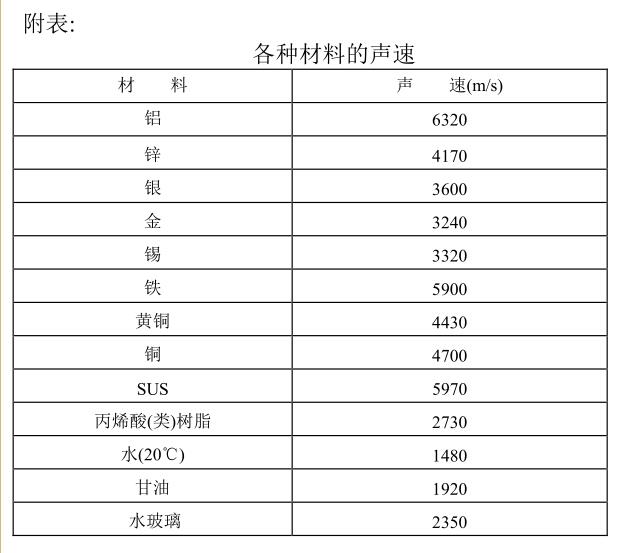

1 Overview

1.1 Scope of Application

TT130 intelligent ultrasonic Thickness Gauge adopts the principle of ultrasonic measurement, which is suitable for the measurement of the thickness of various materials that can make the ultrasonic wave propagate at a constant speed and can be reflected from its back.

The instrument enables accurate measurement of all kinds of plates and all kinds of machined parts, and another important aspect is that it can monitor the various pipes and pressure vessels in the production equipment and monitor the degree of thinning of them after corrosion during use. It can be widely used in petroleum, chemical industry, metallurgy, shipbuilding, aviation, aerospace and other fields.

1.2 Rationale

The principle of ultrasonic thickness measurement is similar to that of light wave measurement. The ultrasonic pulses emitted by the probe reach the object to be measured and propagate through the object, and when they reach the material interface, they are reflected back to the probe to determine the thickness of the material by accurately measuring the time it takes for the ultrasonic waves to propagate through the material.

1.3 Basic configuration and the name of each part of the instrument

1.3.1 Basic Configuration:

Main unit: 1 set

1 5PΦ10 probe

Couplant 1 bottle

1.3.2 Options:

1 5PΦ10/90° probe

SZ2.5P probe 1 pcs

1 7PΦ6 probe

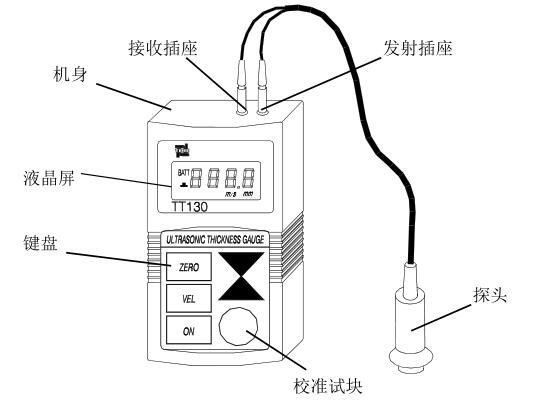

1.3.3 Name of each part of the instrument (see figure below)

2. Performance indicators

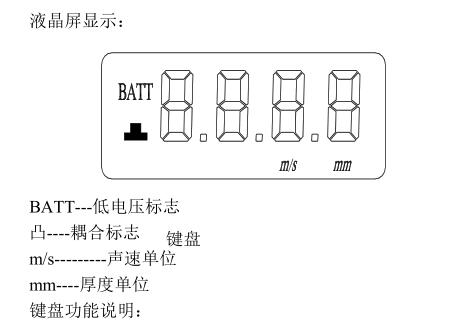

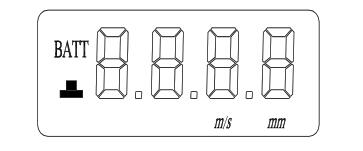

Display mode: four-digit LCD display

Smallest unit of display: 0.01mm

Operating frequency: 5MHz

Measuring range: 1.2mm~225.0mm (steel)

Lower pipe measurement limit: Φ20mm×3.0mm

Measurement error: ± (1%H+0.1)mm, H is the actual thickness of the measured object

