Microscopic examination of dispersion is also a commonly used method.

Microscopic assays are valuable methods for examining coarsely dispersed systems. When using this method of determination, both correct preparation of pigment samples and familiarity with inspection techniques are the basic conditions for obtaining accurate data.

When carrying out the qualitative determination of pigment dispersion, in the most convenient case, only a small amount of pigment can be dispersed into 1~2 drops of binder (water, oil, etc.), and then a small amount of this suspension can be taken Place on a microscope slide and cover with a cover glass. When observed under a microscope, it is possible to measure the fineness of the pigment particles and how small one pigment is compared to another.

Quantitative determination of dispersity can be done in several ways. Now introduce a method that gives good results.

When using this method to measure the dispersion, it is necessary to weigh 0.1-0.5 grams of the tested pigment (the specific weight depends on the specific gravity of the pigment and the grinding fineness) and place it in a cylinder with a volume of 10 ml, and then inject it into the cylinder. To share the liquid, shake the formed suspension well for 1/4% hour. The liquid chosen depends on the specific gravity and solubility of the pigment being tested. In order to determine the degree of dispersion of various pigments, bleached linseed oil, glycerin, mineral oil, distilled water, etc. must be used). Immediately after shaking the main body, use a micropipette to suck out 0.01 ml of the suspension from the cylinder, dilute it to 1 ml with the same liquid, and shake for another 1/4 hour; The centerpiece of the glass computing room. Cover the computing chamber with a cover glass and let the wells sit for 1–12 h to allow all particles to settle at the bottom of the chamber.

Good results can only be obtained when there are ]0~20 particles in a room field. If the number of particles in a room field does not exceed 3, the obtained results cannot be considered very reliable. Put the counting chamber prepared in this way under a microscope, and measure the diameter of the particles when magnified 550 times with the help of an eyepiece micrometer (micrometer eyepiece), and calculate the number of various particles with different sizes.

The calculation and measurement of particle diameter are carried out in various parts of the calculation room. The results obtained are expressed as a calculated percentage of the total number of pigment granules.

We know that the effectiveness of ordinary microscopes is very limited. Its magnification does not exceed ]500~2000 times. When ultraviolet light is used as the light source, it can be magnified to 3000~3500 times. However, in practical applications, it is rare to magnify more than 1000 times, because it is impossible to see any new details from the image when magnified to a larger multiple.

If an electron microscope 42 is used, the magnification may be tens of thousands or even hundreds of thousands of times.

The first electron microscope in the Soviet Union was created by Academician Lebedov.

The function of the electron microscope 42 is based on the diffraction phenomenon of electrons. In an electron microscope, the flow of electrons acts optomechanically, and the lens is an electric or electromagnetic field that converges or diverges the flow of electrons.

The electron beam passes through the object to be inspected, and different electron diffusions are obtained in different parts of it. The image of the object to be inspected can be obtained on the light receiving plate or on the photographic film.

The inspected object in the electron microscope should basically meet the following conditions: it is transparent to the electron flow, it will not be damaged in a high vacuum and it will not be damaged under the action of the electron beam.

The sample for inspection can be applied on the membrane or on the bottom surface (bottom film). Finely dispersed substances, powders (various pigments), and suspensions (various paints) are applied to the bottom surface (base film). The bottom film is a film of nitrocellulose or polyvinyl acid with a thickness of 200~300A. This film is formed by dropping a not too concentrated solution (1~1.5%) of the resin in acetic acid synthesis on the water surface. made. The droplets are spread out on the surface of the water, and when the film is dry, a few drops of the substance to be tested (suspension or other) are applied to the film.

In order to increase its contrast, a layer of heavy metal (gold, chromium) powder is removed from the prepared object.

When preparing the object to be inspected, very cleanliness is the basic and important condition in the electron microscope. For example, to inspect the surface of metal, resin, and paint film, an indirect method must be used. The most satisfactory of this indirect method is the replication method, which is to remove the replica surface film from the surface of the inspected object, and then examine it in the electron microscope. Observe now.

In order to study the structure of rubber materials, Dojadekin et al. have proposed a new method, which is a new method of using gelatin to remove the collodion film (300~500A) without any film change on the surface of the object to be inspected. . The process of this method is as follows. Freeze the rubber sample (rubber and carbon black) in liquid nitrogen and sprinkle 1-2 drops of 1% collodion solution on the surface of the sample (1-2 cm2). Add a drop of gelatin solution to the formed collodion film imitating the surface structure of the glue. After the solution dries, a thick gelatin film is formed which is easy to connect with the collodion film, and it is easy to remove the latter (film) iron from the surface of the inspected object.

The thus prepared gelatin film with a collodion film was placed in hot water. The gelatin is dissolved, and the collodion film floats on the water surface, and is picked up with a clip (net) and inspected in an electron microscope. In order to improve the visibility of the imitation film, the method of deepening the color by mistake has been used.

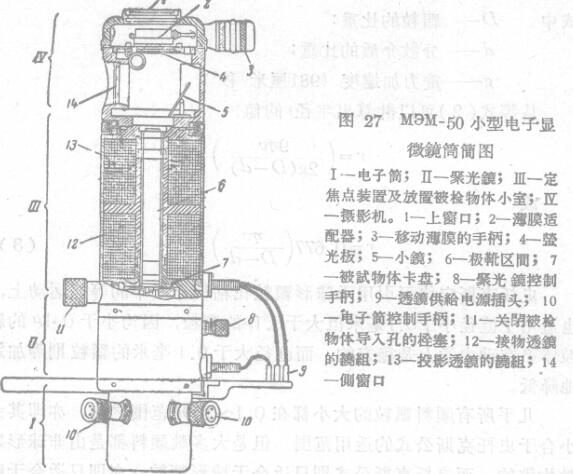

Akimov. With the help of an electron microscope, he studied the structure of the protective film on the iron surface, and the structure of the aluminum-treated film on the cathode when magnified from ]8000 times to 45000 times. Shown on Fig. 27 is the simple diagram of the M3M-50 miniature electron microscope tube designed by Zajchev and Lebakov et al.

Unfortunately, electron microscopy has not been widely used in the inspection of paint materials. For example, when studying the structure of pigments, a very low-concentration suspension of pigments in a film-forming substance (Vitamin) can be used (the film-forming substance 1 used can form a nearly transparent film after drying. ).