The distinctness of image is mainly used to detect the clarity of mirror objects reflected on the surface of the coating to define the decorative appearance of the coating. The sharpness of the surface of the coating film is related to the smoothness, fullness and gloss of the surface, and is a comprehensive indicator of the decorativeness of the coating film.

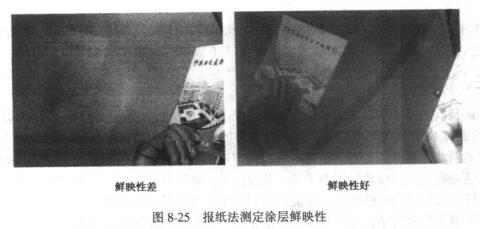

The newspaper imaging method (as shown in Figure 8-25) is to place (hold) a newspaper at a certain distance on the surface of the vehicle body, and observe the clarity of the writing on the surface of the coating to reflect the degree of distinctness of the coating. This method can qualitatively reflect the degree of vividness of the coating film, and it is also a method commonly used when there is no measuring instrument. However, this method is only a qualitative evaluation and cannot be used in quality arbitration. It is also not conducive to measuring information. storage and transfer.

In order to measure the distinctness of image of the coating film more accurately, two kinds of distinctness of image measuring instruments and measuring methods that have been used in CHINA are as follows.

1. Determination by portable distinct image Detector (PGD)

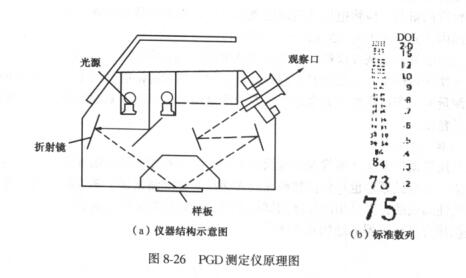

The measurement principle and standard sequence of the PGD measuring instrument are shown in Figure 8_26.

During the measurement, the standard digital board is irradiated with a light source, and the light reflected by the standard digital board hits the test sample board through two reflectors, and the reflected light of the test sample board is reflected by the two reflectors to the visual mirror, and then observed Observe the clarity of the sequence development on the standard digital board through the visual mirror, and record the DOI value corresponding to the sequence that can be read clearly. , 1.0, l.2, -1.5, 2.0, a total of 13 levels. The larger the value, the better the distinctness of image of the coating film, on the contrary, the worse the distinctness of image of the coating film. Figure 8-27 is the appearance of the coating film distinctness of image Tester. (Related instruments: gloss meter, illuminance meter)

Pay attention when measuring

① Before each measurement, the voltage should be adjusted to within the specified range to ensure that the light intensity of the light source in the measuring instrument is within the specified range (the illuminance of the light source is 1200lx, one lux).

② Calibrate the instrument with a standard mirror, and require the observer's eyesight to be able to clearly read the sequence corresponding to the DOI before using the instrument. That is, when measuring, what is observed is the clarity of the left column, not the clarity of the DOI value.

③ When measuring, the test sample should completely cover the measurement window of the instrument, so as not to affect the observation effect of the observer and ultimately affect the measurement accuracy.

2. Image resolution method

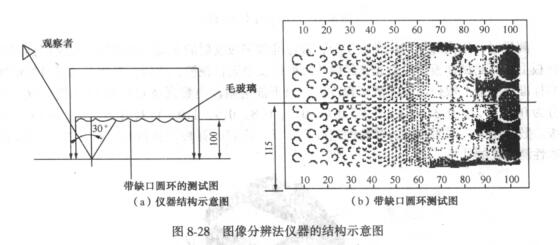

It is a method of measuring the distinctness of image of a coating film by mapping a ring with a notch on the surface of the coating film to be tested, and then evaluating the clarity of the image. The test principle is also based on the clarity of the image reflected on the standard test board on the surface of the coating film to be tested, to indicate the degree of distinctness of image of the coating film. Because the standard test boards used are different, the expression forms of the distinctness of image of the coating film are also different . Figure 8_28 is a schematic diagram of the image resolution instrument.

A 15w fluorescent lamp is installed in the light box, and there is a frosted glass in the middle to ensure the uniformity of illumination on the entire surface. On the frosted glass is placed a demo transparent film printed with notched circular graphics, and next to each column of images is There is a corresponding numerical value, which means distinctness of image, expressed by DI. There is also a standard black glass panel.

The test procedure for this instrument is

(1) Instrument calibration. Place a standard black glass plate under the instrument, the observer is positioned at a reflection angle of 30° and aligned with the central marking line of the test film, and adjust the observation distance until the image corresponding to DI=100 can be clearly seen.

(2) Based on this angle and distance, place the tested coating film on the bottom of the instrument to observe, find out a clearly visible image, and record the value on the side of the clear image, which is DI. If the position of the clear image is between the two values during the test, the middle value of the two values can be taken.

Similarly, this method of measuring the distinctness of image of the coating also has requirements for the operator's eyesight. The standard black glass plate and transparent film should be properly maintained and kept, and replaced according to the specified time to ensure the accuracy and precision of the test.