(1 Scope

This standard specifies the method for determining the density of powder coatings by the liquid displacement pycnometer method. This method is based on the determination of the mass and volume of the sample.

The specified apparatus is relatively inexpensive, but the liquid displacement pycnometer method is prone to erroneous results. This is because: first, the powder coating swells in contact with the replacement liquid used, and second, the replacement liquid cannot completely replace the air between the powder coating particles. The liquid displacement method is relatively slow to operate and is less accurate than the gas specific gravity method specified in IS08130-2. Therefore, it can only be used under the condition that the same results as the gas comparison pycnometer method can be obtained.

(2) Principle

According to IS0787-10, use a liquid that can completely wet the test product without causing it to swell or dissolve, and determine the density of the powder coating by the liquid displacement pycnometer method.

(3) Material

①Water: Water that meets the requirements of IS03696, freshly boiled and cooled, with at least grade 3 purity.

②Displacement liquid: any suitable fat lamp or mixture of fat diameters, the boiling point of which is within the range of 80~140℃.

n-Heptane has proven suitable in many cases for measuring the density of thermosetting powder coatings. However, if it is found that there is an interaction between n-heptane and the test product and its components, a suitable alternative liquid should be selected.

③Acetone: analytically pure.

(4) Instrument

①Pycnometer: conform to IS0787-10.

②Vacuum pump: connected with rubber pressure tube.

③ Balance: The load capacity is 200g, and it can be weighed to 1mg or more accurately.

(5) Sampling

Follow the method described in 1S0842 to take a representative sample of the test product.

(6) Operation steps

The parallel determination was completed under the condition of weighing accurate to 1 mg at 23°C±0.5°C.

①Determination of the density of the displacement liquid: Weigh an empty and clean pycnometer, fill it up to the mark with the displacement liquid, and weigh again. Empty the pycnometer, wash the empty pycnometer separately with 3 parts of acetone, and dry the pycnometer under vacuum conditions. Refill the pycnometer with water and weigh again.

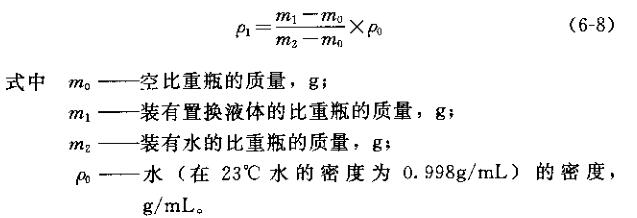

Calculate the density of the replacement liquid at 23°C by formula (6-8), ρ 1 , expressed in g/mL:

②Determination of the density of the powder coating: Wash the empty pycnometer three times with acetone and dry it under vacuum. Put 3~4g test sample into the pycnometer and weigh again. Add sufficient replacement liquid to adjust the humidity of the sample, and make the liquid cover the sample. Connect the open pycnometer to the pressure tube of the vacuum set. Reduce the pressure of the pycnometer to a maximum of 1.2 kPa and shake until air no longer escapes from the powder/liquid mixture. Carefully raise the pressure in the pycnometer to atmospheric pressure, then fill the pycnometer with displacement liquid to the mark. Be careful not to stir the settled powder. Care should be taken when filling to avoid powder retention in the neck of the pycnometer. Weigh the pycnometer that has filled the material again.

(7) Expression of results

① Calculation Use the formula (6-9) to calculate the density of the powder coating at 23°C, expressed in g/mL: