wrinkled

(1) phenomenon

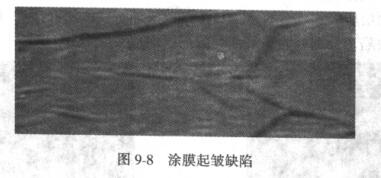

Uneven wrinkles appear on the surface of the coating film during the drying process of the coating. Usually, when the surface dries quickly, the surface area is large, resulting in uneven parallel linear and irregular linear wrinkles. Wrinkles vary in size, and some shrink in irregular patterns, as shown in Figure 9-8.

(2) Reason analysis

The main reason is that the drying rate of the surface of the coating film is too fast during the drying process of the oxidation-curing coating or when it is dried in the drying room, that is, the drying speed of the surface and the interior is different.

① The coating film is sprayed too thickly, resulting in different drying speeds on the surface and inside of the paint film.

② Poor dry environment. Such as low temperature, high humidity or excessive air flow over the surface after spraying or lack of ventilation.

③Insufficient drying time between layers.

④ The surface of the coated object is polluted by wax, engine oil or butter, which causes the drying speed in the film to be too slow.

⑤ Excessive use of slow drying agent and improper selection of thinner.

⑥ The "dirty gas" in the drying room (usually caused by poor ventilation or burning oxides).

⑦ Some synthetic resin baking varnishes are dried for too long, and then baked after the surface is dry, which is prone to small wrinkles. (Related instrument: oven)

⑧ On the old nitro paint film, after re-spraying with polyurethane topcoat, if it is repaired again, it is prone to wrinkle phenomenon (different shrinkage rate on the outside and inside).

(3) Preventive measures

①The surface to be coated should be effectively cleaned before spraying.

② Avoid spraying too thickly, and it is better to use dry spraying in the first pass.

③ Improve the spraying and drying environment, increase the temperature, and strengthen the air flow control (in the spraying room).

④Leave sufficient drying time between each coat. Use an approved thinner.

⑤ Check the pollution degree of the air in the drying room, make corrections or replace the fuel.

⑥Synthetic resin baking paint should be dried after the specified time.

⑦ Use an anti-wrinkle agent, such as modified alkyd resin paint, which is slightly thicker and easy to wrinkle during drying. Add a small amount (about 5%) of amino resin as an anti-wrinkle agent, and spray with a thickness of more than 40 μm for one time. Dry and wrinkle free.

(4) Remedy

① In the case of light defects, after the paint film is completely dry, effectively polish to remove all wrinkles and respray.

② When the defect is serious or slow drying due to pollution, it should be removed to the substrate and repainted.

bubble

(1) phenomenon

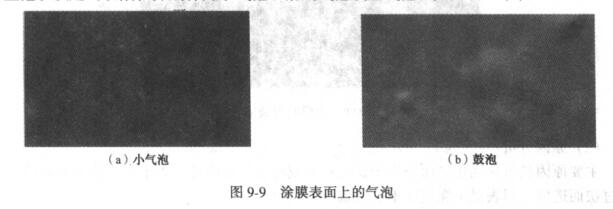

During the coating process, the surface of the coating film is bulging in the form of bubbles, or there are bubbles in the coating film. This defect is prone to occur during the drying process. The bubbles caused by stirring or the bubbles generated by the evaporation of the solvent, which remain in the coating film without disappearing during the coating film formation process, are collectively referred to as bubbles. As shown in Figure 9_9(a).

Due to the absorption or containment of moisture, solvent or gas by the substrate or primer layer, the defects of the coating in the form of bubbles and arches during drying (especially drying) are called water bubbles, solvent bubbles or air bubbles, respectively. As shown in Figure 9_9(b).

(2) Reason analysis

The main reason is that there is gas mixed in the coating film, or there is a liquid that produces gas at the bottom of the coating film.

① Thinner volatilizes quickly, the viscosity of the paint is high, and it is difficult for the solvent and thinner in the film to escape, resulting in bubbles.

② The drying time is short, and the temperature rises too fast when the coating is dried.

③Substrate (such as wood, fiberglass board), primer (especially putty layer) or coated surface contains (or remains) solvent, moisture or gas.

④The gas mixed into the paint during stirring is not released before painting, or mixed with air during brushing and scraping.

⑤ The putty applied at one time is too thick.

⑥ The compressed air used for spraying has not been dried. (Related instruments: Air Compressor)

(3) Preventive measures

①Use the thinner matched with the coating, the viscosity should be selected according to the coating method, and should not be too high.

②Dry according to the specified time, and the temperature should not rise too fast when the coating is dried. (Related instrument: drying time Tester)

③Substrate, bottom layer or coated surface should not contain moisture, solvent and gas, and should be dry and clean.

④ After the air bubbles in the paint are released, paint again (when brushing or scraping).

⑤Before spraying, the remaining moisture and liquid in the car body, grooves, etc. should be effectively removed and kept dry and clean.

(4) Remedy

Bubbles are a destructive defect of the coating film, which can only be eradicated and the surface prepared again; putty and paint spraying.