Determination of oil resistance of interior paint materials

Dip a painted metal plate measuring 50x100 mm into a cup filled with mineral oil.

The temperature of the oil, the depth of immersion and the length of immersion time are determined according to the technical conditions of the sample.

In order to determine oil resistance at high temperatures, the test needs to be carried out in a thermostat. After the test panel is soaked, take out the test panel, let it cool down, and wash off the oil residue with aviation gasoline.

After the time specified in the specification has elapsed, check the appearance of the paint film and its mechanical properties.

The test can also be performed as follows. Half of the film coated on an iron plate with a size of 40x130 mm is immersed in oil, and the other half is left in air. The test is carried out at 100~110°C within the specified time specified in the technical conditions. Another part of the panel was tested at room temperature. After the time specified in the technical conditions, remove the oil on the test plate, and then test the mechanical properties of the coating film in 1 fen of gold. In terms of mechanical properties, its hardness, elasticity and adhesion should not be inferior, and at the same time there should be no serious changes: blistering, pro-cracking, cracking and other phenomena. (Related instrument: drying time Tester)

Determination of oil resistance of exterior paint materials

Splash the painted test panel or a piece of material (according to the specification) with mineral oil. After the test time specified in the technical conditions, wash off the oil with aviation gasoline. The paint film should not show changes, stickiness, loss of elasticity, etc., and should meet the requirements of technical conditions in appearance.

Determination of oil resistance of insulating varnishes

In order to carry out the oil resistance test, the varnish to be tested must first be coated on two metal plates with an area of 100x50 mm and a thickness of 0.1-0.2 mm. (Related Instruments: Thickness Gauge)

After the paint film is painted and then dried (the drying temperature and time are specified in the standard or the technical conditions of the paint), the test panel is placed in the transformer oil (T0CT982- 43) for 24 hours. After 24 hours, take out the well of the test plate and wipe it clean with dry gauze. During the test, the transformer oil immersed in the test plate is divided into two equal parts, and one part is filtered through cotton wrapped in gauze.

The oil resistance of the varnish is expressed by the following indicators: 1) In the case of light machine passing through, comparing the filtered transformer oil and the unfiltered transformer oil in the test, no significant difference should be seen. Difference; 2) The surface of the paint film should not be wiped off by gauze after the test panel is removed from the oil; the gauze should not become black after wiping; 3) The surface of the paint film should remain smooth after the test; 4) The acid value of the oil after the test shall not exceed the value specified in the standard or specified in the varnish specification.

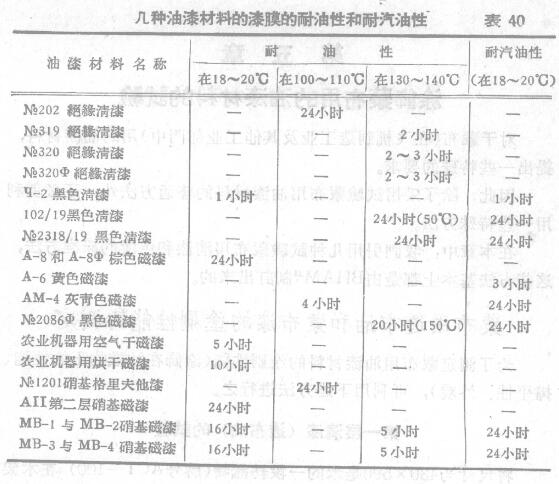

A varnish is considered oil-resistant if it meets all of the above characteristics. Table 40 lists the oil resistance and gasoline resistance data of several paint materials according to the existing technical conditions.