A polarimeter is an instrument used to detect the optical rotation of a substance, mainly through the detection of the optical rotation of the measured object to analyze the concentration, content and purity of the substance.

1. The structure and principle of the instrument

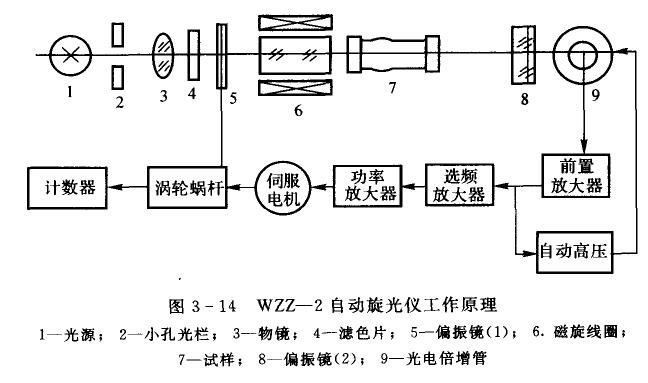

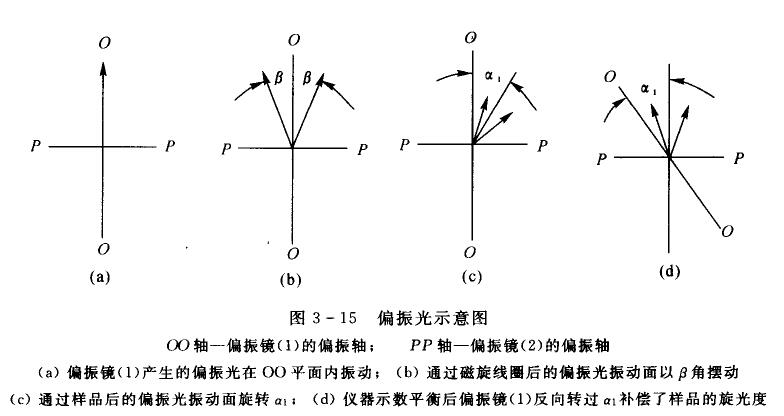

WZZ-2 automatic polarimeter adopts the principle of photoelectric detection and automatic balance to carry out automatic measurement. Measurement results are displayed digitally. It can also adapt to low optical rotation samples that are difficult to analyze by visual polarimeter. Therefore, it is widely used in various fields such as medicine, food, organic chemical industry and so on. The instrument uses a 20W sodium lamp as the light source, and consists of a small hole diaphragm and an objective lens to form a simple point light collimator (see Figure 3-14). The parallel light is transformed into plane polarized light by the polarizer (1), and its vibration plane is 〇〇 (see Figure 3-15(a)), when the polarized light passes through the magnetic gyro coil with the Faraday effect, its vibration plane produces a 50Hz β-angle reciprocating swing (see Figure 3-15(b)), and the light After the polarizer (1) is projected onto the photomultiplier tube, an alternating electric signal is generated.

How to use the instrument

(1) Operation method

1) Insert the power plug of the instrument into the 220V AC power supply (requires the use of an AC electronic voltage stabilizer (1KVA)) and ground the ground pin reliably.

2) Turn on the power switch, then the sodium lamp should be turned on, and the sodium lamp needs to be preheated for 10 minutes until the light is stable.

3) Turn on the light switch. If the sodium lamp goes out after the light source switch is turned on, then turn the light source switch up and down repeatedly 1 or 2 times to make the sodium lamp light up under direct current, which is normal.

4) Turn on the measurement switch, and the machine is in the state of being tested.

5) Put the test tube filled with distilled water or other blank solvents into the sample chamber, close the lid, and press the reset button after the reading is stable. If there are air bubbles in the test tube, let the air bubbles float on the convex neck first; wipe the misty water droplets at both ends of the transparent surface with a soft cloth. The test tube nut should not be over-tightened, so as not to generate stress and affect the reading. Pay attention to the position and direction of the mark when placing the test tube.

6) Take out the test tube, inject the sample to be tested into the test tube, put it into the sample chamber in the same position and direction, and cover the box cover. The instrument readout window will display the optical rotation of the sample.

7) Press the retest button one by one, repeat the reading several times, and take the average value as the measurement result of the sample.

8) If the sample exceeds the measuring range, the instrument stops at ±45. At this time, take out the test tube, open the box cover and press the zero return button inside the box, and the instrument will automatically return to the zero position.

9) After using the instrument, turn off the measurement, light source, and power switches in sequence.

Notice

1) When measuring dark samples, when the transmittance of the tested sample is low, the repeatability of the readings of the instrument will decrease, which is a normal phenomenon.

2) When the sodium lamp cannot be used due to failure of the DC power supply system, the instrument can also be tested under the condition of the sodium lamp AC power supply, but the performance of the instrument may be slightly reduced. .3) When a sample with a small angle (less than 0.5°) is put in, the display may change. At this time, just press the retest button, and a new number will appear.

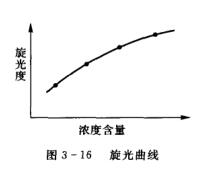

(2) Determination of concentration or content. Dilute the standard or reference sample of known purity into several samples with different concentrations according to a certain ratio, and measure the optical rotation respectively. Then take the concentration on the horizontal axis and the optical rotation on the vertical axis to draw an optical rotation curve (see Figure 3-16). Generally, optical rotation curves are made into look-up table form by arithmetic interpolation method.

When measuring, the optical rotation of the sample is measured first, and the concentration or content of the sample is found from the optical rotation curve according to the optical rotation.

When measuring, the optical rotation of the sample is measured first, and the concentration or content of the sample is found from the optical rotation curve according to the optical rotation.

The optical rotation curve should be done with the same instrument and the same test tube, and attention should be paid to the measurement.

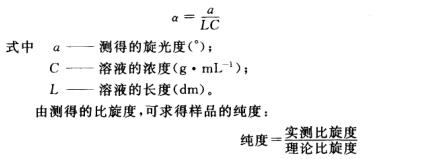

(3) Determination of specific rotation purity. First prepare the solution according to the concentration specified in the Pharmacopoeia, measure the optical rotation according to the law, and then calculate the specific rotation (α) according to the following formula:

(4) Determination of international sugar content. According to the international sugar content standard, it is stipulated that 26g of pure sugar is used to make 100mL solution, and it is measured with sodium light at 20°C in a 200mm test tube. Its optical rotation is ten 34.626°, and its sugar content is 100.

3. Instrument repair and maintenance

(1) The instrument should be placed in a dry and ventilated place to prevent moisture erosion. Try to use the instrument in a working environment of 20°C. Move the instrument with care and avoid vibration.

(2) If the light source (sodium lamp) is dusty or damaged, you can open the case to clean or replace it.

(3) The friction resistance of the mechanical part increases, you can open the rear door panel, and add a little oil to the gear and worm gear.

(4) If you find that the instrument stops or other components are damaged, you should check in detail according to the electrical schematic diagram or notify the manufacturer, and the maintenance personnel of the factory will carry out the inspection.

(5) After turning on the power, if the sodium lamp does not light up, check the fuse.