing ink is a crucial performance indicator. Ink decolorization test, often referred to professionally as ink abrasion resistance test, is a key means to evaluate the ability of printed products to resist friction and color loss during circulation and use. This test provides an objective and quantitative data basis for the printing adaptability of packaging materials, the optimization of ink formulations, and the determination of the quality grade of the final product by simulating friction in real scenarios.

The quality of the abrasion resistance of the ink layer directly affects the durability of the product's appearance, the maintenance of the brand image and the readability of information, and is the core index for evaluating the quality stability of printed products. For example, when food packaging is in transportation and stacking, and when product labels are rubbed in handheld hands on a daily basis, printed patterns are required to have sufficient friction resistance. Therefore, systematic ink decolorization testing is widely used in ink research and development, printing process optimization, finished product quality control, and compliance certification.

1. Test principle

The core principle of ink decolorization testing is to simulate the actual friction conditions and evaluate the performance of the ink layer by quantifying its resistance to shedding. Standard test methods typically use a motor-driven reciprocating friction mechanism in which a friction head with a standard pressure covered with a specific friction medium (e.g., white Dowling paper, standard cotton) is repeatedly rubbed against the surface of the printed specimen at a specified stroke and speed. The wear resistance of ink is scientifically evaluated by comparing the color change of the ink before and after friction, the shedding area or the degree of color staining of the friction medium.

Different regions and industries around the world have formed a series of mature technical standards for ink decolorization testing, providing unified parameter specifications and performance thresholds for testing.

2. Main test standards

QB/T 5345-2018"Test Method for Friction Fastness of Ink

——The current direct ink friction fastness industry inspection method standard.

GB/T 46445.1-2025Imaging Materials and Printed Materials Abrasion Resistance Part 1: General Friction Test Methods

- New national basic common test method standards to be implemented in 2026.

ISO 105-X12《Textile Color Fastness Test, Part X12: Color Fastness to Friction》

——The internationally used friction color fastness test method is often extended to the evaluation of printed products.

ASTM D5264Standard Test Method for Determining the Abrasion Resistance of Printed Materials Using the Sutherland Friction Tester

- American Materials Institute standard, widely used in international trade.

GB/T 7706-2008"Letterpress Decoration Print"

——Toppan printed comprehensive product standards, non-special test methods, need to pay attention to distinction.

GB/T 18724-2024《Printing Technology, Printed Matter and Printing Ink: Determination of Resistance to Various Reagents》

——General standards for evaluating the resistance of reagents such as water resistance, solvents, acids and alkalis in printed materials.

GB/T 13217.7-2009"Liquid ink adhesion fastness test method"

——Basic method standard for testing ink adhesion fastness.

3. Test method

According to the state of the friction medium during the test, it is mainly divided into the following methods:

Dry friction testing – simulating friction in dry condition – is the most basic test method used to assess the abrasion resistance of most common packaging and printed materials.

Wet friction test - adding distilled water or a specific solution to the friction cloth to simulate friction in a humid environment (such as condensation, sweat) can test the water resistance and adhesion fastness of the ink more severely, which is especially important for beverage packaging and refrigerated food labeling.

Decolorization change and fuzz testing - focusing on evaluating the color migration of ink under the action of solvents or the rubbing phenomenon of undried ink stains, which is of special significance for the quality control of UV inks, water-based inks and other specialty inks.

4. Test instruments

The key equipment to achieve the above standardized tests is the ink abrasion resistance tester (also known as friction testing machine and decolorization testing machine). A standard-compliant instrument typically consists of the following core systems:

(1) Power and transmission system

High-precision stepper motors or similar drives are used to ensure that the friction head moves in a straight or arc at a constant speed (such as 21, 43, 85, 106 times/minute) and a fixed stroke (commonly 60mm) to ensure the uniformity and repeatability of the test conditions.

(2) Loading system

Provides precise control of vertical pressure. By configuring standard weights or load blocks of different weights, multiple pressure settings (such as 8.9N, 17.8N, 20N, etc.) can be realized to simulate friction of different intensities.