Sound velocity adjustment range: 1000m/s~9999m/s

Sound velocity measurement of known thickness: when the measurement range is 1000m/s~9999m/s, and the thickness of the test block is ≤20mm, the sound velocity measurement accuracy is ±1mm/h×100%; When the thickness of the test block > 20mm, the sound velocity measurement accuracy is ±5%

Operating temperature range: 0°C~40°C

Power supply: 2 x No. 5 dry batteries

Power consumption: Operating current<20mA (3V)

Dimensions: 126mm× 68mm×23mm

Weight: 170g

3 main functions

●Automatic calibration of the zero point, which can correct the system error

●Automatic linearity compensation, using computer software to correct the nonlinear error of the probe in the whole range to improve the accuracy.

●The upper and lower adjustment keys can be used to quickly adjust the sound velocity and thickness, and the thickness storage unit can be quickly queried.

●Coupling state prompt: Provide a coupling flag, and you can know whether the coupling is normal by observing its stable state.

●Ten thickness values can be stored, and the data will not be lost after shutdown, which brings convenience to high-altitude and field work.

●Sound velocity measurement function: directly measure the sound velocity according to the thickness of the sample, avoiding the trouble of checking the table or conversion.

● Sound velocity of five different materials can be stored.

●Low voltage prompt.

● Automatic power off: The timed automatic shutdown will help you turn off the power.

●The closed operation of the whole key membrane ---- prevent oil pollution and improve the service life.

4 Measurement steps

4.1 Measurement preparation

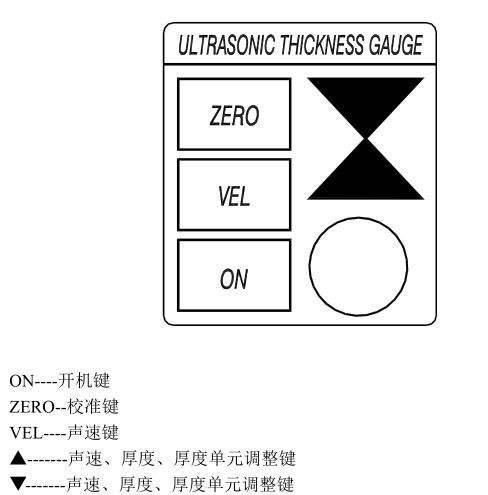

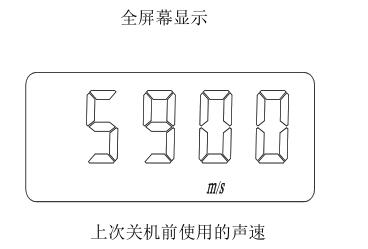

Insert the probe plug into the host probe socket, press the ON button to power on, and the full screen display will display the sound velocity used before the last shutdown for a few seconds, as shown in the figure below, and the measurement can be started.

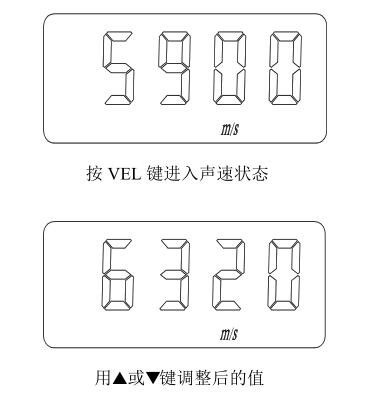

4.2 Adjustment of sound velocity

If the current screen is displayed as a thickness value, press the VEL key to enter the sound velocity state, and the screen will display the current soundspeed the contents of the storage unit. With each press, the velocity storage unit changes to cycle through five velocity values. If you want to change the contents of the currently displayed sound velocity unit, use the ▲ or ▼ keys to adjust it to the desired value, and save this value to the unit at the same time.

4.3 Calibration

Calibration should be performed after each probe replacement and battery replacement. This step is critical to ensure the accuracy of the measurement. Repeat as many times as necessary.

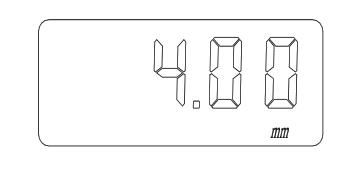

After adjusting the sound speed to 5900m/s, press the ZERO button to enter the calibration state, and the screen displays:

Apply couplant to the random test block, couple the probe to the random test block, and the horizontal lines displayed on the screen will disappear one by one until the screen shows 4.00mm, that is, the calibration is completed. Then turn to the measurement state, measure the random test block, if the indication error exceeds the measurement error of the instrument, it needs to be calibrated again until the indication error is within the measurement error range.

