Impact resistance is a measure of how well a coating deforms under high-velocity loads. The impact resistance of a coating is related to its elongation, adhesion and hardness.

National standard analysis methods include: GB/T1732-93 "Determination of impact resistance of paint film". Factory analysis methods include: hammer impact method.

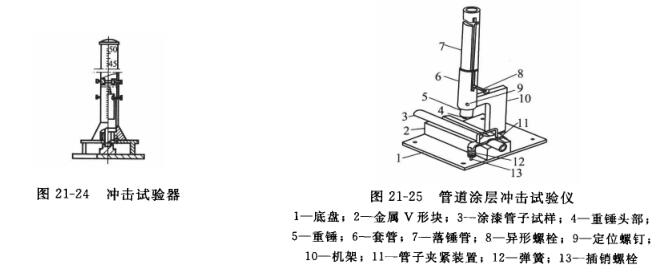

The instrument for testing the impact resistance of the coating is the impact Tester, as shown in Figure 21-24. The principle of the test is to drop a weight of a certain weight on the coating from different heights to deform the coating, and then check the degree of damage of the coating, expressed in cm.

Since the thickness of the sample substrate is directly related to the degree of deformation of the coating after being impacted, unless otherwise specified, when evaluating the impact resistance of a coating product, the substrate should be 50mmX120mm><(0.2~0.3 ) mm tinplate (tin-plated) plate, and when testing the impact resistance of putty, you can use 65mmX150mmX (0.45~0.55)mm thin steel plate, and put the dried paint sample on the surface when testing. Lift the heavy hammer to a certain height on the anvil at the lower part of the instrument, and then let the heavy hammer fall freely to impact the sample. The edge of the impacted part of the template shall not be less than 15mm, and the edge distance of each impact point on each template shall not be less than 15mm. Lift the weight, take out the sample plate, observe with a magnifying glass of 4 times, and judge whether the coating has cracks, wrinkles and peeling off. If there is damage, it is considered unqualified at this height; qualified. It should be noted that the sample must be close to the surface of the anvil during the test, so as not to affect the test results due to the jump of the sample during impact. The test should be carried out under constant temperature and humidity conditions, and the same test plate should be subjected to three impact tests. For pipeline coatings, due to the process of shipping, processing and installation, its ability to resist mechanical damage depends on its impact resistance. In order to test the impact resistance of the pipeline coating, the impact Tester device can also be used, as shown in Figure 21-25.

The measuring device also uses a weight with a fixed weight to drop from different heights to generate a point impact on the surface of the pipeline test, and then detect the cracking of the coating due to the impact, and the energy required for the coating to penetrate The value of is the impact resistance to be measured. In addition, in order to simulate the impact of backfilling after the pipe is placed in the ditch, a limestone drop test can also be used to measure the impact resistance of the pipe coating. That is to say, a certain weight of limestone of a specified shape is dropped onto the painted pipe sample through the launder, and the number of times required for the limestone to break through the coating and expose the metal is the result of the measurement.