Adhesion refers to the ability of the coating film and the surface to be coated or between the coating film and the coating film to adhere to each other, so it is also called binding force. It is very difficult to really measure the adhesion between the coating film and the substrate. At present, it can only be measured by indirect measurement, and the measured results not only reflect the adhesion, but also reflect other properties of the coating film, such as the coating film Impact strength, hardness, flexibility, etc.

At present, the adhesion to the coating film can be determined by the comprehensive performance measurement method and the peeling (off) method. Comprehensive performance testing methods include: cross-hatching method, cross-cutting method and circle drawing method; peeling testing methods include: twisting method and pulling method.

(1) Comprehensive performance testing method

①Cross grid method This method is relatively simple. Use a blade to cut a cross grid on the test plate as required, and use a magnifying glass to observe the peeling of the paint film to evaluate its adhesion. According to the national standard GB9286-88 "Paint and varnish, paint film cross-cut test" method for specific operations. As shown in Figure 8-7, it is a coating cross-cut instrument ( paint adhesion Tester ).

②The principle of the cross-cutting method is basically the same as that of the cross-hatching method, except that the graphics of the scratches are different.

③ circle method. The national standard GB1720-79 "Determination of Coating Film Adhesion" stipulates that it is evaluated and graded according to the integrity of the coating film within the range of the circular rolling line.

General provisions:

①Tin plate: 50mmxl00mmx(0.2~0.3)mm, used to make various test samples;

②4 times magnifying glass, used to observe the damage degree of the coating film;

③Brush, used to remove paint chips on the scratched surface;

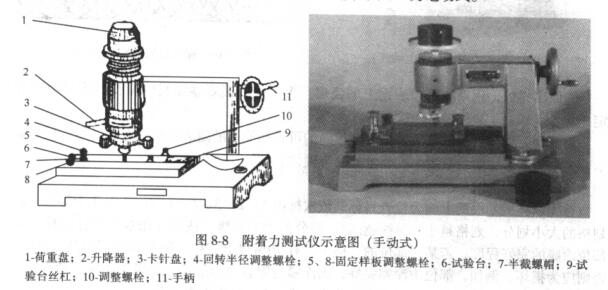

④ Coating film adhesion Tester, as shown in Figure 8-8 (manual type), and Figure 8-9 is an electric type.

Relevant part specifications on the Tester:

① The screw pitch of the test bench screw 9 is 1.5 mm, and its rotation is synchronized with the rotating needle, that is, while the rotating needle rotates, the screw drives the sample to move, forming continuous scratches.

② The rotating needle adopts Sanwu brand needle, and its no-load pressure is 200g.

③ Weights of different masses can be placed on the load plate 1 according to the situation, and the weights include 100g, 200g, 500g, and 1000g.

④The turning radius of the rotary needle is adjustable, and the standard turning radius is 5.25mm.

Determination method steps:

①Prepare paint film samples according to national standards.

② Check the needle of the rotating needle, if it is not sharp, it should be replaced.

③Adjust the radius of gyration to the standard value of 5.25mm.

④ Fix the model on the test bench 6, and place weights on the load plate 1 as appropriate, so that the rotating needle can scratch the paint film to the metal layer. (This shows that this method also reflects the hardness, flexibility and scratch resistance of the coating film when measuring the adhesion.)

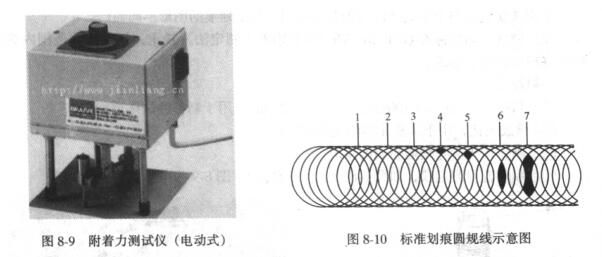

⑤ Evenly turn the handle 11 clockwise, the speed is preferably 80~l00r/:min, and the standard length of the circular rolling line scratches is (75±5)mm. Figure 8-10 is a schematic diagram of a standard scratch compass line.

⑥Take out the model, brush off the paint chips on the surface with a brush, and then use a magnifying glass to observe the damage of the paint film and grade it. .

At present, the adhesion Tester of the circle method adopts a wear-resistant needle with a high hardness and can be used for a long time. There is an automatic reporting signal prompting the needle tip to scratch and pierce the coating film device, which improves the detection accuracy.

Rating method:

First, take the upper side of the sample scratches as the inspection target, and mark 7 parts such as 1, 2, 3, 4, 5, 6, and 7 in turn (divided by the size of the grid, the smaller the grid, the higher the grade) , which is divided into seven levels. Use a magnifying glass to carefully check the integrity of the coating film at each part in order. If more than 70% of the "grid" of a certain part is intact, it is considered that the part is intact, otherwise it should be damaged. For example, if the coating film of part 1 is intact, the adhesion of the coating film is very good, and the rating is 1; if the part 1 is damaged, but the part 2 is intact, the adhesion is 2. By analogy, grade 7 has the worst adhesion.

⑦The test results are subject to the same level of at least two samples.

(2) Peeling test method

It mainly measures the work required to peel off the coating film from the surface of the object to be coated or the force required to pull a certain area of the coating film apart. Although this method is a step forward (direct measurement), it is not easy to use, and some require a long time, so the application is limited.