4.3 Measure the thickness

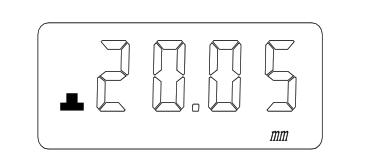

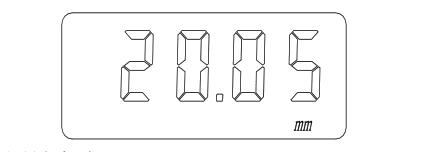

Apply the couplant to the measured place, couple the probe with the measured material to measure, and the screen will display the thickness of the measured material, as shown in the figure:

Description: When the probe is coupled to the material being measured, the coupling flag is displayed. If the coupling sign flashes or does not appear, the coupling is not good. When the probe is removed, the thickness value is maintained and the coupling flag disappears. As shown in the figure:

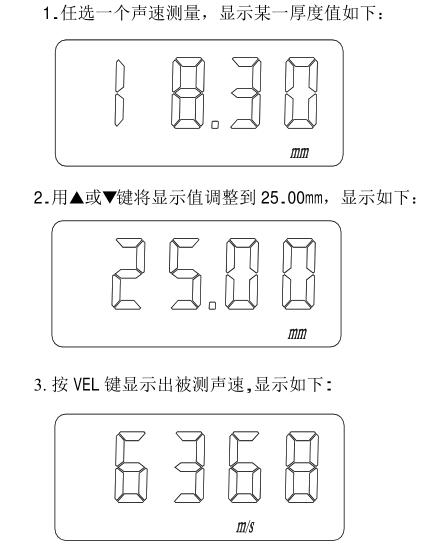

5. Measure the speed of sound

If you want to measure the sound velocity of a material, you can measure the sound velocity with a test block of known thickness. First, measure the test block with a vernier caliper or micrometer to accurately read the thickness value. Couple the probe with the known thickness test block until a thickness value is displayed, remove the probe, use the ▲ or ▼ key to adjust the display value to the actual thickness value, and then press the VEL key to display the measured sound velocity, and the sound velocity is stored in the current sound velocity storage unit. Sound velocity measurement requires the selection of a test block of sufficient thickness, with a minimum wall thickness of 20 mm.

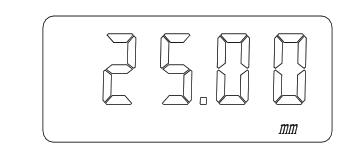

For example, if you want to measure the sound velocity of a material with a thickness of 25 mm, do the following:

1. Select any sound velocity measurement to display a certain thickness value as follows:

6. Thickness value storage

6.1 Storage

Press and hold the VEL key, and then press the ZERO key to enter the thickness storage state, display a certain thickness storage unit number, at this time, you can use the ▲ or ▼ key to set the required unit (use the ▲ or ▼ key to cycle through the display of 0~9 units). At the same time as the thickness is measured, the measured value is stored in the setting unit. Each time a new value is measured, the old value is refreshed, and the unit records the last measured value. Press the VEL key to exit the thickness storage state.

6.2 View Stored Contents

Press and hold the VEL key, then press the ZERO key to display the current thickness storage unit number, use the ▲ or ▼ key to find the unit you want to view (use the ▲ or ▼ key to cycle through the display of cell 0~9), and operate again to display the content of the unit. At this point, the measurement can also store the newly measured value in the unit. Press the VEL key to exit the thickness storage state.

