涂层的光泽度是指涂层表面把投射到其表面上的光线朝一个方向反射的能力。如果涂层表面越平整光滑,光线朝一个方向反射的能力就越强,光泽度也就越高。相反,则反射的光线杂乱,方向不一,光泽度低。涂层光泽度是反映车身涂装质量的重要指标之一。

涂层表面对光线反射的强弱,不但与涂层的表面状况有关,还与涂层对投射光线的反射量和透过量有关,不同的入射角,会得到不同的反光强度。因此,在对涂层进行光泽度测定时,需要选定好入射角。当然,在对两涂层光泽度进行比较时,也需要是在相同入射角情况下测定的结果比较。

由于光泽度的测量受测量环境和条件的影响很大,即在不同的光源下测量相同的涂膜表面光泽度,得出的结果是不相同的。光泽度的大小与环境光线的强弱有关。因此,对涂膜表面光泽度的测量是一个相对值,即将光泽计附有一个高光泽标准样板(黑玻璃)的光泽作为100%,被测定涂膜的光泽与标准样板作比较,用百分比表示。目前,测量涂膜光泽度的仪器有光电光泽计和投影光泽计两种,以光电光泽计为主。

光电光泽计的工作原理是:按一定角度将光投射到水平放置的被测涂膜表面上,通过透镜把反射的光线照射光电池,光电池将反射光线的强度转变为电流,再通过精密的检流计测定。

GB1743-79«漆膜光泽测定法»规定:采用固定角度(45°)的光电光泽计,以从漆膜表面正反射的光量与在同一条件下,从标准样板表面的正反射光量之比的百分数表示。一般规定和测定方法如下:

(1)一般规定

黑玻璃板(JG40_62):90mmX20mmX(2~3)mm;

光泽计:GZ_1型。

(2)测量方法

①按照GB1727-79«漆膜一般制备法»在黑玻璃板上制备漆膜。如果是清漆,应涂在预先涂有同类型的黑色无光漆的底板上。

②接通电源,使仪器预热10min。

③在仪器预热后,按下100%的量程选择钮。拉动样板夹,将黑色标准样板插入空隙内夹好。慢慢转动旋钮,使表针指示标准板所标定的光泽数,取出样板。

④插入被测样板,读取指示值,并与标准板的测试值进行比较,最后得出被测涂膜的表面光泽度。

If the gloss is lower than 70%, the 70% range button should be selected. Measure at three different positions of the sample, and the readings are accurate to 1%; the difference between the readings at each measuring point and the average value should not be greater than 5% of the average value; the result is the arithmetic average of the three-point readings.

After every five samples are measured, proofread with a standard sample. It should be noted that the standard template is the reference basis for measuring gloss, and its surface cannot be damaged during the process of measurement and storage, and the standard template should be replaced regularly. The measurement principle of the projection Glossmeter is: compare the gloss of the coating film with a set of standard samples with known glossiness, find the standard sample with the same amount of light reflection as the measured coating film, and use the gloss of the standard sample to represent the measured gloss. The gloss of the coating film.

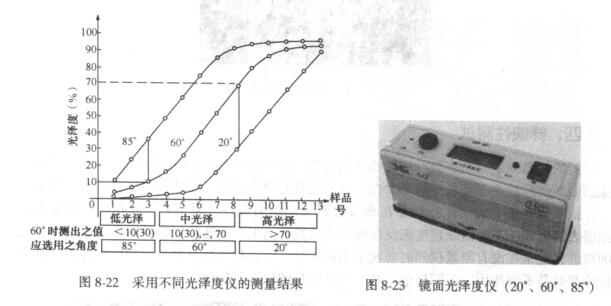

In order to improve the measurement accuracy of gloss, for coating films with different gloss ranges, Glossmeters with different angles should be used to measure. As shown in Figure 8-22, the measurement angles used for different gloss levels, the 60° gloss meter is used to measure the gloss coating film with a gloss level of 10%~70%; when the gloss level exceeds 70%, 20° should be used ° Gloss meter measurement; when the gloss is less than 10%, 85 ° gloss meter should be used for measurement.

As shown in Figure 8-23, it is the XCP, XCT specular float meter (20°, ., 85°three angles)