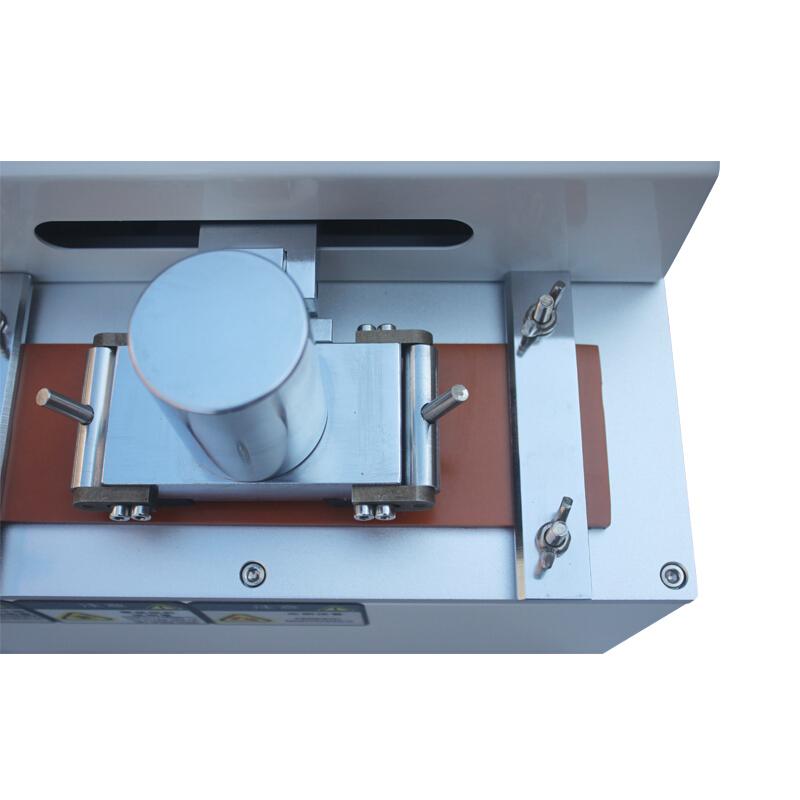

(3) Friction head and clamping system

The friction head has a defined effective contact area that covers a standard white friction cloth or specific spacer. The specimen clamping platform is used to hold the printed material to be tested flat and securely, ensuring that no displacement occurs during the test, which is an important prerequisite for ensuring the accuracy of the results.

(4) Intelligent control system

Modern high-end models are usually equipped with microcomputer or touch screen control systems, which support free setting and real-time display of parameters such as pressure, speed, and friction times (0-9999 times), and have functions such as automatic counting, automatic shutdown when reaching the set value, data storage and export, which greatly improves the automation level and data traceability of the test.

5. Specific applications

Ink decolorization testing instruments run through the whole chain of product research and development, production to certification, and are indispensable tools to ensure quality.

(1) R&D stage - formula optimization and performance verification

In ink development, testers are used to verify the effects of different resin systems, pigments, and additives on the adhesion and wear resistance of ink layers. For example, when a company developed water-based inks for food flexible packaging, it was found that the initial formula of abrasion resistance was not up to standard, and finally increased the dry friction wear resistance of the product from 300 times to more than 500 times by adjusting the proportion of polyurethane resin and adding adhesion promoters, which met the industry requirements.

(2) Production stage - process monitoring and quality screening

In mass print production, regular sampling testing is an effective means of monitoring quality stability. For example, a flexible packaging factory found that the wear resistance of a batch of products plummeted from the required 400 times to 280 times due to insufficient ink curing agent through each batch test, so as to quickly correct and avoid large-scale losses. Testing also helps optimize process parameters such as printing pressure, drying temperature, etc.

(3) Quality control and certification stage - compliance pass

Unified testing standards and methods are a common language for upstream and downstream communication in the supply chain. Many international brands and industry norms (such as food contact materials GB 4806.10, EU REACH regulation) have clear requirements for the wear resistance of printed materials. Reliable test reports from compliant testing instruments are necessary for companies to enter specific markets, especially in the areas of food, children's products, and luxury packaging.

4. Operation process

The standard test process usually includes: conditioning the specimen under a standard temperature and humidity environment (such as 23±2°C, 50±5% RH); The standard friction medium is fixed flat on the friction head; The specimen is firmly clamped on the platform; Set parameters such as pressure, speed, and frequency; Startup test; The results are evaluated after the test.

There are two main ways to evaluate results:

(1) Subjective visual comparison

Use gray sample card or dyeing ratio card to compare the degree of color staining of the friction cloth or the area of ink shedding of the specimen to evaluate the color staining grade or wear level.

(2) Objective instrument measurement

Use a colorimeter to measure the color difference value (ΔE) between the tested and untested areas, or use a density meter to measure the density change for quantitative evaluation for more accurate and reproducible results.

Common Problems and Solutions:

Question:The reproducibility of the test results is poor, and the data of the same batch of samples fluctuates greatly.

Causes and solutions:Often stems from inconsistencies in the operation or sample. It is necessary to ensure that the thickness of the printing ink layer is uniform; The specimen is completely flattened and clamped; The friction medium is installed flat and without wrinkles; The temperature and humidity of the laboratory are constant.

Question:How to choose the right test method for your product (dry, wet or solvent rub)?

Recommendations:First, follow the country, industry or customer standards corresponding to the product. If there is no clear provision, risk analysis is conducted based on the actual usage scenarios of the product. For example, outdoor products need to consider rain resistance, and wet wipe is optional; Edible oil packaging needs to be evaluated for grease resistance.

Question:How to test for curved prints such as caps and hoses?

Solution:Standard planar friction gauges may not be suitable. There are usually two methods: one is to make a simulation test piece (copy the surface printed area to a flat substrate); The second is to contact instrument suppliers to customize special-shaped fixtures and friction adaptation devices.

5. Conclusion

With the development of the industry, ink decolorization testing instruments are evolving in the direction of higher accuracy, greater intelligence and wider adaptability. Integrating high-precision sensors to achieve real-time ΔE monitoring, data cloud management and analysis through IoT technology, and developing fixtures that adapt to more special-shaped substrates will become the focus of future equipment upgrades.

All in all, ink decolorization testing instruments are a precision bridge connecting ink research and development, printing process and terminal quality requirements. An in-depth understanding of its testing principles, core standards and the characteristics of different types of instruments can help printing and packaging enterprises, ink manufacturers and quality inspection institutions scientifically select equipment and establish a rigorous quality control system, and ultimately ensure that products maintain long-lasting visual quality and safety performance in fierce market competition and complex use environments.