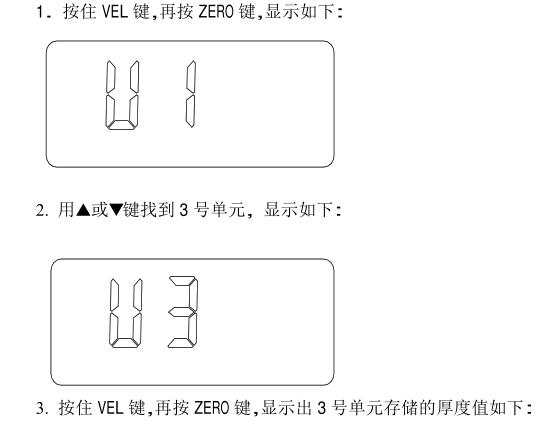

Example: Check the thickness value stored in unit 3

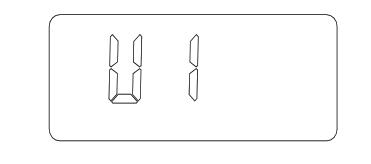

1. Press and hold the VEL key, and then press the ZERO key, it will be displayed as follows:

4. Press the VEL key to exit the thickness storage state. If you do not press the VEL key to exit the thickness storage state, the remeasured thickness value will refresh the old value of the element.

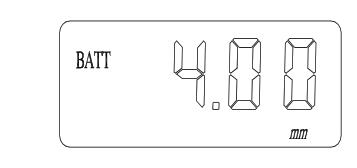

7. Low voltage indication

If the BATT logo is displayed on the screen, it means that the battery voltage has dropped and the battery should be replaced in time before continuing to use.

8. Automatic power off

If nothing is done within two minutes, it will automatically shut down.

9. Measurement technology

9.1 Clean the surface

Before measuring, all dust, dirt and rust should be removed from the surface of the measured object, and paint and other covering materials should be removed.

9.2 Reduce roughness

Excessively rough surfaces can cause measurement errors or even no readings on the instrument. Before measuring, the surface of the measured material should be smoothed as much as possible, and grinding, throwing, filing and other methods can be used to make it smooth. High-viscosity couplants can also be used.

9.3 Rough machining surface

The regular grooves caused by the rough machined surface (such as lathes or planers) can also cause measurement errors, and the method of making up for them is the same as 9.2, and the angle between the transducer crosstalk separator plate (through the thin metal layer in the center of the bottom surface of the probe) and the slots to be measured is adjusted, so that the separator plate and the slots are perpendicular or parallel to each other, and the minimum value in the reading is taken as the measurement thickness, which can achieve better results.

9.4 Measure cylindrical surfaces

For the measurement of cylindrical materials, such as pipes, oil drums, etc., the importance of selecting the angle between the transverse barrier plate of the probe and the axis of the material to be measured is not to be overstated. To put it simply, the probe is coupled to the material to be measured, the transducer crosstalk barrier plate is parallel or perpendicular to the axis of the material being measured, and the probe is slowly shaken perpendicular to the axis of the material being measured, and the readings on the screen will vary regularly, selecting the minimum value in the reading as the exact thickness of the material.

The criterion for selecting the angle direction of the intersection of the probe crosstalk separator plate and the axis of the measured material depends on the curvature of the material, the pipe with a larger diameter, the probe crosstalk separator plate is perpendicular to the axis of the tube, and the pipe with a smaller diameter is selected to be parallel and perpendicular to the axis of the tube, and the minimum value in the reading is taken as the thickness of the measurement.

9.5 Composite shape

The method described in 9.4 can be used when measuring materials with composite profiles, such as at the elbow of a pipeTo perform a secondary measurement, read the two values of the transducer crosstalk compartment plate perpendicular to the axis and parallel to the axis, the smaller of which is the thickness of the material at the measurement point.

9.6 Non-parallel surfaces

In order to obtain a satisfactory ultrasonic response, the other surface of the material to be measured needs to be parallel or coaxial to the surface being measured, otherwise it will cause measurement errors or no readings at all.

9.7 Influence of temperature of materials

The thickness of the material and the ultrasonic propagation speed are affected by the temperature, if the measurement accuracy is required to be high, the test block comparison method can be used, that is, the test block of the same material is measured under the same temperature conditions, and the temperature compensation coefficient is obtained, and the measured value of the measured workpiece is corrected with this coefficient.

9.8 Large attenuation materials

For some materials such as fibers, porous, and coarse-grained materials, they can cause a large amount of ultrasonic scattering and energy attenuation, resulting in abnormal or even no readings (usually abnormal readings are less than the actual thickness), in which case the material is not suitable for testing with this thickness gage.

