With the development of the market economy, the application of Tensile Testing Machines is becoming more and more extensive. There are many Tensile Testing Machines used to test the tensile properties of materials. Different brands and models have different performances. How can I choose one suitable for What about Tensile Testing Machines for packaging materials? According to the national material testing standards, this paper analyzes the most critical indicators of the Tensile Testing Machine for packaging material testing.

The tensile properties of plastics and rubbers are one of the most important and basic properties in their mechanical properties, which largely determines the usage occasions of the plastics and rubbers. The quality of tensile performance can be detected by tensile test Song.

1. Tensile properties of polymers

When used as a material, high molecular polymers are required to have the necessary mechanical properties. It can be said that for most applications of polymers, mechanical properties are more important than other physical properties.

High-molecular polymers have the widest range of variability among all known materials in mechanical properties. This is due to the fact that high-molecular polymers are composed of long-chain molecules, and molecular motion has obvious relaxation characteristics. For example, high polymer materials have quite high elongation. Generally, the elongation at break of PE is 90% to 950% (of which linear low density polyethylene LLDPE has a higher elongation). Through special manufacturing processes, some materials The elongation at break can be above 1000%, while the elongation at break of ordinary polymer materials is mostly between 50% and 100%. Generally, heat shrinkable films and stretched films have higher requirements on the tensile properties of materials.

2. Tensile test

Tensile test (stress-strain test) generally clamps the two ends of the material sample on two fixtures with a certain distance apart, and the two fixtures separate and stretch the sample at a certain speed to measure the stress change on the sample. until the sample fails.

Tensile test is one of the widely used methods to study the mechanical strength of materials, which requires the use of a constant-speed Tensile Testing Machine. According to the different load measurement methods, the Tensile Testing Machine can be roughly divided into two types: the pendulum type Tensile Testing Machine and the electronic Tensile Testing Machine. At present, the electronic Tensile Testing Machine is used more.

3. Selection index of electronic Tensile Testing Machine

Since flexible packaging materials are mainly high molecular polymers or its related materials, as mentioned above, the elongation of high polymer materials is far superior to that of metal, fiber, wood, board and other materials, so the tensile machine testing for molecular polymers There is a certain difference from the usual material tensile performance testing tensile machine, especially the effective stroke of the electronic tensile machine and the sample fixture.

3.1 Effective stroke

In the tensile test, although the size of the sample used is small, the elongation of the material is generally relatively high. Therefore, it is necessary to equip a tensile machine with a relatively large stroke for testing the tensile properties of flexible packaging materials, otherwise the operation of the fixture may exceed The use limit of the stroke will cause damage to the equipment.

The formula for calculating elongation at break or elongation at yield (εt, unit is %) given in GB13022-91 "Test Method for Tensile Properties of Plastic Film" is as follows:

εt=(L-L0)/L0×100

In the formula: εt is elongation at break or elongation at yield; L is the distance between the marking lines when the sample breaks or yields; L0 is the distance between the marking lines.

It should be noted that in the calculation of elongation, we only collect the elongation between the two marking lines on the sample. Marking lines are printed by

or manually drawn on the prepared sample (the addition of the marking line should have no effect on the sample), and what is the distance between the marking lines? Most of the distances given by different standards have a certain However, in the same standard, different sample sizes are often given for different materials, so the distance between the marking lines is also different, but this is conducive to detecting materials with very large or very small elongation and obtaining accurate test results. For plastic films, the distance between marking lines is usually between 25 and 50mm.

Because the deformation and elongation of the sample in the tensile test is not only within the marked line, any sample between the two clamps will get different degrees of tensile deformation. In the standard, the initial distance between the grips corresponding to the marked line distance is within 80-115mm. If the sample between the two grips can maintain the same elongation rate and assume 500%, the effective stroke of the tensile machine must be 480 ~690mm, if it is a sample with an elongation rate of 1000%, the effective stroke of the tensile machine must be at least 880mm to ensure the normal progress of the test.

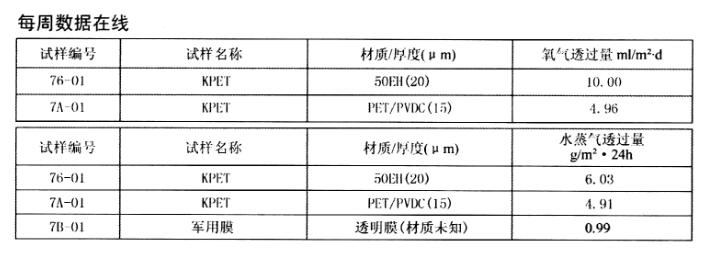

The author conducted a random survey on the effective stroke of the electronic tensile machines currently on the market, among the 72 tensile machines of several brands at home and abroad.

In the figure, Figure 1 represents equipment with a stroke of less than 500mm, accounting for 13.9%; Figure 2, equipment with a stroke of 500-900mm, accounting for 56.9%; Figure 3, equipment with a stroke of 901-1100mm, accounting for 20.8%; Figure 4 shows equipment with a stroke of more than 1100mm, accounting for only 8.4%. However, among the electronic tensile machines counted this time, not all the equipment with large strokes are used for the detection of flexible packaging materials, but some are used for tensile tests of artificial wood boards, canvas, curtains, copper materials and other materials.

3.2 Sample fixture

The description of the fixture in GB13022-91 "Test Method for Tensile Properties of Plastic Film" is: "The testing machine should be equipped with appropriate fixtures, which should not cause the sample to break at the fixture. When any load is applied, the fixture on the testing machine It shall be immediately aligned so that the long axis of the specimen coincides with the direction of tension passing through the centerline of the grips. ... Place the specimen in the two grips of the testing machine so that the longitudinal axis of the specimen is aligned with the upper and lower The center lines of the fixtures are coincident and should be tight enough to prevent the sample from slipping and breaking in the fixture. The fixture should be lined with elastic materials such as rubber.” Due to the special mechanical properties of polymer materials and the special use of soft packaging materials The method makes the sample thickness of the flexible packaging material test very thin, and the general fixture cannot meet the requirements. Improper use will cause the sample to break at the fixture and cause the test to fail.

3.3XLW(L)PC Intelligent Electronic Tensile Testing Machine

Labthink is an enterprise specializing in the production of testing equipment for flexible packaging materials. Especially for the characteristics of large elongation of flexible packaging materials, it has produced XLW(L)PC intelligent electronic Tensile Testing Machine. The stroke can reach 1000mm, and it can be stretched, peeled, and Seven kinds of tests, such as cracking and heat sealing, and professionally designed various test fixtures for flexible packaging materials. It is a mechanical performance Tensile Testing Machine tailored for flexible packaging materials.

The above is a summary of the author's experience in purchasing Tensile Testing Machines, hoping to provide some references for relevant personnel in the industry.