1. What is the definition of apparent density of powder coating? How to measure apparent density?

1. What is the definition of apparent density of powder coating? How to measure apparent density?

(1) Definition

Apparent density refers to the mass of powder coating per unit volume, expressed in g/c㎡.

(2) Instrument

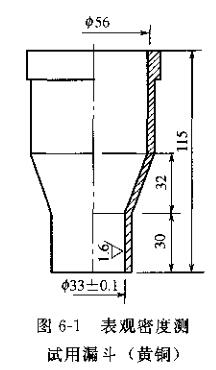

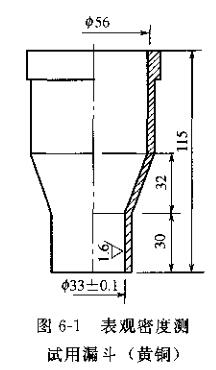

See Figure 6-1 for the funnel, which is made of metal.

Graduated cylinder: the volume is 100mL10.5mL, the inner diameter is 40mm ± 5mm; it can be made of metal, and the inner surface is polished.

Sealing plate: The size and shape should be suitable for sealing the lower opening of the funnel.

Daping: Sensitivity 0.lg.

(3) Test procedure

Place the funnel vertically, with the true lower opening directly above the measuring cylinder, with a distance of 25-30mm, and the two are coaxial.

Loosely trace the powder to be tested, and measure out 110-120mL (more if necessary) powder sample with a measuring cup. Cover the lower opening of the funnel with a sealing plate, and pour the powder sample into the overflow funnel.

Quickly let go of the sealing plate to allow the powder sample to flow into the meter. If necessary, a small stick can be used to loosen the powder sample in the funnel so that it can flow out dynamically.

When the measuring cylinder is full, use a ruler to level the surface, and use a balance to weigh the mass of the powder in it, accurate to 0.lg.

2. What is the definition of powder coating bleeding? How is outflow measured?

2. What is the definition of powder coating bleeding? How is outflow measured?

(1) Definition

The outflow property refers to the time for a powder of specified quality to flow out from a funnel of specified specifications, and the unit is expressed in s.

(2) Equipment

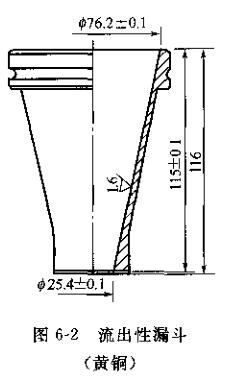

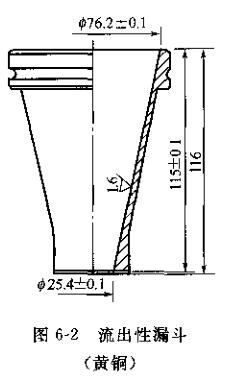

Funnel: See Figure 6-2, and the mechanism for placing the funnel vertically.

Balance: Sensitivity 0.lg.

Stopwatch or other timer.

(3) Test procedure

Put the powder sample on the paper to make it loose and not agglomerate, and weigh out 100g of the powder sample. Place the funnel vertically, and seal the lower opening with your hands or a closed slat. Gently pour the weighed powder sample into the funnel.

Quickly release the lower mouth and start the timer at the same time, let the powder flow out by itself, and stop the timer when the powder stops flowing out.

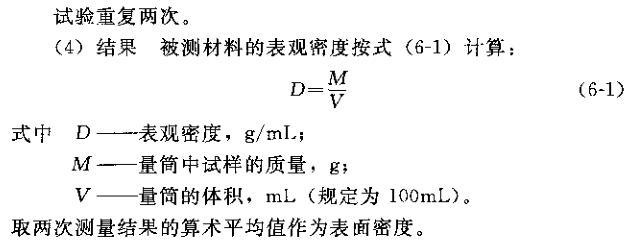

(4) Results

Take the arithmetic mean of the three measured values as the result, the unit is s, accurate to 0.5s. If the powder sample does not flow out, it should also be explained.

1. What is the definition of apparent density of powder coating? How to measure apparent density?

1. What is the definition of apparent density of powder coating? How to measure apparent density? 2. What is the definition of powder coating bleeding? How is outflow measured?

2. What is the definition of powder coating bleeding? How is outflow measured?