9.9 Reference Test Blocks

In order to calibrate the instrument, the TT130 ultrasonic Thickness Gauge casing is equipped with a steel test block with a thickness of 4.00mm, and the calibration method is shown in 4.3. For accurate measurements of different materials under different conditions, calibration requirements are often not met by randomly configured test blocks alone. The closer the calibration block is to the material being measured, the more accurate the measurement will be, and the centering reference block will be a set of test blocks of different thicknesses of the tested material, which can provide instrument compensation correction factors (such as microstructure of the material, heat treatment conditions, particle direction, surface roughness, etc.). In order to meet the requirements for maximum accuracy measurements, a set of reference test blocks will be important.

In most cases, satisfactory measurement accuracy can be achieved using a reference block of the same material and a similar thickness as the material being measured. Take the uniform material to be measured with a micrometer and use it as a test block.

For thin materials, when its thickness is close to the lower limit of the probe, the test block can be used to determine the exact lower limit (the lower limit of measurement for steel is 1.2 mm). Do not measure materials below the lower limit thickness. If a thickness range can be estimated, then the upper limit of the thickness of the test block should be selected.

When the measured material is thick, especially the alloy with complex internal structure, one should be selected close to the measured material in a group of test blocks to facilitate the calibration.

In order to solve this problem, the test block should have an internal structure in the same direction as the measured material, and the sound wave propagation direction in the test block should also be the same as the direction in the tested material.

In some cases, the sound velocity gauge of the known material can be used as a substitute for the reference test block, but this is only approximatelyIn lieu of some reference blocks, in some cases, the values in the sound velocity meter differ from the actual measurements due to differences in the physical and chemical conditions of the material. This method is often used to measure mild steel, but only as a rough measurement.

The TT130 ultrasonic Thickness Gauge has the function of measuring the speed of sound, so the speed of sound can be measured first, and then the speed of soundMeasurement is taken on the workpiece.

9.10 Several Methods in Measurements

a) Single measurement method: Measurement at a point.

b) Double measurement method: two measurements are made with the probe at one point, and the probe crosses the sound compartment in the two measurements

The plates should be perpendicular to each other. The minimum value in the reading is selected as the exact thickness of the material.

c) Multi-point measurement method: multiple measurements are carried out within a certain measurement range, and the minimum value is taken as the thickness of the materialValue.

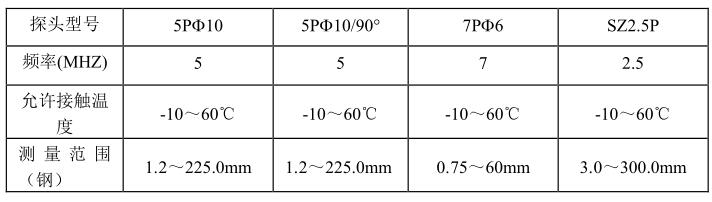

9.11 Probe Selection

9.12 The wear and tear of the crosstalk compartment plate of the probe will affect the measurement, and the probe should be replaced when the following phenomena occur.

1. When measuring different thicknesses, their measurements always show a certain value.

2. When the probe is plugged in, there is an echo indication or a measured value without measurement.

10. Prevention of measurement error

10.1 Ultra-thin materials

With any ultrasonic Thickness Gauge, the thickness of the material to be measured falls below the lower limit of the transducer's use, resulting in measurement errors, and if necessary, the minimum limit thickness can be measured using the block comparison method.

When measuring ultra-thin materials, sometimes an error result called "double refraction" occurs when the displayed reading is twice the actual thickness, and another error result is called "pulse envelope, cyclic jump", which results in a value that is larger than the actual thickness.

10.2 Rust spots, corrosion pits, etc., rust spots and pits on the other surface of the tested material will cause irregular changes in readings, and even no readings in extreme cases, and small rust spots are sometimes difficult to find. When a pit is found or when doubts are made, this area needs to be measured with great care, and the probe can be positioned at different angles for multiple tests.

10.3 Material Identification Errors

When an instrument is calibrated with one material and then tested with another, incorrect results will occur and care should be taken to select the correct sound velocity.

10.4 Wear and tear of the probe

The surface of the probe is made of acrylic resin, which will increase the roughness and reduce the sensitivity due to long-term use, and the user can use sandpaper or stone to smooth the surface of the probe with a small amount of sandpaper or stone to ensure the parallelism if it can be determined that the error is caused by this reason. If it is still unstable, the probe will need to be replaced.

