In order to measure the cold resistance of paint coatings under dynamic strain, Yakubovich, Vorogushin and Bam proposed a special device in which the cold resistance can be tested at different temperatures. It is measured by the impact test (the specific temperature varies with the requirements for the use of the coating film, and can reach -60°C, -70°C and lower temperatures).

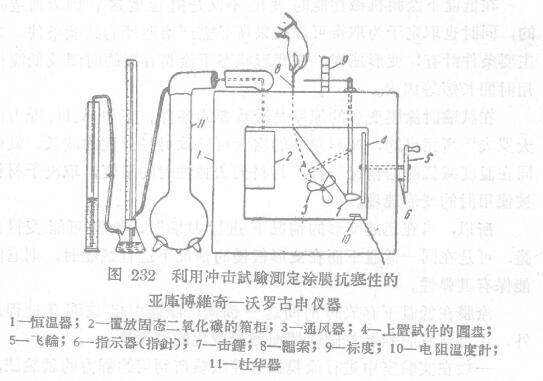

Such a device is a thermostat 1, in which solid carbon dioxide and liquid oxygen placed in a cabinet 2 are used for cooling. The amount of liquid oxygen delivered is regulated by the pressure in the Duhua vessel. The temperature is measured by the resistance thermometer connected in the circuit diagram of the bridge. In order to cause a uniform temperature, a ventilator 3 is installed indoors, and the motor on the ventilator is connected outside the side wall of the thermostat. In the interior of the chamber there is a vertical disc 4 on which a test piece is placed. (Related instruments: constant temperature and humidity Test Chamber)

The round handle of flywheel 5 can be utilized to turn this disc into a certain angle that can be read on the indicator 6 to show the degree. The movement of the disc causes the new surface of the test piece to be impacted with shock. A hammer 7 is arranged in the small chamber, and a standard steel ball with a diameter of 6 mm is embedded in the hammer, and this steel ball is the impact surface of the hammer. Use the rope 8 passing through the upper wall of the instrument to pull the hammer from the test plate to a specified distance. When the hammer falls, it will impact on the test piece fixed on the disc. The process is as follows.

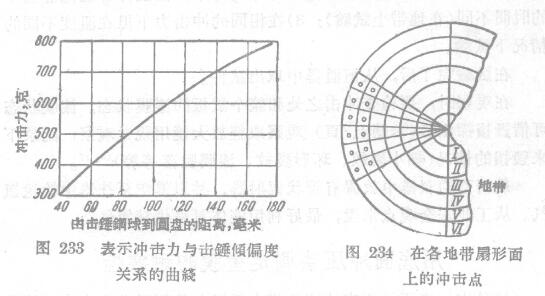

The relationship between the impact force of the hammer and the distance between the hammer steel ball and the national plate is determined by experiment. Make a mark on the rope (this mark indicates the throwing height and the impact force on the test board). The curve representing the relationship between the hammer impact force and the distance between the hammer steel ball and the disc is shown in Figure 233. With the help of the screw amplitude, the hammer can be moved up and down within a distance of 66 mm. Therefore, the impact on the disc is impacted on each zone (region). There are six of these strips; the distance between the strips is 11 mm. The distribution of the impact points on the disk is shown in Figure 234. The distribution of the zone and the sector, as well as the distribution of the impact points on the sector, can be recorded by a special indicator located on the flywheel 5 and the zone scale 9 (see Figure 232).

Apply the sample from both sides on a metal plate with a thickness of 0.4 to 0.5 mm. This metal plate is either a complete circle or a circle cut into six separate sectors. Divide the sample on each sector of the circle so that six painted surfaces (painted panels) can be tested simultaneously. Due to the movement of the disc and the hammer, 30 impacts are possible on each sector (see Figure 234). The test panel is mounted on a disc. A lining made of gray coat wool is placed between the disc and the test piece. When installing the national disk, pay attention to make the painted fan-shaped surface match the scale on the flywheel 5 (Fig. 232). After that, put solid carbon dioxide wells into the equipment box and cover the equipment. The temperature change can be seen on the resistance bridge indicator; start (turn on) the motor of the ventilator regularly. The temperature is maintained by the delivery of liquid oxygen, the delivery of which is regulated by a special device.

When the required temperature is adjusted and the specimen will be stored in the cryostat for a considerable period of time, turn the disc so that the indicator coincides with the first impact point on the fan-shaped surface of the first zone.

Pull the hammer to one side with the rope to the specified distance, and then strike. Turn the disc on the handle to connect the indicator to the next point on the fan, and perform the next impact. When the test in the first zone is finished, use the nut to raise the hammer by 11 mm, and test the rest according to the previous test method. Five zones (out of a total of six zones). The hammer strikes with a force of 300 grams to 800 grams.

The impact test can be carried out under the following conditions: 1) under constant temperature, the impact force of the hammer on different zones is different; 3) Test under the same impact force but at different temperatures. After the test, remove the test piece from the thermostat. (Related instrument: impact Tester)

During spot inspection, check the state of the paint film at the point of impact and the entire test panel. The state of the paint film can be inspected by a damage Detector (see page 317) or visually through a magnifying glass; record the damage (small cracks, ring cracks, peeling off of the paint film, etc.).

A tubular radiator is placed in the new instrument, and 1 oxygen is delivered to the instrument with good air. From the perspective of industrial safety, it is recommended to use liquid nitrogen instead of oxygen.