I. Overview

DHT-300 Leeb Hardness Tester uses the Leeb principle to test the hardness of various metal materials. The instrument is small in size and is especially suitable for testing in various working environments. According to the national standard GB/T 17394-1998, the Leeb hardness can be easily converted into the common hardness scales of HRC, HRB, HV, and HS.

Before using the instrument, please read the manual in detail to understand the performance of the instrument and master the use of the instrument.

This instrument conforms to the national standard GB/T 17394-1998 of the People's Republic of CHINA;

This instrument has passed the production license of the State Bureau of Quality Supervision, and the license is: CMC Beijing 101080114;

This instrument has passed the E CE and C EMC certification of German Rheinland Technology (TUV) company.

2. Technical parameters

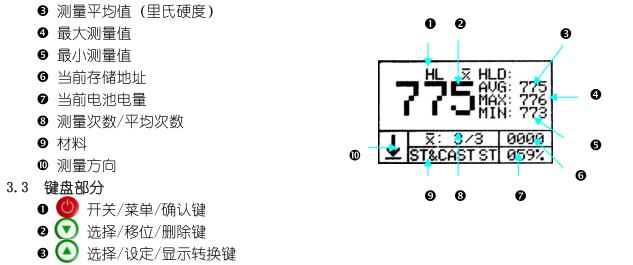

Display method: 112×64 LCD dot matrix liquid crystal display

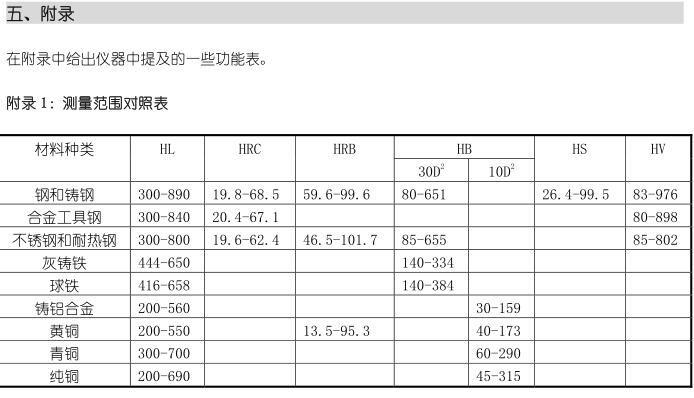

Measuring range: HL 200 - 960

HRC19.6 - 68.5

HRB 13.5 - 101.7

HS 26.4 - 99.6

HB 30-655

HV 80 – 976

Special Note: Please refer to Appendix 1 (page 19) for the measurement range of different measurement materials.

Indication accuracy: relative error ±0.5% (HL=800)

Repeatability ±0.8%

Storage memory: Automatically store 1250 sets of measurement data.

Batch storage There are 12 batches, and each batch stores 100 sets of data.

Power supply: 3.7V rechargeable lithium battery, can work continuously for not less than 16 hours

Automatic shutdown: automatic shutdown after 2 minutes of no operation

Operating environment: Operating temperature: -20°C - +40°C

Storage temperature: -30°C - +50°C

Dimensions: 158×41×26mm

Weight: 120g

4. Operation method

4.1. Preparation before use

4.1.1. Instrument preparation

4.1. Preparation before use

4.1.1. Instrument preparation

For newly purchased instruments, please refer to the packing list (see page 21) to check the contents of the instrument and accessories.

Do not use the instrument if it is damaged, and contact the manufacturer as soon as possible.

4.1.2. Requirements for the test piece

1) The surface temperature of the test piece cannot be overheated <80°C;

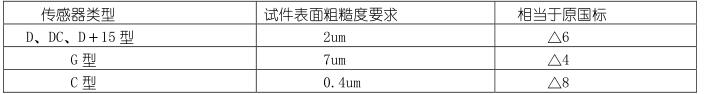

2) The requirements for the surface roughness of the test piece are as follows:

4.1.3. Requirements of the Hardness Tester for the weight of the tested piece

1) For specimens weighing more than 5kg, no support is required;

2) Specimens weighing 2-5kg with overhanging parts and thin-walled specimens should be supported by objects during the test to avoid deformation, bending and movement of the specimen caused by the impact force;

3) If the weight is less than 2kg, it should be tightly coupled with the support body weighing more than 5kg. It is required that the surface of the test piece and the coupling body must be flat and smooth. perpendicular to the coupling plane.

4.1.4. Requirements for surface hardening layer of test pieces

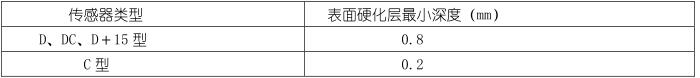

When measuring the hardness of the surface hardened layer of the test piece, the impact force such as penetrating the hardened layer will make the measured value incorrect, so the depth of the surface hardened layer should meet:

4.1.5. The surface of the tested piece should not be magnetic.

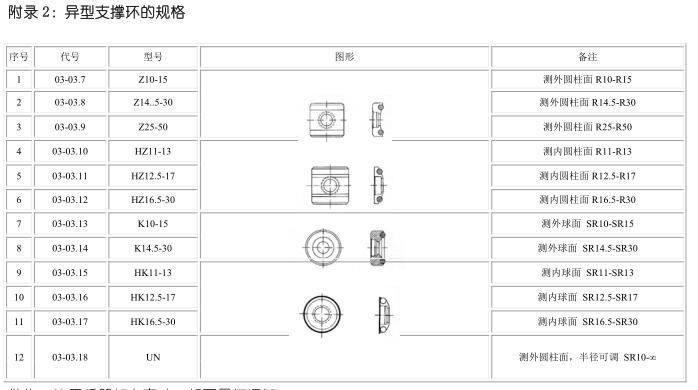

4.1.6. For the test of the specimen whose curved surface radius is less than 30mm, a small support ring should be used, or a special-shaped support ring should be selected (see Appendix 2, page 23).

4.1.6. For the test of the specimen whose curved surface radius is less than 30mm, a small support ring should be used, or a special-shaped support ring should be selected (see Appendix 2, page 23).

4.2. Sensor operation

4.2.1. Loading

Push the load sleeve down all the way, grab the impact body, and return the load sleeve.

Note: Do not spring back the loading sleeve freely to avoid damage to the sensor.

4.2.2. Positioning

Press the sensor vertically on the workpiece surface in the selected measuring direction.

4.2.3. Release

Press the release button to release the impact body for measurement.

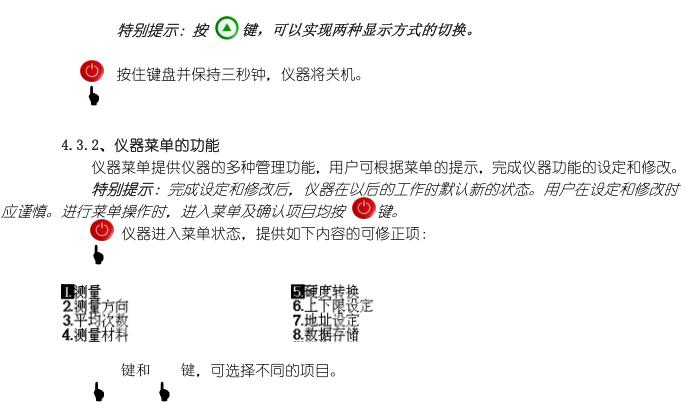

4.3. Instrument operation

The operation of the instrument is a full Chinese menu, and the operation is extremely simple. The following describes the operation of the instrument in detail.