10.5 Use of the "ZERO" key

This key should only be used to couple the probe to a standard block on the instrument panel for calibration, and not on any other block, as this will cause measurement errors.

10.6 laminated materials, composite materials

It is not possible to measure uncoupled laminated materials because ultrasound waves cannot penetrate uncoupled spaces. In addition, because ultrasonic waves cannot propagate at a uniform speed in composite materials, instruments that measure thickness by the principle of ultrasonic reflection are not suitable for measuring laminated materials and composite materials.

10.7 Effect of oxide layer on metal surface

Some metals can produce a dense oxide layer on its surface, such as aluminum, etc., this layer of oxide layer is tightly bonded with the matrix, and there is no obvious interface, but the propagation speed of ultrasonic waves in these two substances is different, so it will cause errors, and the thickness of the oxide layer is different, and the size of the error is also differentThe operator should have the ability to identify anomalous readings, which are usually caused by rust spots, corrosion pits, and internal defects in the material being measured. The solution can be found in Chapters 9 and 10.

10.9 Use and selection of couplant

The couplant is used as a high-frequency ultrasonic energy transfer between the probe and the material being measured. If the type is selected or used incorrectly, there is a risk that the error or the coupling mark will flicker, and the value cannot be measured. The couplant should be used in moderation and evenly coated.

It is important to select the right kind of couplant, and when used on smooth material surfaces, low viscosity couplants (e.g., randomly configured couplant, light motor oil, etc.) are suitable. When used on rough material surfaces, or on vertical surfaces and top surfaces, highly viscous couplants (e.g. glycerin paste, butter, grease, etc.) can be used.

Couplant formulations are available everywhere.

10.10 Probe sheath

When measuring the curved surface, it is recommended to use the curved probe sheath, which can accurately measure the thickness of the curved surface material of the pipeline, and the probe sheath is an optional part, which can be purchased from the sales department of Times Company.

11 Precautions

11.1 Automatic power off

TT130 ultrasonic Thickness Gauge in the process of use, in addition to two AA (5#) subtractive batteries, there is also a lithium battery, the role of the lithium battery is to provide uninterruptible power supply to the ROM data storage integrated chip in the host. If the gauge has not been automatically shut down, then take out two 5# batteries, the instrument will be forced to use the electric energy in the lithium battery, once the power of the lithium battery is exhausted, when the battery is replaced, the instrument can not store the test data, so it can not be used, so please note that the two 5# batteries must be taken out after the instrument is automatically shut down.

11.2 Cleaning of test blocks

Since the instrument is calibrated with a random test block, a couplant is applied, so please take care to prevent rust. Wipe the random test block clean after use. Do not sweat when the temperature is high. If it is not used for a long time, a little grease should be applied to the surface of the random test block to prevent rust, and when it is used again, the grease will be wiped off and it can work normally.

11.3 Cleaning of the chassis

Alcohol, diluent, etc. have a corrosive effect on the casing, especially the window, so when cleaning, gently wipe with a small amount of water.

11.4 Probe Protection

The probe surface is acrylic and sensitive to rescratching of rough surfaces, so it should be gently pressed in use. When measuring rough surfaces, minimize the scratching of the probe on the working surface.

When measuring at room temperature, the surface of the analyte should not exceed 60°C, otherwise the probe can no longer be used.

The adhesion of oil and dust will gradually age and break the probe cable, and the dirt on the cable should be removed after use.

11.5 Battery Replacement

After the low voltage indication sign appears, the battery should be replaced in time as follows:

a. Wait for the machine to shut down automatically

b. Open the battery compartment cover (press down the compartment cover with your thumb and exit again)

c. Take out the battery and put in a new battery, noting the polarity

When the instrument is not in use for a long time, the battery should be taken out to avoid battery leakage and corrosion of the battery box and pole piece.

11.6 Strictly avoid collisions, damp temperatures, etc.

12 repairs

12.1 If the error of the measured value is too large, please refer to Chapters 10 and 11.

12.2 If there are any of the following problems, please contact the maintenance department of Times Group:

A instrument device is damaged and cannot be measured.

B LCD display is not normal.

C When used normally, the error is too large.

D. Keyboard operation is out of order or out of order.

12.3 Since TT130 ultrasonic Thickness Gauge is a high-tech product, the maintenance work should be completed by professionally trained maintenance personnel, please do not disassemble and repair by yourself.